Electric drill fixing bracket

A technology for fixing brackets and electric drills, which can be used in portable drilling rigs, drilling/drilling equipment, workbenches, etc., to solve problems such as occlusion of sight, low safety, and easy arm soreness, so as to achieve accurate drilling positions and reduce work volume, improve safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

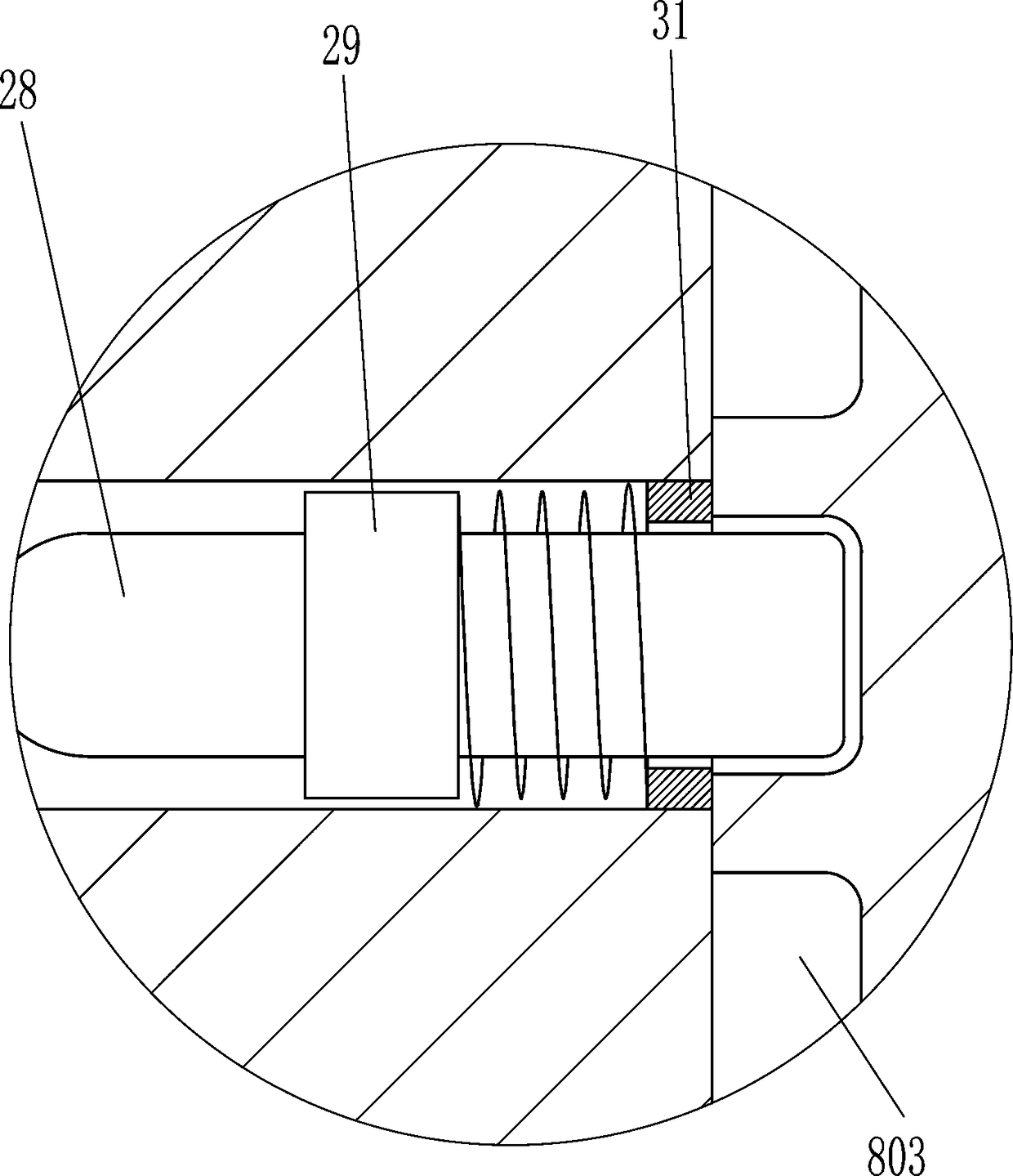

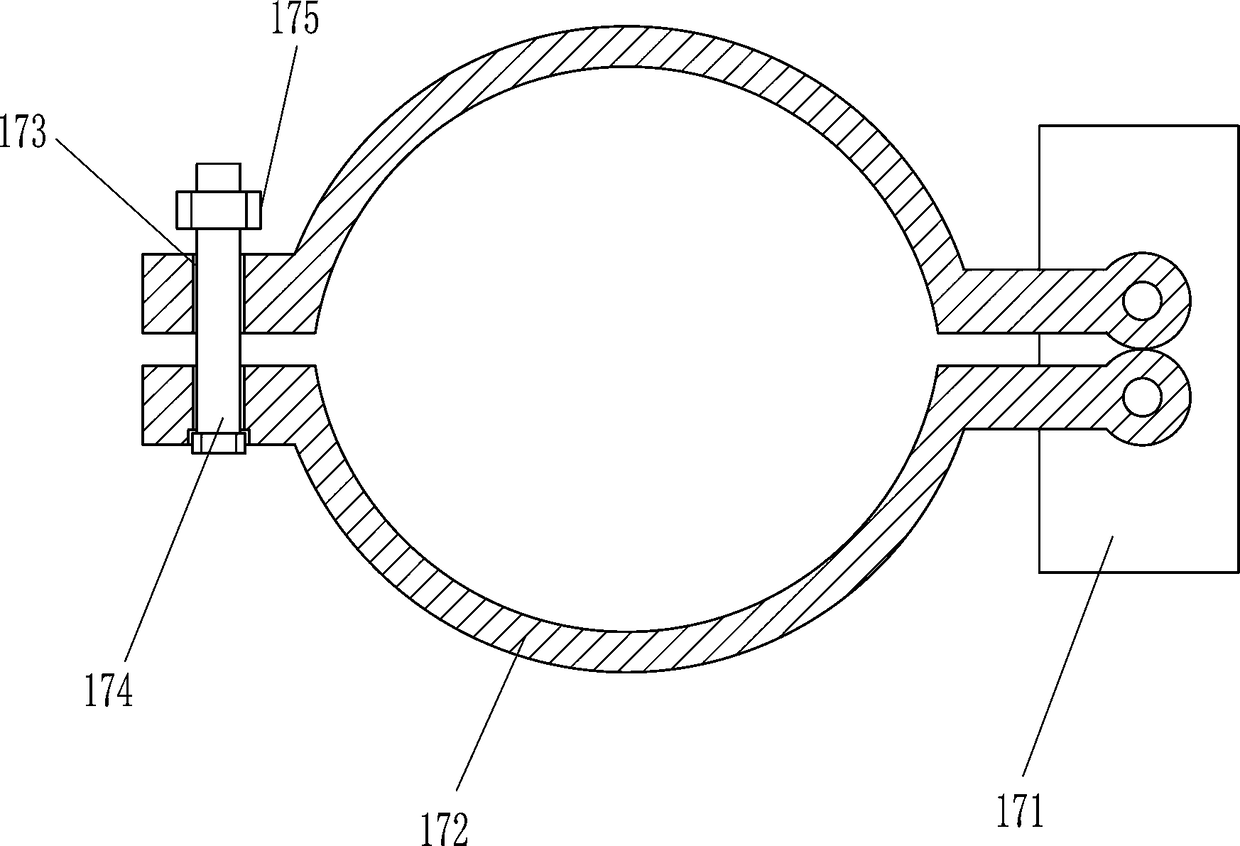

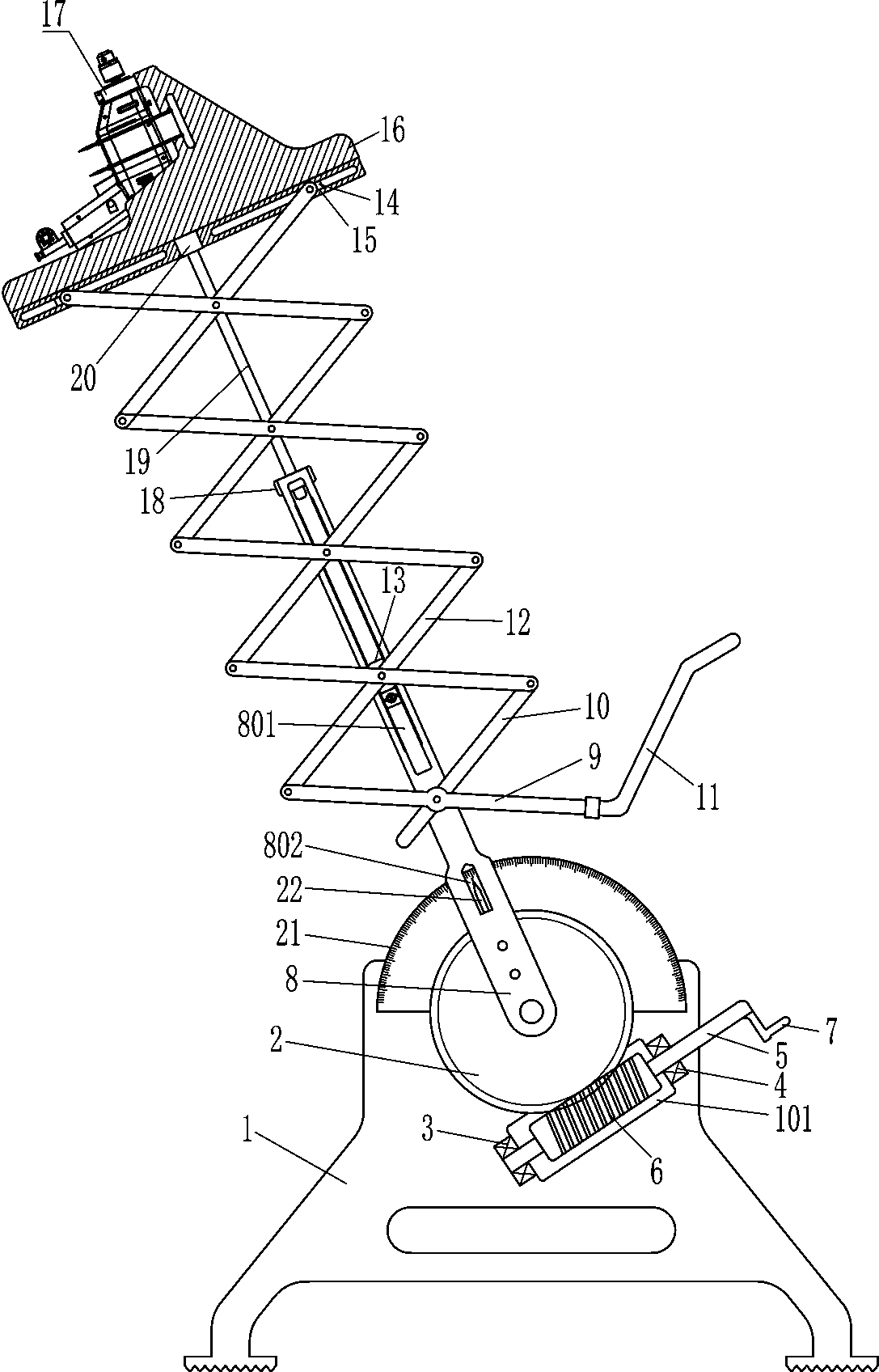

[0017] An electric drill fixing bracket, such as Figure 1-2 As shown, it includes a frame 1, a worm wheel 2, a first bearing 3, a second bearing 4, a rotating shaft 5, a worm screw 6, a handle 7, a straight plate 8, a first connecting rod 9, a second connecting rod 10, a handle 11, Scissor lifting frame 12, first slide block 13, guide plate 14, second slide block 15, mounting plate 16 and locking mechanism 17, the front side upper part of frame 1 is connected with worm gear 2 in rotation, the front side of frame 1 A first bearing 3 is installed on the lower side, a second bearing 4 is installed on the right side of the front side of the frame 1, a rotating shaft 5 is installed between the first bearing 3 and the second bearing 4, a worm 6 is installed on the rotating shaft 5, and a worm 6 Engaged with the worm wheel 2, the right end of the rotating shaft 5 is fixed with a turning handle 7 that can make the worm 6 rotate. The chute 801 of guiding effect, the sliding type in t...

Embodiment 2

[0019] An electric drill fixing bracket, such as Figure 1-2 As shown, it includes a frame 1, a worm wheel 2, a first bearing 3, a second bearing 4, a rotating shaft 5, a worm screw 6, a handle 7, a straight plate 8, a first connecting rod 9, a second connecting rod 10, a handle 11, Scissor lifting frame 12, first slide block 13, guide plate 14, second slide block 15, mounting plate 16 and locking mechanism 17, the front side upper part of frame 1 is connected with worm gear 2 in rotation, the front side of frame 1 A first bearing 3 is installed on the lower side, a second bearing 4 is installed on the right side of the front side of the frame 1, a rotating shaft 5 is installed between the first bearing 3 and the second bearing 4, a worm 6 is installed on the rotating shaft 5, and a worm 6 Engaged with the worm wheel 2, the right end of the rotating shaft 5 is fixed with a handle 7 that can rotate the worm 6, and the straight plate 8 is arranged on the front side of the worm w...

Embodiment 3

[0022] An electric drill fixing bracket, such as Figure 1-2 As shown, it includes a frame 1, a worm wheel 2, a first bearing 3, a second bearing 4, a rotating shaft 5, a worm screw 6, a handle 7, a straight plate 8, a first connecting rod 9, a second connecting rod 10, a handle 11, Scissor lifting frame 12, first slide block 13, guide plate 14, second slide block 15, mounting plate 16 and locking mechanism 17, the front side upper part of frame 1 is connected with worm gear 2 in rotation, the front side of frame 1 A first bearing 3 is installed on the lower side, a second bearing 4 is installed on the right side of the front side of the frame 1, a rotating shaft 5 is installed between the first bearing 3 and the second bearing 4, a worm 6 is installed on the rotating shaft 5, and a worm 6 Engaged with the worm wheel 2, the right end of the rotating shaft 5 is fixed with a handle 7 that can rotate the worm 6, and the straight plate 8 is arranged on the front side of the worm w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com