Noise reduction equipment for workshop dry-type transformers

A dry-type transformer and noise reduction technology, which is applied in transformer/inductor parts, transformer/inductor noise damping, transformer/inductor cooling, etc., can solve the problem that the noise reduction equipment cannot adjust the ventilation effect of the transformer in time, and achieve Enhanced heat dissipation effect, reduced noise, and increased exposed area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

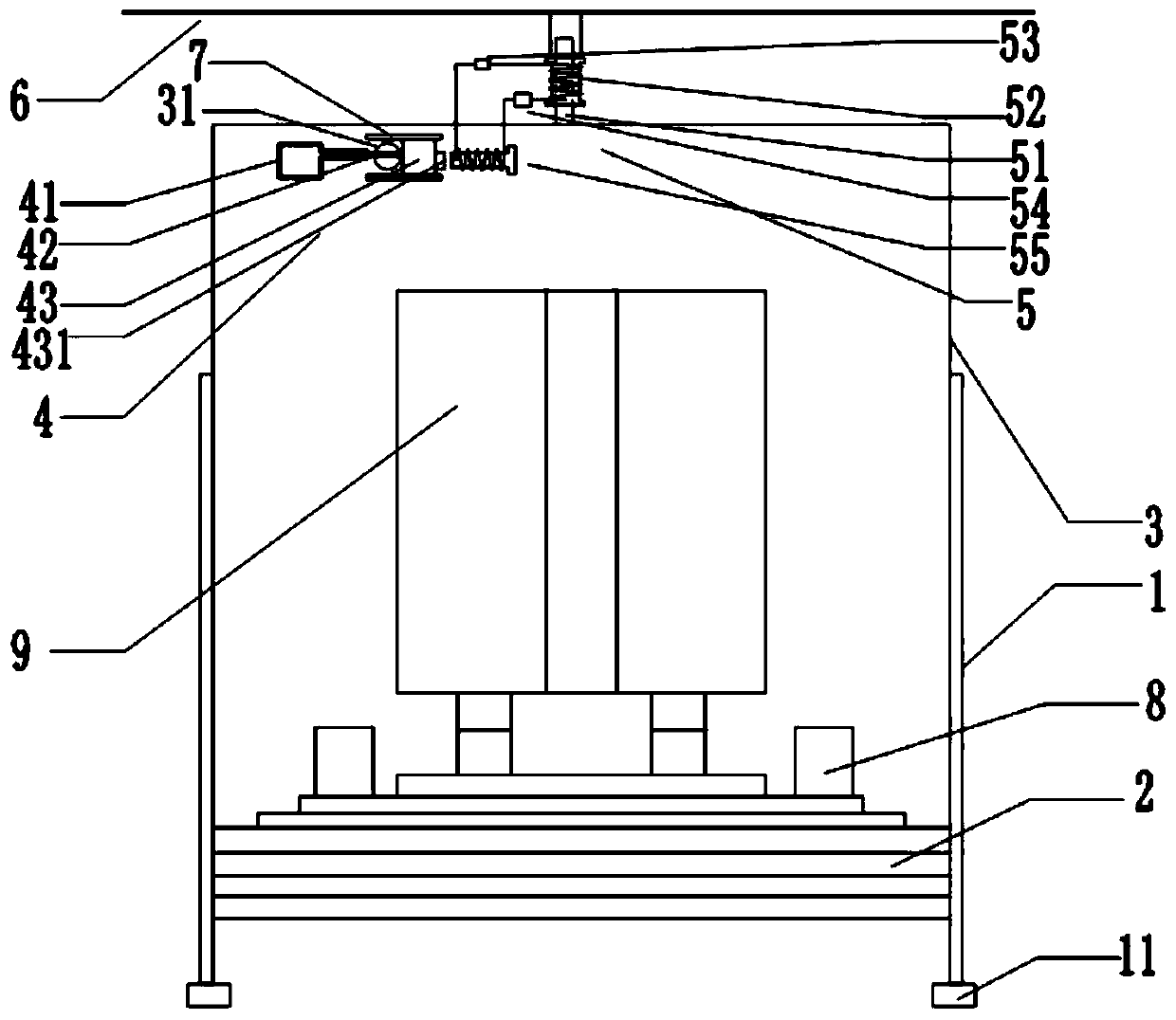

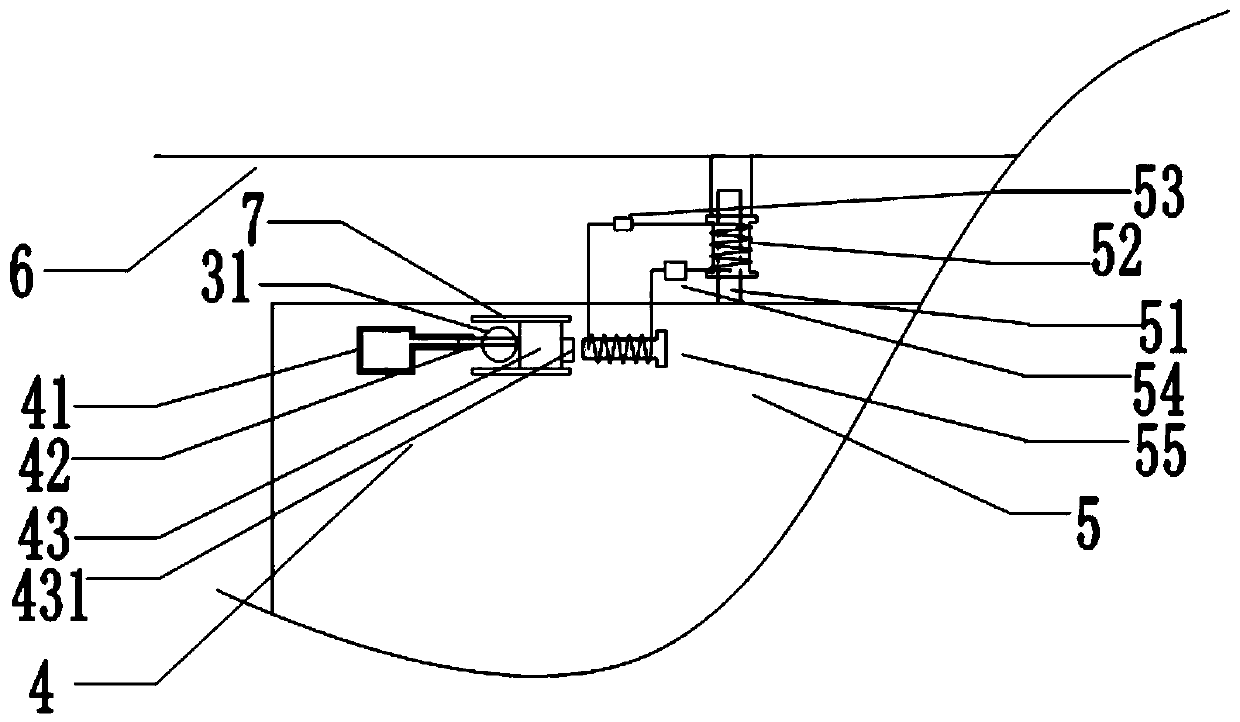

[0031] Further detailed explanation through specific implementation mode below:

[0032] The reference signs in the drawings of the specification include: bracket 1, shock absorbing spring 11, shock absorbing pad 2, housing 3, ventilation hole 31, temperature measuring mechanism 4, temperature measuring bottle 41, temperature measuring rod 42, windshield 43. Magnet block 431, electromagnetic mechanism 5, magnet rod 51, solenoid 52, resistor 53, diode 54, metal rod 55, ceiling 6, slide rail 7, fan 8, dry transformer 9.

[0033] Such as figure 1 , figure 2 As shown, the present invention provides a noise reduction device for a workshop dry-type transformer, including a bracket 1 , a housing 3 , a shock pad 2 , a temperature measuring mechanism 4 , an electromagnetic mechanism 5 , a canopy 6 and a fan 8 .

[0034] The bracket 1 is made of angle steel, and the bracket 1 is welded by four vertical beams and four beams; the shell 3 is a cuboid, and the shell 3 is welded on the br...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com