Technology for die releasing of MDI artificial board through special paper

A technology for special paper and wood-based panels, applied in special paper, paper, application and other directions, can solve the problems of not easy to release wood-based panels, poor appearance quality of slabs, affecting the yield of finished products, etc., to improve the demoulding efficiency and demoulding. Quality, very easy to cross-link curing, good water resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

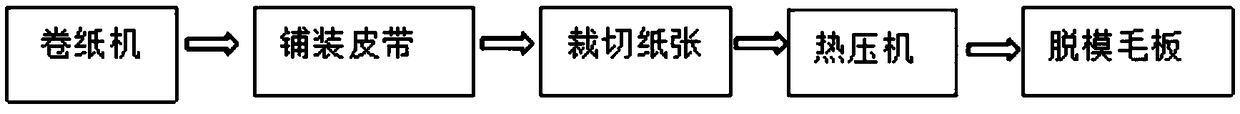

[0018] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following embodiments will specifically illustrate the process of using special paper for MDI wood-based panel demoulding in the present invention in conjunction with the accompanying drawings.

[0019] The process of using special paper for MDI wood-based panel demoulding includes the following steps:

[0020] Step 1: The raw materials in the silo are paved on the paving belt to form MDI wood-based panel slabs.

[0021] Step 1: Simultaneously with step 1. The special paper is paved continuously through the winding machine, and the synchronous operation of the paving belt and the winding machine is controlled, so that the special paper and the paving belt pass through the paving machine, slab scale, and pre-pressing machine synchronously.

[0022] Step 3: When the distance between the special paper and the pavement belt is 1mm to 3mm, it is consid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com