Tweeter part assembly system

A technology of parts assembly and tweeter, which is applied in assembly machines, vehicle parts, transportation and packaging, etc., can solve the problems of unfavorable factories on product management, production without seamless connection, and affecting production rhythm, etc., so as to reduce the rate of defective products, Improve the degree of automation and ensure the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

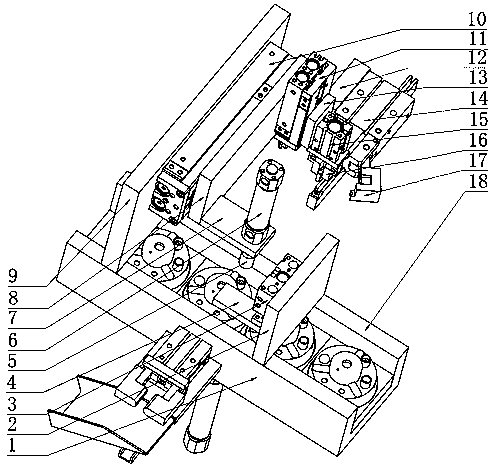

[0032]The initial state of the lower pressure cylinder 3 of the horn case is that the pressure plate 4 of the lower pressure cylinder is lifted. At this time, the horn housing can pass through in the slideway, and the working state is that the pressure plate 4 of the lower pressure cylinder compresses the housing. The initial state of the screw clamping cylinder 15 is located directly above the screw feeding trough, the initial state of the correction cylinder air claw 17 is the loose state, the working state is the closed state of clamping the screw, and the initial state of the screw correction cylinder 14 is the open state , the working state is the closed state of clamping the screw, the initial state of the screw extraction cylinder 11 is located directly above the screw feeding groove, the working state is that the screw feeding level is at the lowest position to pick up the screw, and then rises to the highest position, and the screw traversing cylinder 10 Transport down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com