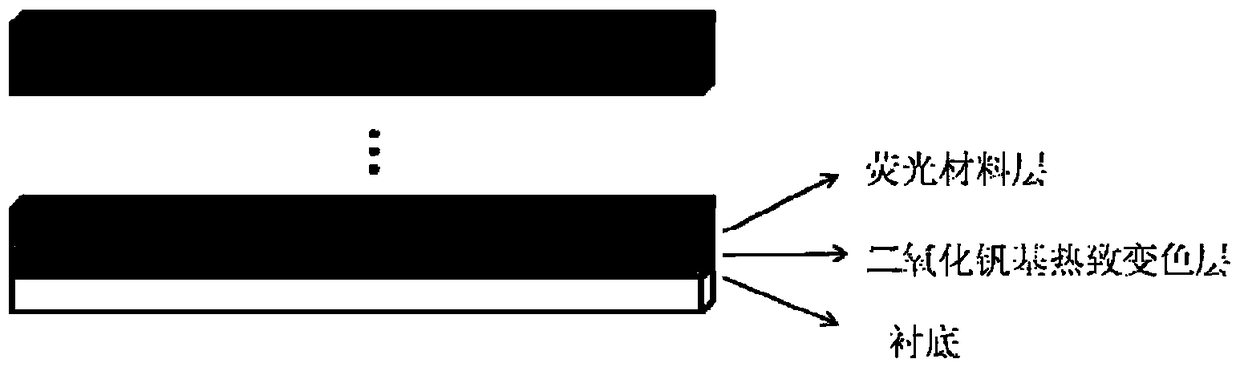

Vanadium dioxide-based fluorescent composite material and application thereof

A technology based on vanadium dioxide and fluorescent materials, which is applied in the direction of color-changing fluorescent materials, luminescent materials, chemical instruments and methods, etc., can solve the problems of high vacuum evaporation cost, weak film binding force, and difficulty in industrial production, and achieve ultraviolet The protective effect is obvious, the fluorescent color complementary effect is obvious, and the effect of easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Weigh 0.1g of vanadium dioxide particles and ultrasonically disperse them in 2g of ethanol to form a 5wt% dispersion, then add 4g of silicone resin to it, form a uniform slurry by magnetic stirring, and apply it on the substrate by scraping (glass, etc.), put it at room temperature for 2 hours until it solidifies (it can also be heated in an oven to accelerate its curing), and a vanadium dioxide-based thermochromic film is obtained with a thickness of 80 μm and a yellow color.

[0061] Dissolve OB fluorescent whitening agent in toluene to form a 5wt% solution, take 2g of the dispersion and add 2.5g of polycrystalline resin and 1g of silicone resin to it, stir magnetically to form a uniform slurry, and scrape it onto the pre- On the prepared vanadium dioxide-based thermochromic film, after being cured, the film (with a total thickness of 200 μm) can emit blue light under sunlight irradiation.

Embodiment 2

[0063] According to the mass ratio, vanadium dioxide particles: quantum dots CdSe@ZnS=1:1 are added in the ball mill, and toluene is used as a solvent to be equipped with a suitable dispersant to obtain a mixed dispersion of vanadium dioxide particles and photosensitive powder, and its concentration is 5wt %, then take 2g of the dispersion and add 4g of silicone resin to it, form a uniform slurry by magnetic stirring, apply it on the substrate by scraping, and wait for it to solidify to obtain a vanadium dioxide base with a thickness of 120μm. Fluorescent composite film.

Embodiment 3

[0065] Prepare a vanadium dioxide-based thermochromic film according to Example 1, with a thickness of 80 μm;

[0066] The quantum dot powder CdSe@ZnS is formed into a 5wt% dispersion by ball milling with toluene as a solvent. Take 0.5, 1, 3, and 4 g of the dispersion respectively, and add 2.5 g of polycrystalline resin and 1 g of silicone resin to it, and magnetically stir to form uniform slurry, and scrape-coat it on the pre-prepared vanadium dioxide-based thermochromic film to obtain a film with adjustable luminous brightness (the total thickness is 200 μm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com