Electroplating cathode hanging device

A hanger and cathode technology, applied in the electrolysis process, electrolysis components, current conduction devices, etc., can solve the problems of hanger main body damage, easy leakage, easy heat and burnt, etc., to prolong service life, improve coating quality, Guaranteed strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

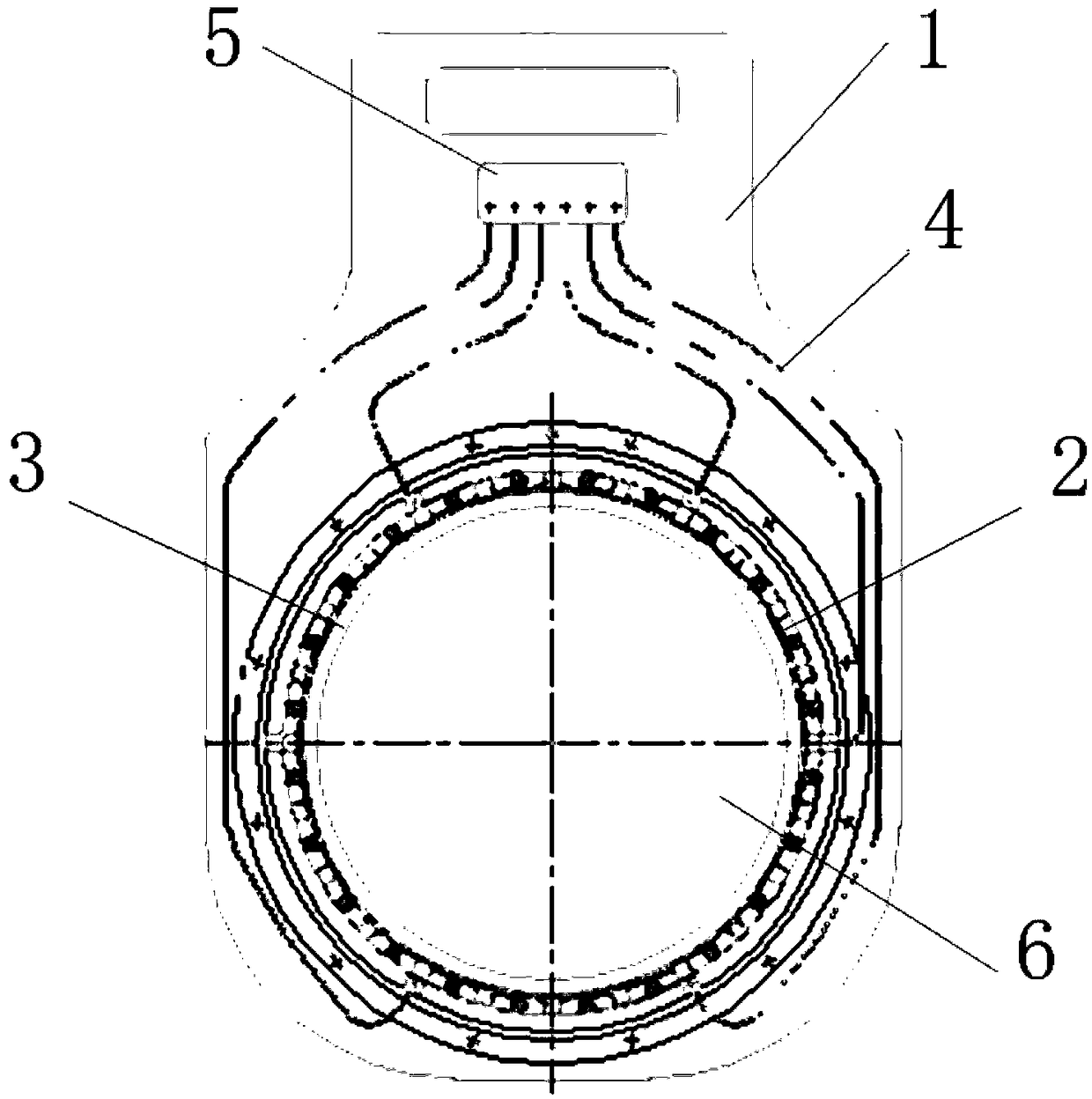

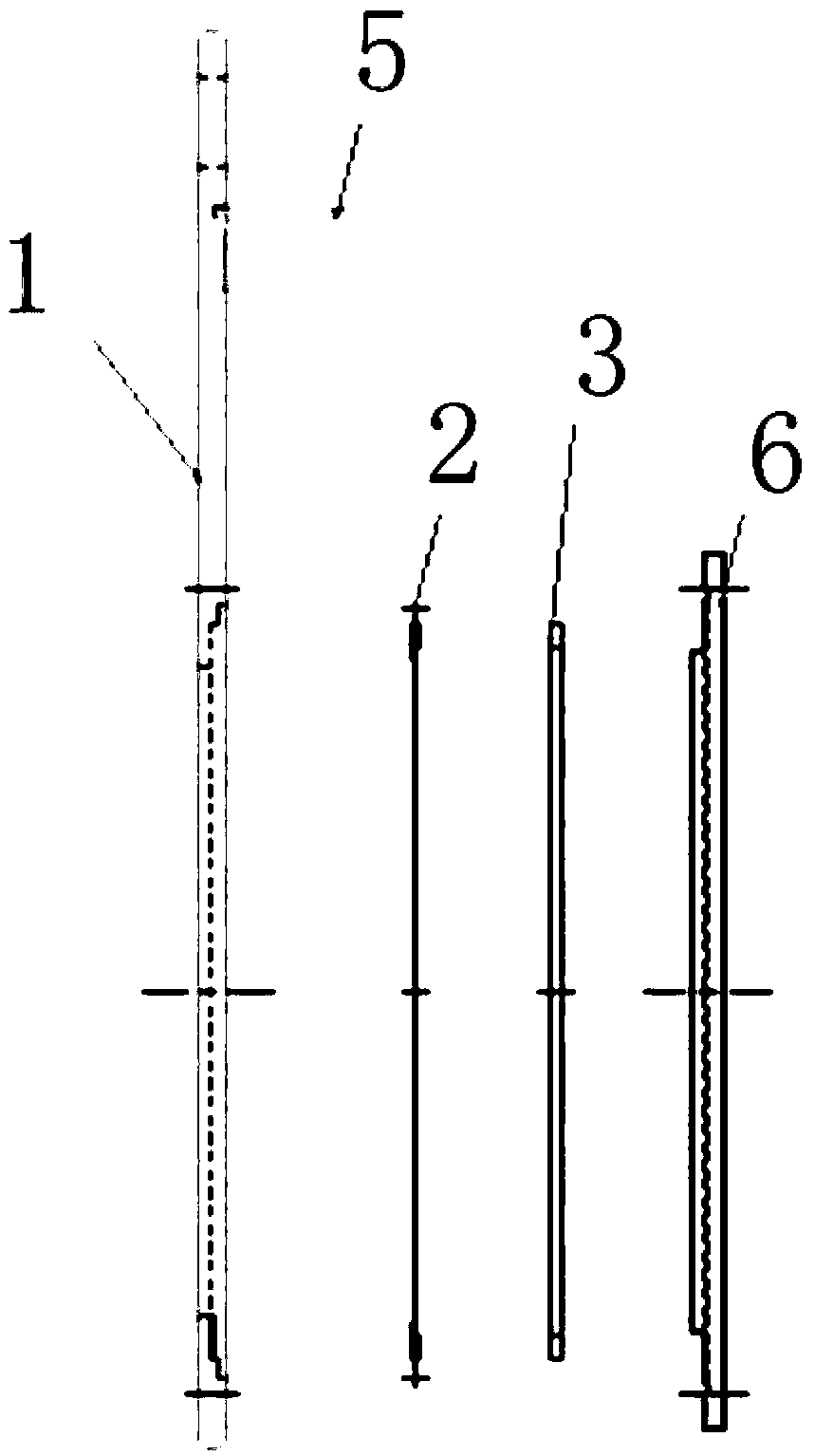

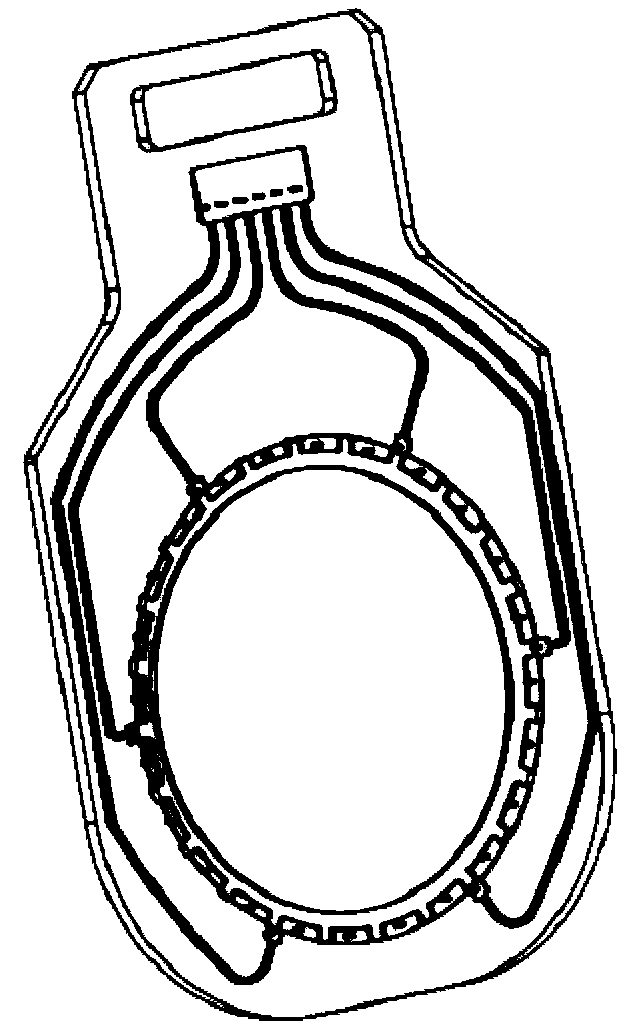

[0029] Such as Figure 1-7 As shown, the electroplating cathode hanger has a structure including a hanger main body 1, a conductive sheet 2, a pressing plate 3, a conductive thread 4, a conductive hook 5 and a rear cover 6, wherein the lower part of the hanger main body 1 is provided with a shape matching with the conductive sheet 2. Mounting groove, the conductive sheet 2 is pressed into the mounting groove on the main body of the hanger 1 through the pressure plate 3 and fixedly connected by A screws, the outer surface of the conductive sheet 2 is covered with fluororubber, the edge of the conductive sheet 2 is provided with bumps, and the main body of the hanger 1 The upper part is provided with a conductive hook 5, and the main body of the hanger 1 is provided with several grooves matching the shape of the conductive wire. The conductiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com