Rice straw fermentation treatment technology

A technology of rice straw and treatment process, applied in fermentation, biochemical equipment and methods, microorganisms, etc., can solve the problems of large stirring energy consumption, easy acidosis, uneven heat and mass transfer, etc., and achieve efficient and repeated green environmental protection resources The effect of utilization, stable methane concentration, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Example 1: Effect of fermentation pretreatment on gas production of rice straw

[0059] 1. Fermentation pretreatment of A. agaricus: prepare the microbial inoculum of A. agaricus by the above-mentioned method. The rice straw is pulverized by a pulverizer, and the particle size is 1-2 cm. Take 2 kg of straw, take the inoculum with a mass of 1% of the dry weight of the rice straw and urea with a mass of 0.5% of the dry weight of the rice straw, adjust the moisture of the straw to 65%, cover it with film, and pre-treat it for 3 days under the constant temperature of 35 °C as the experimental group. . The rest of the conditions were the same, and the same quality of inoculum after high temperature sterilization was added as the blank group.

[0060] 2. Mix the pretreated rice straw fermentation product of the experimental group and the blank group with the domesticated inoculum. Three groups of dry fermentation reactors were made in parallel.

[0061] The blank group wa...

Embodiment 2

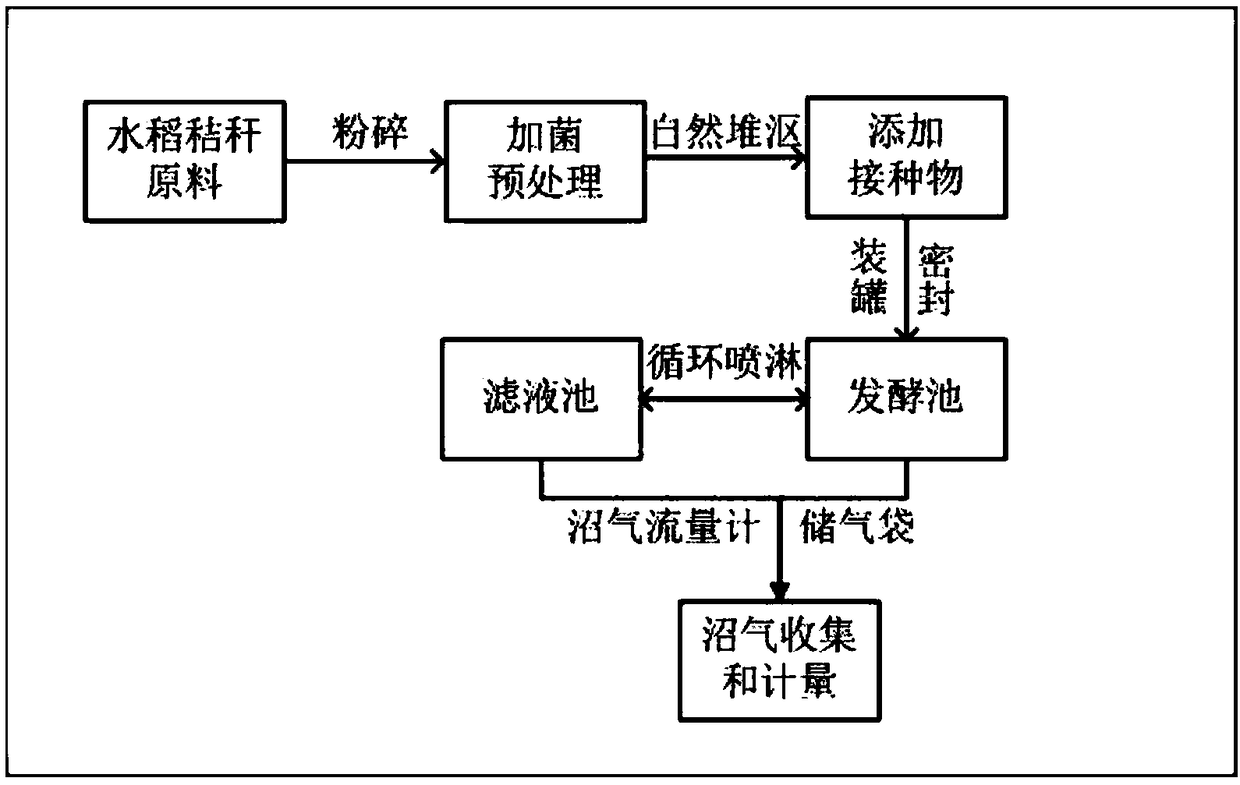

[0066] Example 2: Effect of fermentation method on gas production of rice straw

[0067] 1. The same pretreatment was performed on the experimental group and blank group of Example 2 using the method of the experimental group in Example 1.

[0068] 2. The pretreated experiments were assembled into a two-phase fermentation reactor, and the blank was assembled into a dry fermentation reactor. The blank group ran for a total of 55 days, and the experimental group ran for 45 days.

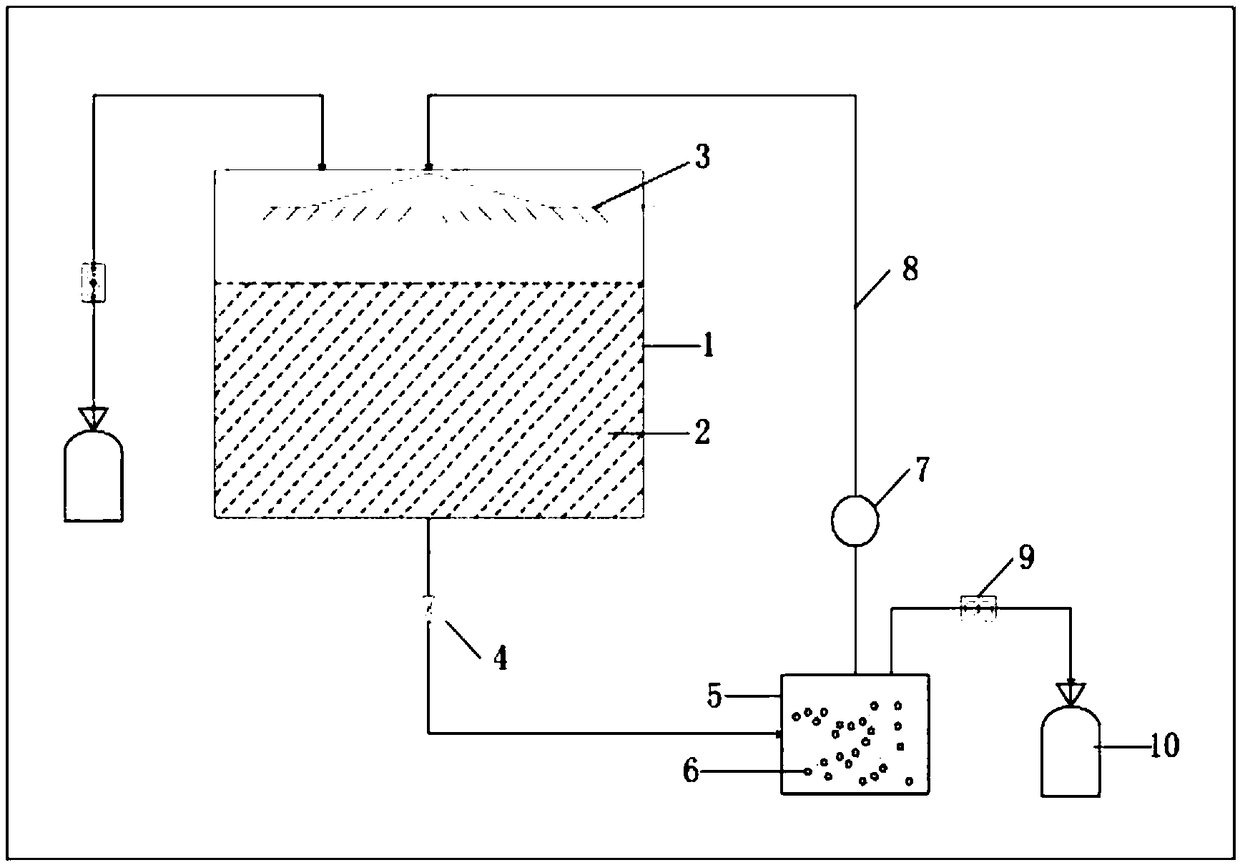

[0069] The two-phase reactor of the experimental group contained a filtrate spray device. After loading the fermentation substrate into the reactor, a volume of 1 / 3 the volume of the reactor solvent was added with deionized water. The deionized water infiltrates all the fermentation substrates under the action of gravity, and then leaches out, which is the water extract of the fermentation substrates to form a filtrate, and the filtrate enters the filtrate spray device to spray the fermentation subst...

Embodiment 3

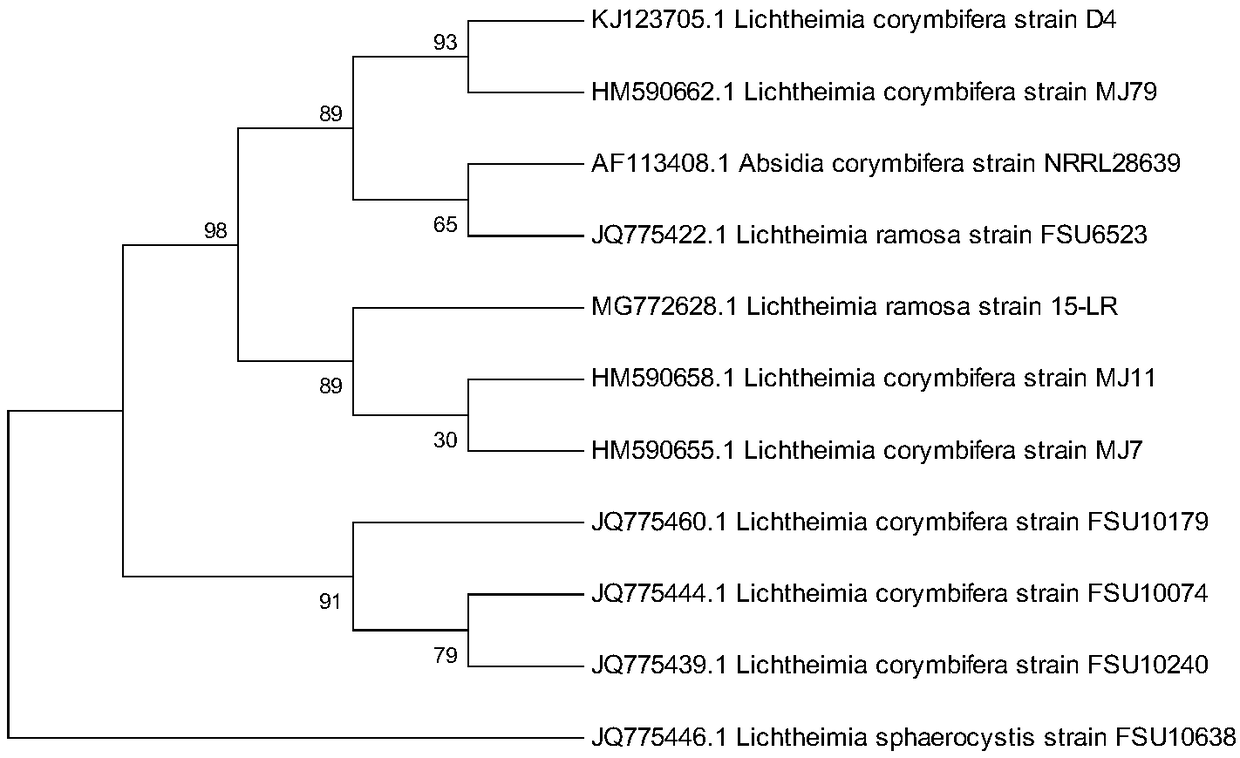

[0075] Example 3: Effects of different strains on gas production from rice straw

[0076] 1. Use the experimental group method of Example 2 to conduct experiments on the effect of different strains on the gas production of rice straw. The experimental treatment methods are exactly the same, only the strains used are different. Among them, the same amount of inoculum after high temperature sterilization was added as blank group. The specific treatment of each group is shown in Table 5.

[0077] Table 5 The specific treatment table of each group

[0078]

[0079]

[0080] 2. Put the pretreated groups into the two-phase fermentation reactor, spray the same amount of filtrate (3 times / day) to each group at regular intervals every day, and measure the gas production and methane gas concentration by sampling regularly. The specific results are shown in Table 6. The gas production rate in the table refers to the volume of biogas produced per kilogram of volatile solid matte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com