Preparation method of carboxymethyl chitosan film

A technology of carboxymethyl chitosan film and carboxymethyl chitosan, which is applied in the field of preparation of carboxymethyl chitosan film, can solve the problem that carboxymethyl chitosan cannot use conventional film-making process and film-making process Preparation, difficult film formation and other problems, to achieve the effect of green raw materials, wide application and strong antibacterial property

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

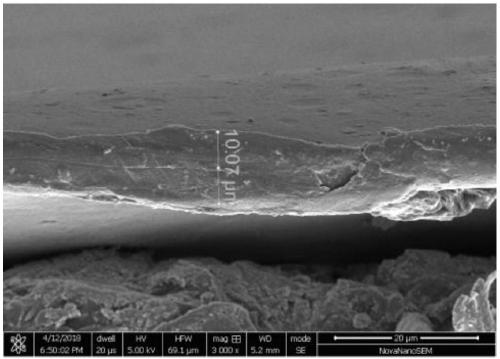

[0021] Take 0.3g of carboxymethyl chitosan and add it to 99.7ml of water to obtain a 0.3% carboxymethyl chitosan solution, and then add glycerin and CTAB. The glycerol concentration is 5wt% and the CTAB concentration is 0.1wt%. Stir for 1h. Then pour the mixed solution into a D160mm petri dish and place it at 30°C for 0.5h under vacuum and degassing. Place the defoamed solution at 50°C for 8h. Take out the dry petri dish and pour it into an excess alcohol coagulation bath for 0.5h. The decarboxylated chitosan wet film was dried at 30°C for 10 hours. Then, carboxymethyl chitosan can be obtained, and the film thickness is about 10 μm.

Embodiment 2

[0023] Take 0.3g of carboxymethyl chitosan and add it to 99.7ml of water to obtain a 0.3% carboxymethyl chitosan solution, and then add glycerin and CTAB. The glycerol concentration is 5wt% and the CTAB concentration is 0.1wt%. Stir for 1h. Then pour one-half of the mixed solution into a D160mm petri dish and place it at 30°C for 0.5h under vacuum and degassing. Place the defoamed solution at 50°C for 8h. Take out the dry petri dish and pour it into an excess alcohol coagulation bath for 0.5h. Place the removed carboxymethyl chitosan wet film at 30°C for 10 hours. The carboxymethyl chitosan film can be obtained, and the film thickness is about 5 μm.

Embodiment 3

[0025] Take 0.6g carboxymethyl chitosan and add it to 99.4ml water to obtain a 0.6% carboxymethyl chitosan solution, then add glycerin and CTAB, where the glycerol concentration is 5wt%, the CTAB concentration is 0.1wt%, strong Stir for 1h. Then pour the resulting mixed solution into a D160mm petri dish and place it at 30°C for 0.5h under vacuum and degassing. Place the defoamed solution at 50°C for 8h. Take out the dry petri dish and pour it into an excess alcohol coagulation bath for 0.5h. Place the removed carboxymethyl chitosan wet film at 30°C for 10 hours. Then, carboxymethyl chitosan can be obtained, and the film thickness is about 13 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com