Vulcanizing activator and preparation method thereof

A technology of vulcanization activator and zinc oxide, applied in the field of vulcanization activator, can solve the problems of difficult to maintain stable product performance, cumbersome preparation process, limited zinc reduction ability, etc., and achieves the effects of low price, simple synthesis process and reduction of specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

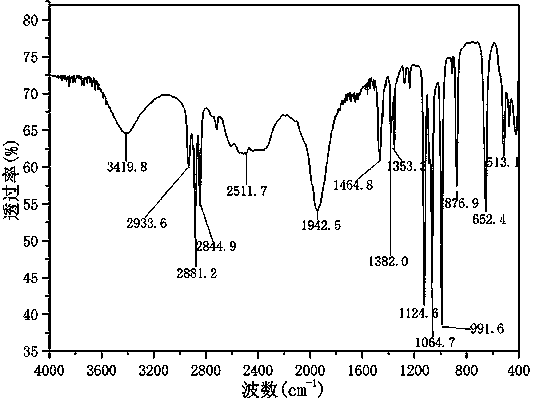

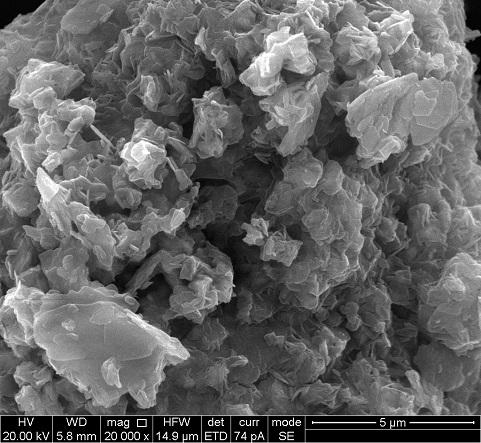

[0018] Add 295mmol (24g) of zinc oxide, 1.5g of benzoic acid and 100g of methylcyclohexane into a 250mL three-necked flask equipped with a stirrer, thermometer, reflux condenser and water separator, stir for 30min and then add 250mmol (23g) of glycerin, Heat up to 102°C with stirring, reflux for 240 minutes, cool, filter with suction, and dry to obtain 41.4 g of white powder with sulfuration activity and zinc content of 46.1%. The infrared spectrum and the scanning electron micrograph of the vulcanization activator of the present embodiment are shown in figure 1 and figure 2 shown.

Embodiment 2

[0020] Add 295mmol (24g) of zinc oxide, 1.5g of benzoic acid and 100g of D30 solvent oil into a 250mL three-necked flask equipped with a stirrer, thermometer, reflux condenser and water separator, stir for 30min, then add 250mmol (23g) of glycerin, and stir Raise the temperature to 130~134°C, reflux for 150min, cool, filter with suction, and dry to obtain 42.1g of white powder with sulfuration activity and zinc content of 45.6%.

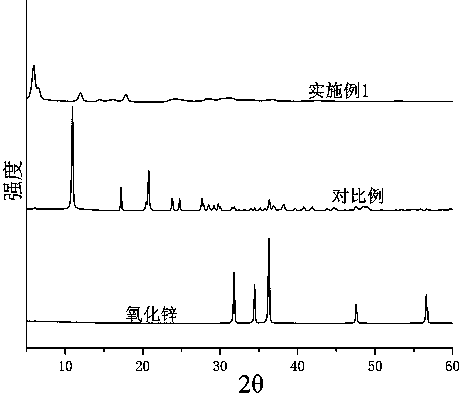

[0021] The comparison of embodiment 1, comparative example (CN105906473A embodiment 1) and the X-ray pattern collection of 99.7% indirect method zinc oxide sees image 3 shown. It can be seen from the spectrum that the lattice regularity of the prepared vulcanization activator is not as good as zinc oxide and zinc glycerol, and the positions of the diffraction peaks are different from those of zinc oxide and zinc glycerol, and it is not the superposition of the two diffraction peaks. It can be seen that A new type of structure.

[0022] The zinc ox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com