Drum type high-efficiency energy-saving micro-electrolysis reactor

A micro-electrolysis reactor, high-efficiency and energy-saving technology, applied in chemical instruments and methods, special treatment targets, water/sewage treatment, etc., can solve problems such as difficulty in stirring and low efficiency of micro-electrolysis devices, and achieve continuous processing and energy saving. , to ensure the effect of safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

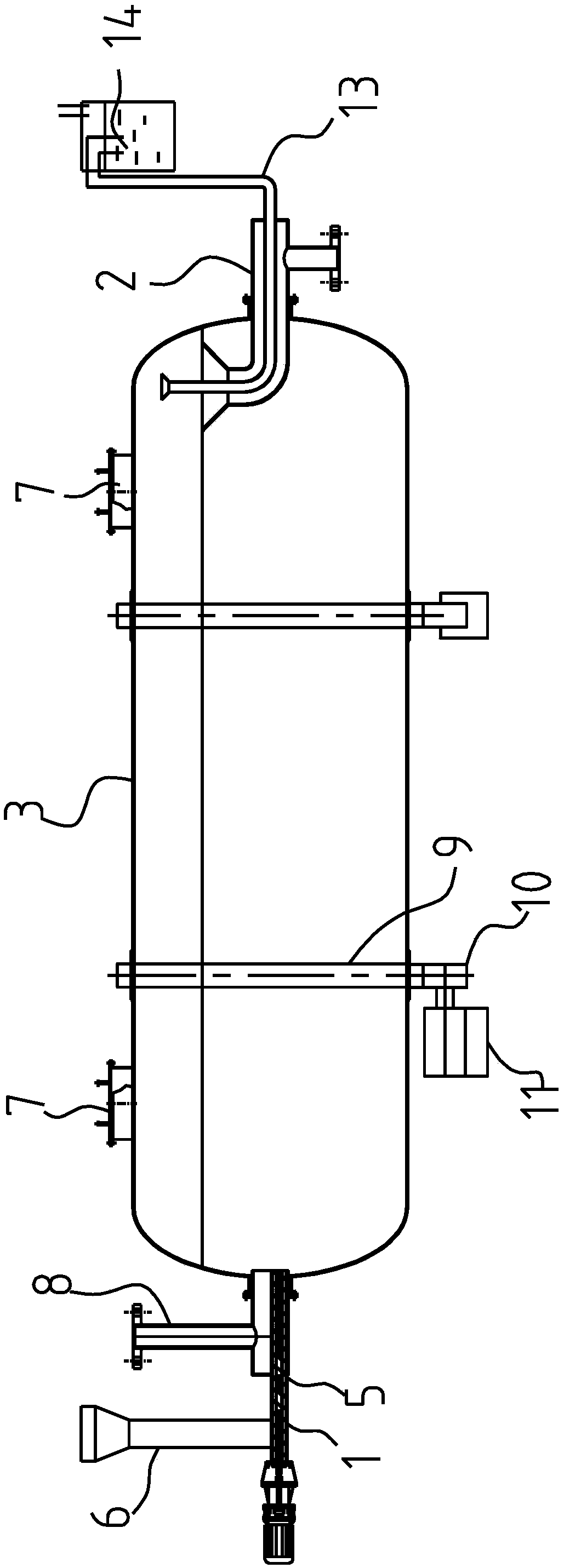

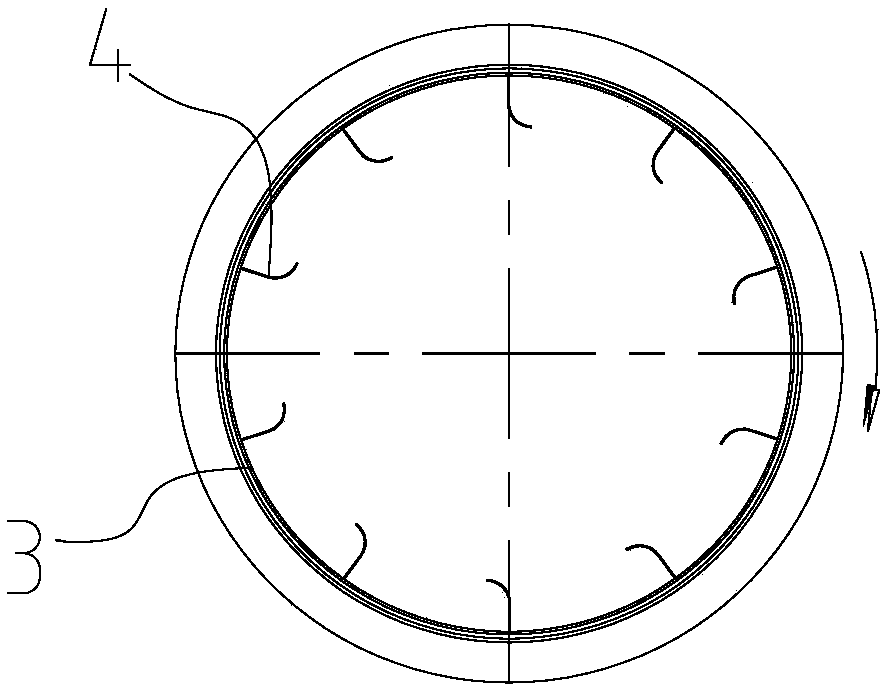

[0022] Such as Figure 1-2 , a drum-type high-efficiency energy-saving micro-electrolysis reactor, including a fixed feed pipe 1 and a discharge pipe 2, the feed pipe 1 and the discharge pipe 2 are rotatably connected with a cylinder 3, that is, the feed pipe 1 and the discharge pipe 2 The discharge pipe 2 does not move, and the cylinder body 3 rotates relative to the feed pipe 1 and the discharge pipe 2. A driving device for driving the cylinder body 3 to rotate is provided on one side of the cylinder body 3, and a flipper with one side opening is fixed on the inner wall of the cylinder body 3. The opening direction of the material plate 4 and the turning plate 4 is the same as the rotation direction of the cylinder body 3. The feeding pipe 1 is provided with a conveying screw 5, and above the conveying screw 5 is provided with the feeding pipe 1 for inputting iron powder and charcoal. The feeding pipe 6 of the powder, the feeding pipe 1 is connected with the waste water inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com