Machine automatic management system and method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the content of the present invention more comprehensible, the following specific examples are given as examples in which the present invention can indeed be implemented. In addition, wherever possible, components / members / steps with the same reference numerals in the drawings and embodiments represent the same or similar components.

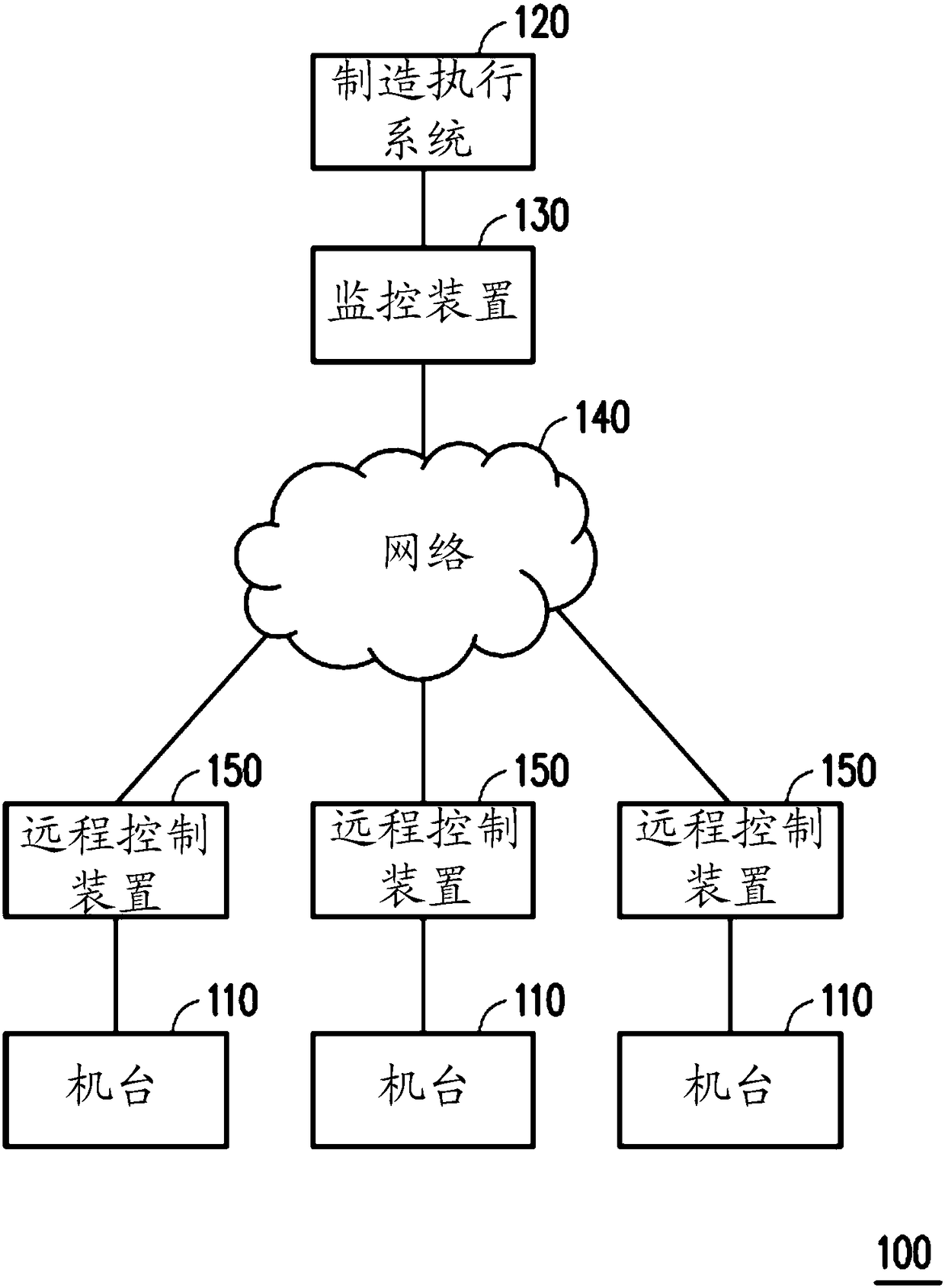

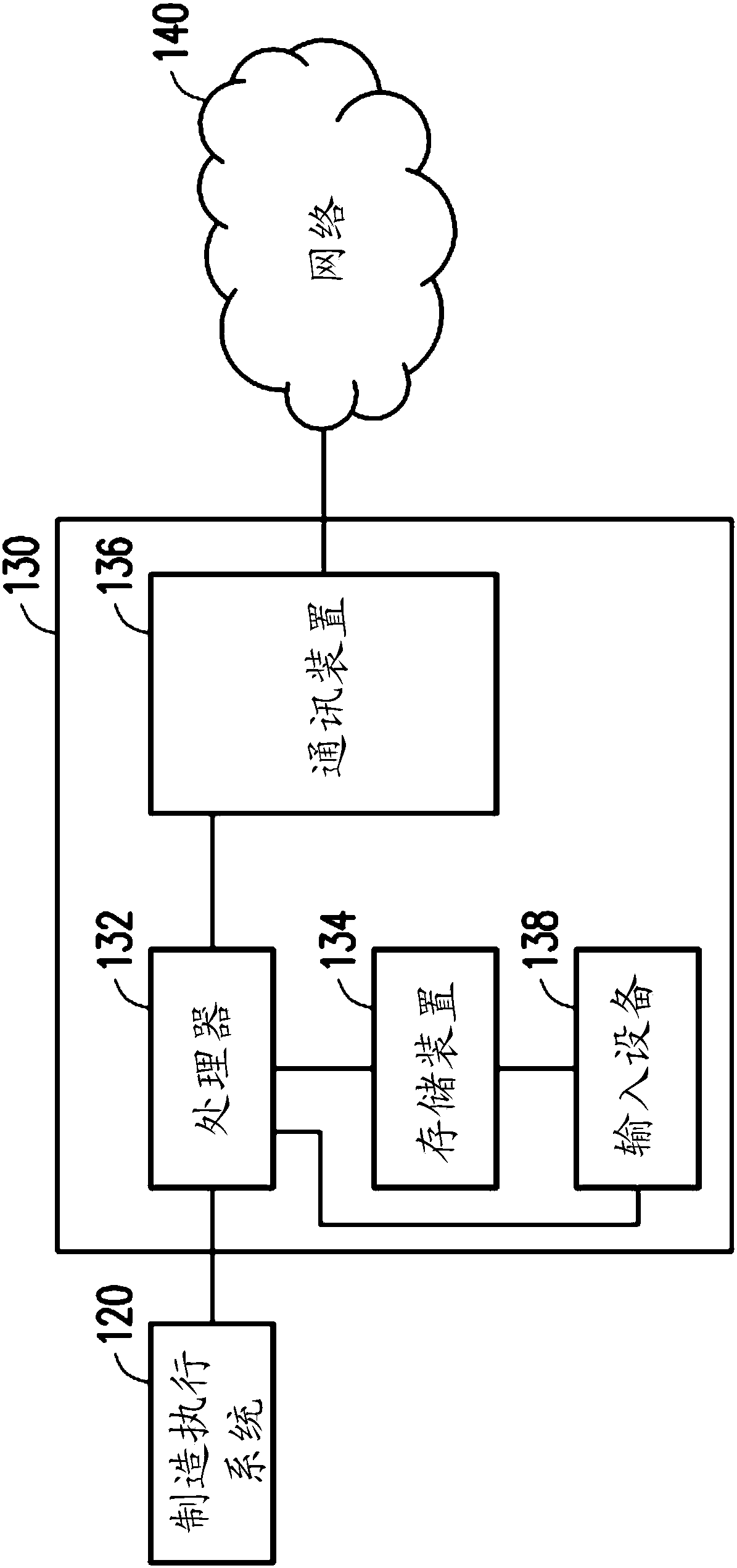

[0039] figure 1 It is a schematic diagram of a machine automation management system according to an embodiment of the present invention. Please refer to figure 1 , the machine automation management system 100 includes a plurality of machines 110, a manufacturing execution system (manufacturing execution system, MES) 120, a plurality of remote control devices 150, and a monitoring device 130, wherein, the present embodiment takes three machines as an example. To illustrate, but not limited thereto, in other embodiments, the machine automation management system 100 may include more machines 110 . In this embodiment, each m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com