Device and method for strengthening granulation process of aerobic sludge

An aerobic sludge and granulation technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc. The effect of high biomass, good sludge settling performance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

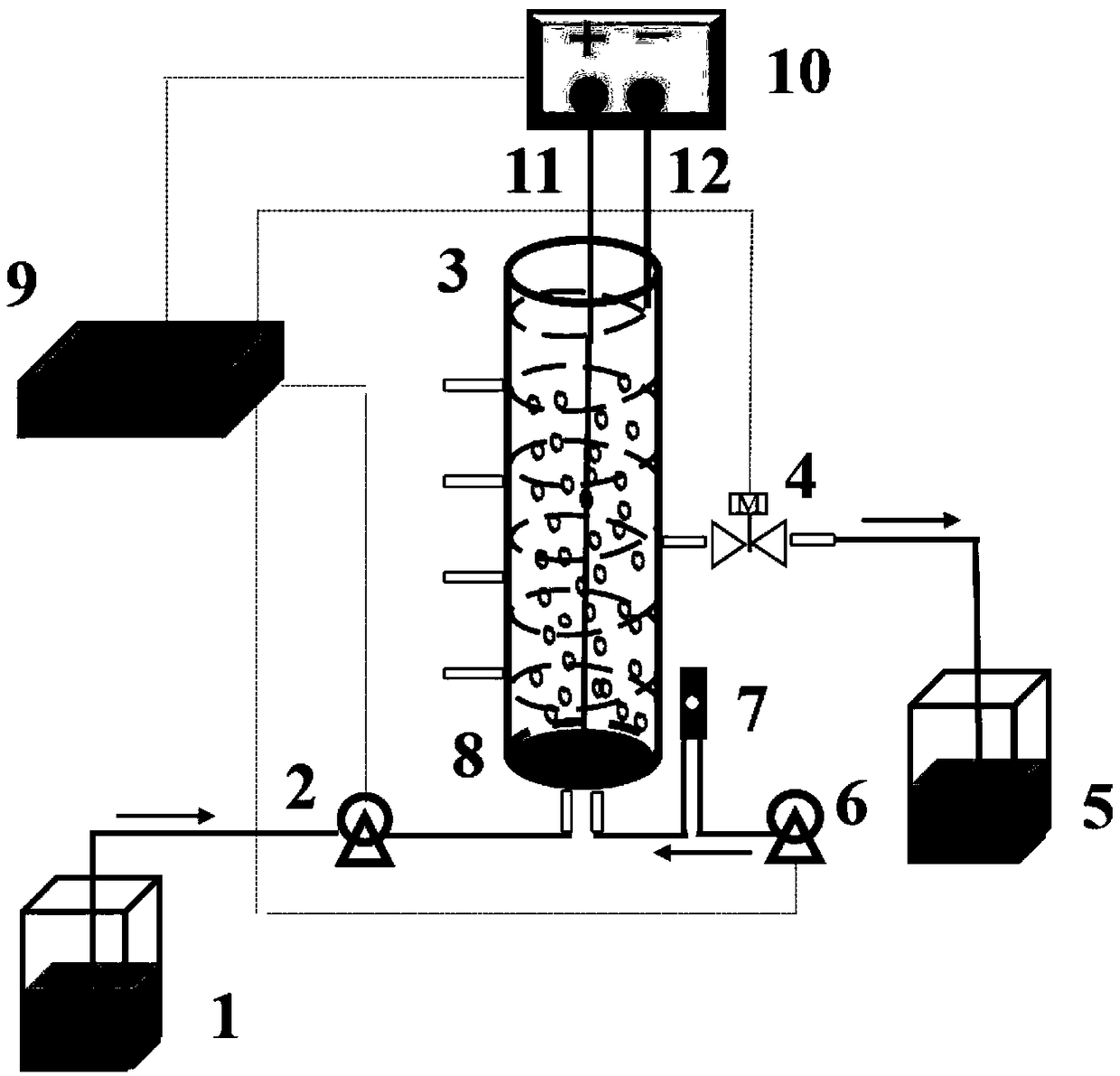

[0027] Specific implementation mode one: as figure 1 As shown, the device for strengthening the aerobic sludge granulation process provided by this embodiment includes a water inlet unit, a reactor 3, an aeration unit, a water outlet unit and a control unit 9, wherein:

[0028] The water inlet unit includes a water inlet tank 1 and a water inlet peristaltic pump 2 for controlling the water inlet flow and time, and the outlet pipe of the water inlet peristaltic pump 2 is connected with the water inlet at the bottom of the reactor 3;

[0029] The main body of the reactor 3 is a cylindrical sequential batch reactor, an inert titanium cathode 12 is arranged on the inner side of the cylinder wall, an active iron anode 11 is arranged in the center of the cylinder, and two electrodes of the inert titanium cathode 12 and the active iron anode 11 are arranged. The lead wire at the end of the terminal is connected with the DC stabilized voltage power supply 10;

[0030] The aeration un...

specific Embodiment approach 2

[0038] Embodiment 2: This embodiment provides a method for strengthening the aerobic sludge granulation process using the device described in Embodiment 1. The method includes the following steps:

[0039] Step 1. Influent water source configuration process: manually configure the influent water source to simulate urban domestic sewage, in which: COD is 300-800mg / L, NH4 + -N is 40~80mg / L, TP is 8~1510mg / L;

[0040] Step 2. Inoculation process: inoculate the domesticated flocculent sludge in the reactor so that the initial MLSS in the reactor is 3-6 g / L;

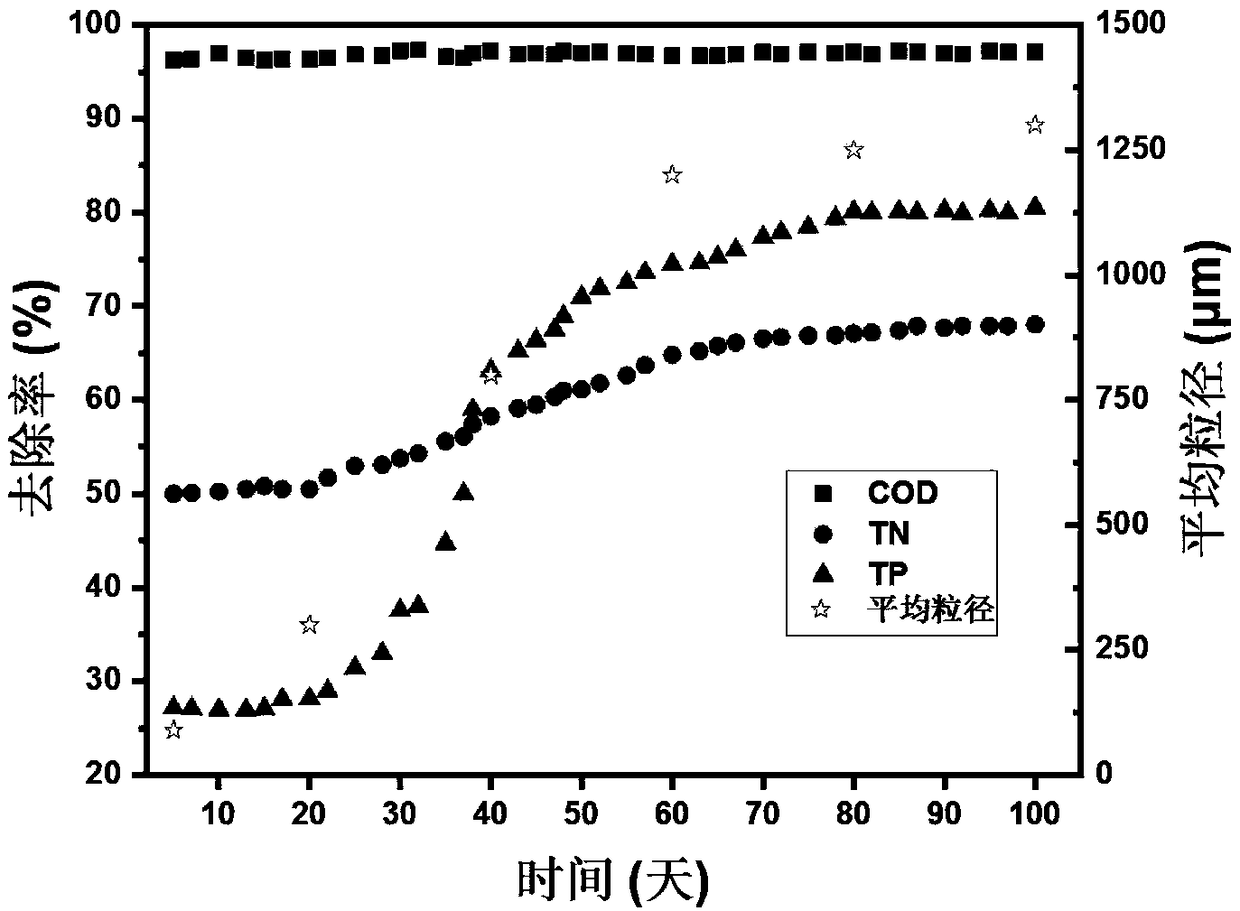

[0041] Step 3. Aerobic sludge granulation process: The reactor is operated by SBR process, and the operation period is 4-6 hours, which is divided into four stages: water inflow, aeration, sedimentation and drainage. Among them: the sedimentation time is 5-20 minutes, and the aeration The gas time is 210-225 minutes; constant voltage direct current is continuously applied to the aerobic granular sludge system during the oper...

specific Embodiment approach 3

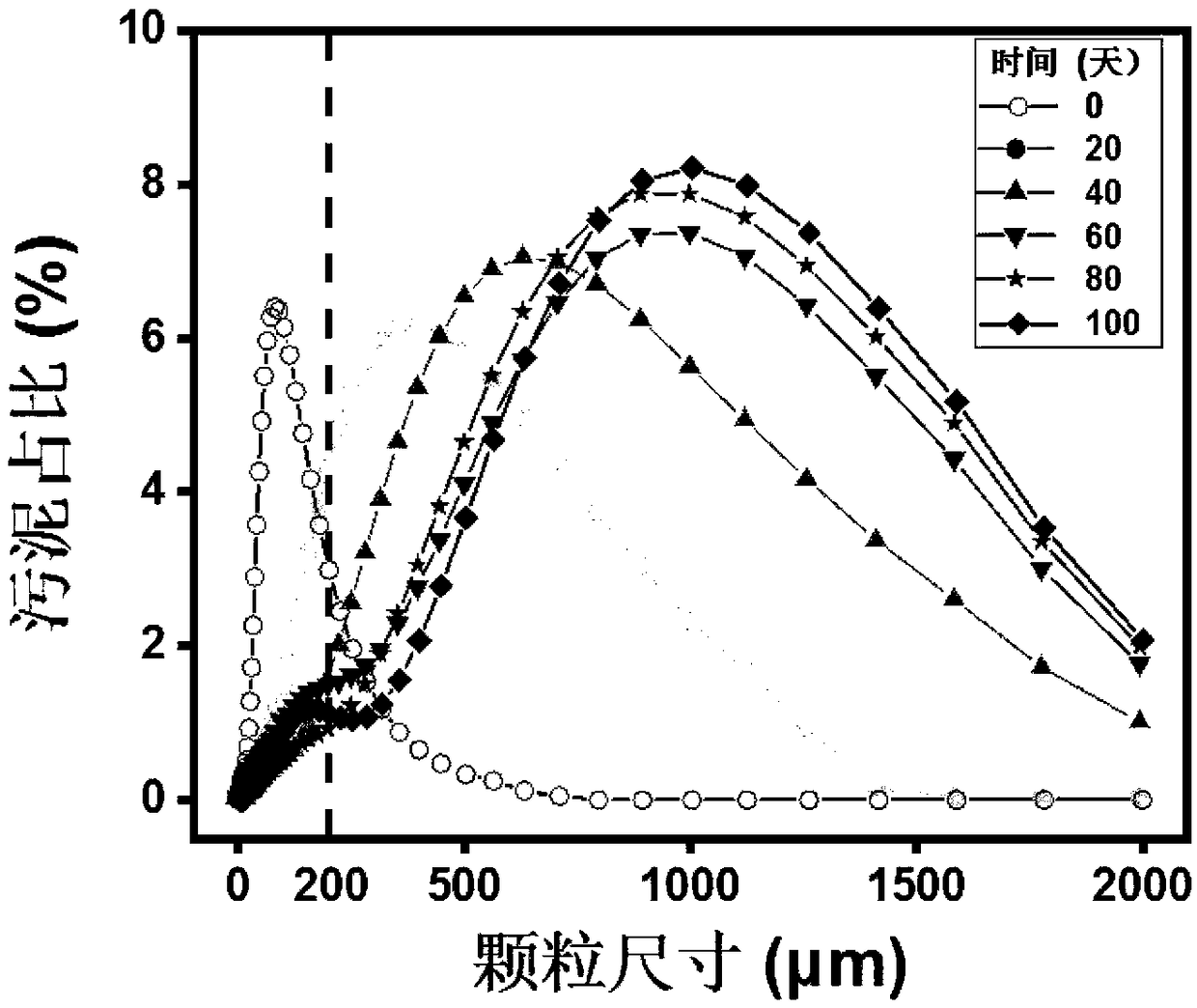

[0047] Specific implementation mode three: This implementation mode provides a method for strengthening the aerobic sludge granulation process, and the specific implementation steps of the method are as follows:

[0048] (1) Preparation of water source

[0049] The influent water source is simulated urban domestic sewage artificially configured in the laboratory, in which COD is 600mg / L, NH4 + -N is 60 mg / L, TP is 10 mg / L, and pH is 6.5. In addition, 0.5mM calcium and magnesium ions and 1mL / L trace element solution were added to the influent. Among them, 1L trace element solution contains: FeCl 3 ·6H 2 O, 1.5g; H 3 BO 3 , 0.15g; CuSO 4 ·5H 2 O, 0.03g; KI, 0.18g; MnCl 2 4H 2 O, 0.12g; Na 2 MoO 4 2H 2 O, 0.06g; ZnSO 4 ·7H 2 O, 0.12g; CoCl 2 ·6H 2 O, 0.15g; EDTA, 0.04g.

[0050] (2) Inoculate flocculent sludge

[0051] A certain amount of domesticated flocculent sludge is inoculated in the device of the present invention, so that the initial MLSS in the reactor ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com