Semitrailer for transporting power tank

A technology for semi-trailers and powder tanks, which is applied to goods transport vehicles, oil tankers, transport objects, etc., can solve the problems of single wheel connection structure, deformation of the tank body, deformation of the connection position between the tank body and the mounting frame, etc., so as to avoid deformation. Even cracking, improving stability, and ensuring the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with specific embodiments. This embodiment provides detailed implementation methods and specific operation processes on the premise of the technical solution of the present invention.

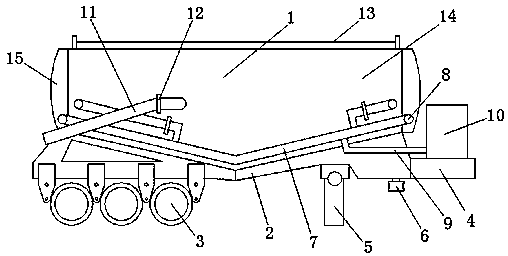

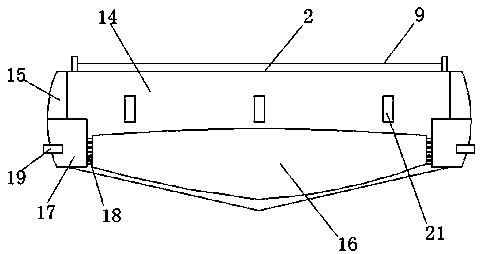

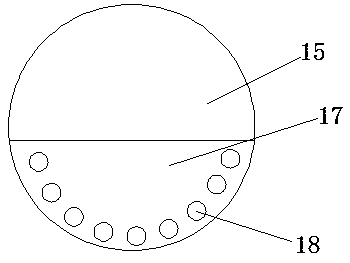

[0020] As shown in the figure, the present invention is a powder tank transport semi-trailer, which includes a tank body 1, a mounting frame 2 arranged at the bottom of the tank body 1, and a wheel 3 arranged at the bottom of the tail end of the mounting frame 2. The tank body 1 is arranged along the The bottom in the length direction is a V-shaped structure, and the top structure of the mounting frame 2 matches the V-shaped structure at the bottom of the tank body 1. The top of the mounting frame 2 is close to the bottom of the tank body 1 and connected with the tank body 1 as a whole. The bottom of the tail end is a horizontal structure, and the inside of the tail end of the mounting frame 2 has a cavity, the cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com