Composite instant black tea and preparation method thereof

A technology for instant black tea and black tea, applied in the field of black tea, can solve the problems of loss, poor heat resistance of nutrients, single variety, etc., and achieve the effects of functional synergy, improving instant properties, and promoting appetite.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

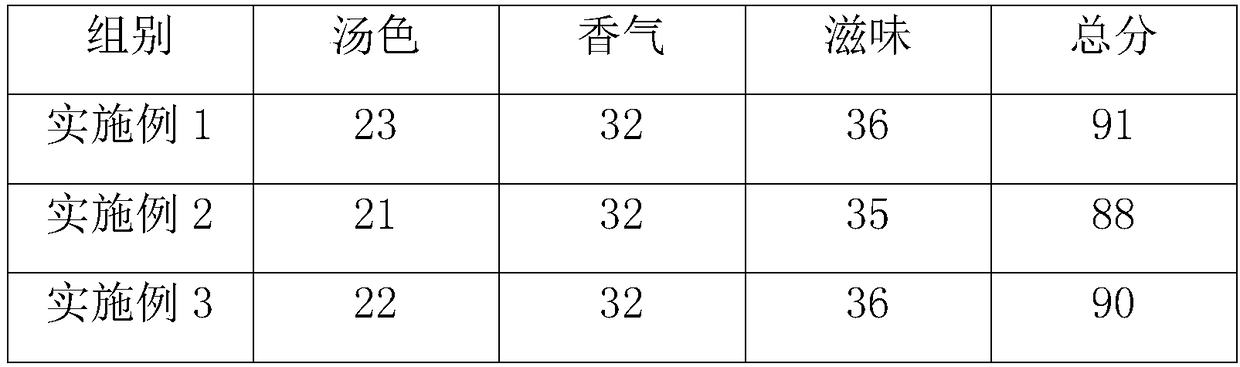

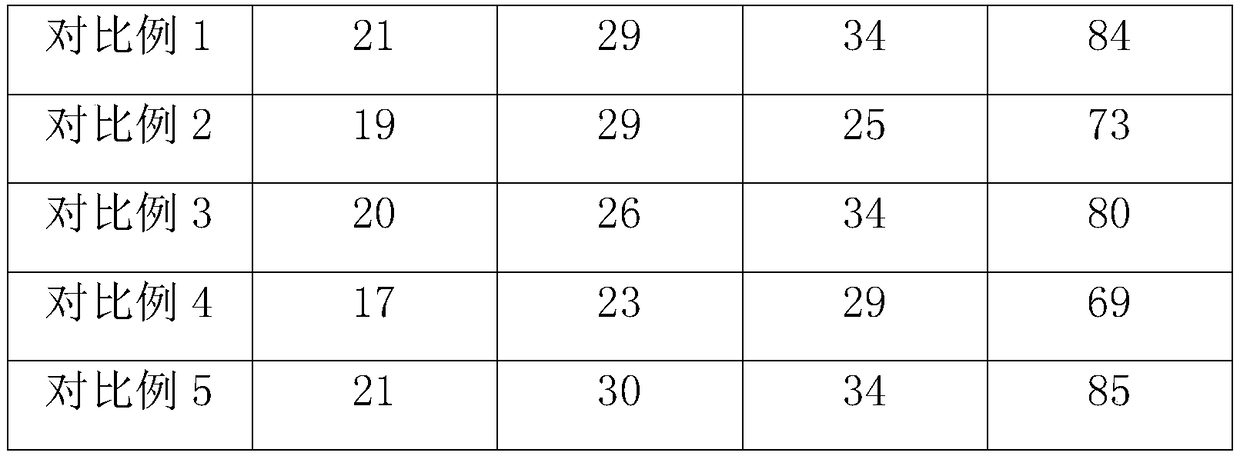

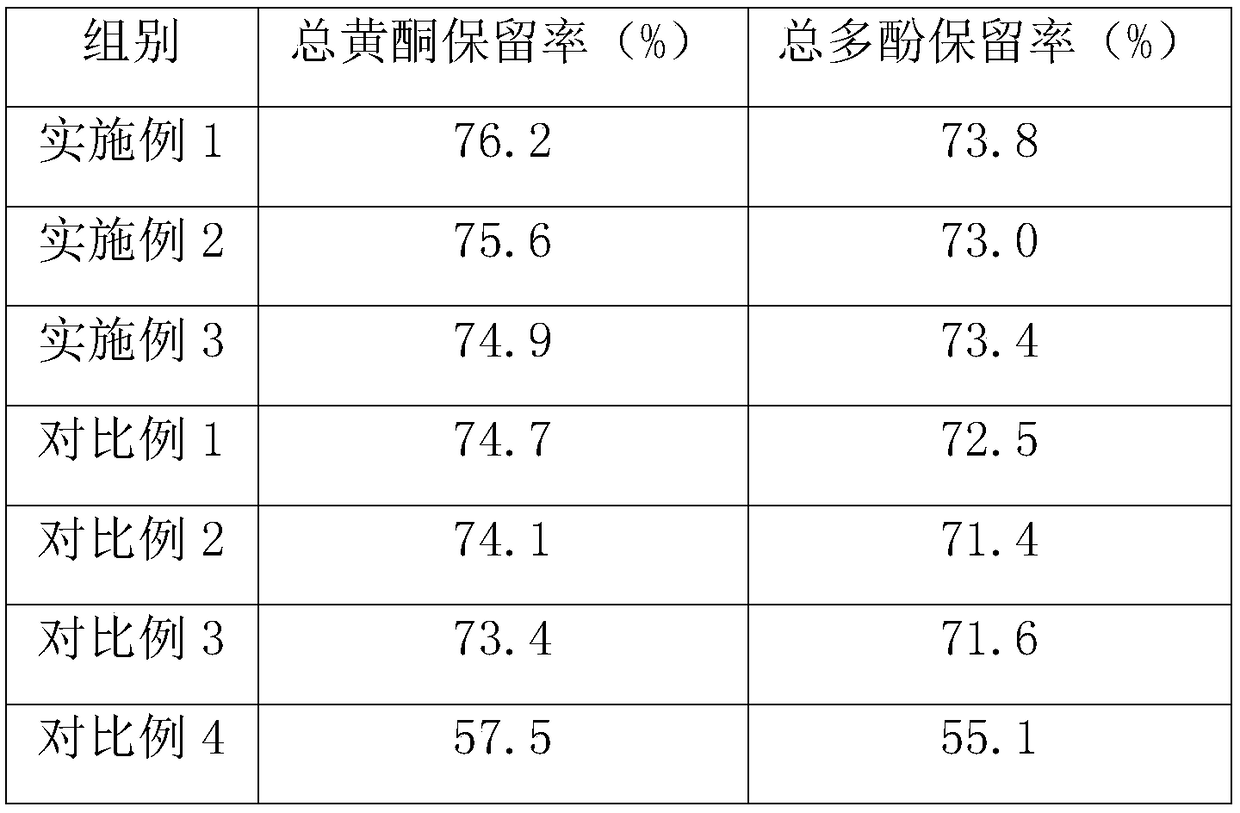

Examples

Embodiment 1

[0025] The preparation method of the compound instant black tea beverage of the present embodiment, carries out the following steps successively:

[0026] 1), the main ingredients are composed of the following components by weight: 15 parts of black tea, 11 parts of light bamboo leaves, 6 parts of kapok, 4 parts of tangerine peel, 4 parts of wolfberry, and 3 parts of licorice;

[0027] 2) Add the main ingredients into pure water, heat and extract for 16-17 minutes to obtain the extraction juice, wherein the extraction temperature is controlled at 70-85°C, and the weight ratio of water to main ingredients is 28:1;

[0028] 3) The extract obtained in step 2) is selected from a ceramic membrane tube with a pore size of 0.5 μm, and the ceramic membrane is filtered under the conditions of 0.2 Mpa and 20-25° C. to obtain the filtrate;

[0029] 4), dissolve the composite wall material in pure water, add it into the filtrate obtained in step 3) after homogenization, and prepare microc...

Embodiment 2

[0036] 1), the main ingredients are composed of the following components by weight: 14 parts of black tea, 10 parts of bamboo leaves, 5 parts of kapok, 3 parts of tangerine peel, 3 parts of wolfberry, and 2 parts of licorice;

[0037] 2) Add the main ingredients into pure water, heat and extract for 16-17 minutes to obtain the extraction juice, wherein the extraction temperature is controlled at 70-85°C, and the weight ratio of water to main ingredients is 28:1;

[0038] 3) The extract obtained in step 2) is selected from a ceramic membrane tube with a pore size of 0.5 μm, and the ceramic membrane is filtered under the conditions of 0.2 Mpa and 20-25° C. to obtain the filtrate;

[0039] 4), dissolve the composite wall material in pure water, add it into the filtrate obtained in step 3) after homogenization, and prepare microcapsules by ultrasonic, wherein the pure water is 10% of the weight of the extract, and the wall material is selected from carboxymethyl-β - Cyclodextrin, ...

Embodiment 3

[0046] 1), the main ingredients are composed of the following components by weight: 16 parts of black tea, 12 parts of light bamboo leaves, 7 parts of kapok, 5 parts of tangerine peel, 5 parts of wolfberry, 4 parts of licorice;

[0047] 2) Add the main ingredients into pure water, heat and extract for 16-17 minutes to obtain the extraction juice, wherein the extraction temperature is controlled at 70-85°C, and the weight ratio of water to main ingredients is 28:1;

[0048] 3) The extract obtained in step 2) is selected from a ceramic membrane tube with a pore size of 0.5 μm, and the ceramic membrane is filtered under the conditions of 0.2 Mpa and 20-25° C. to obtain the filtrate;

[0049] 4), dissolve the composite wall material in pure water, add it into the filtrate obtained in step 3) after homogenization, and prepare microcapsules by ultrasonic, wherein the pure water is 10% of the weight of the extract, and the wall material is selected from carboxymethyl-β - Cyclodextrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com