Preparation method of sweetpotato fermented Baijiu

A sweet potato and liquor technology, applied in the field of food processing, can solve the problems such as mixing of miscellaneous bacteria, unfavorable improvement of wine products by fermentation time and fermentation means, poor texture, etc., and achieves the effects of low production cost, simple production and processing technology, and pleasant aftertaste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

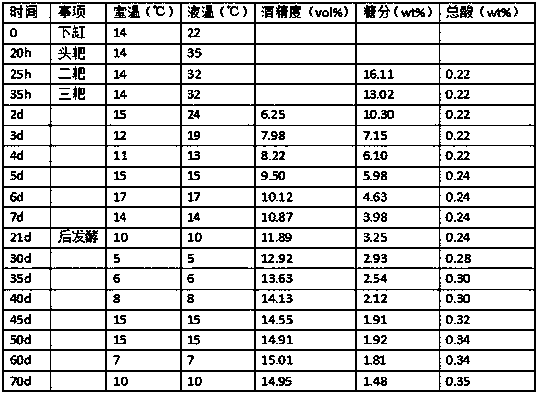

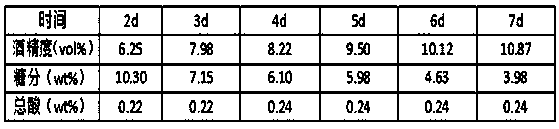

[0033] A method for preparing sweet potato shochu liquor, comprising the following steps: (1) Raw material processing: take sweet potatoes, wash, peel, cut into pieces, steam, and spread to cool; (2) Saccharification: add After the treatment, 7% wheat koji by weight of the raw material was added, and then cooled boiling water was added to make the ratio of material to liquid 1:1.5, and then mixed evenly, incompletely sealed for 3 days, the control conditions were temperature 35°C, temperature difference ± 2°C, pH 7.0, 8wt% inoculum is the best fermentation condition to obtain the saccharification mixture; (3) main fermentation: transfer the saccharification mixture into the fermenter, inoculate the mixed strains, the mixed strains include yeast and Bacillus subtilis, yeast The content of Bacillus subtilis is 5%, and the amount of mixed bacteria is 0.25% by weight. The temperature is controlled within 25~35°C through three times of raking process, and the time is 5 days. When the ...

Embodiment 2

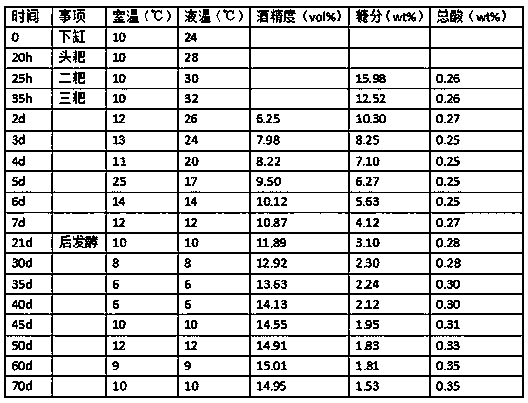

[0038] A method for preparing sweet potato shochu liquor, comprising the following steps: (1) Raw material processing: take sweet potatoes, wash, peel, cut into pieces, steam, and spread to cool; (2) Saccharification: add The glucoamylase of 7% of the weight of the raw material after the treatment is added to the boiled water after cooling to make the ratio of material to liquid 1:1.5, then mix evenly, and seal it incompletely for 5 days. The control conditions are temperature 35 ° C, temperature difference ± 2 ° C, pH 7.0, 8wt% inoculum is the best fermentation condition to obtain the saccharification mixture; (3) main fermentation: transfer the saccharification mixture into the fermenter, inoculate the mixed strains, the mixed strains include yeast and Bacillus subtilis, yeast The content of Bacillus subtilis is 9%, and the amount of mixed bacteria is 0.45% by weight. The temperature is controlled within 25~35°C through three times of raking process, and the time is 5 days. W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com