A method for preparing strontium niobate/strontium carbonate composite nanomaterial

A composite nanomaterial and nanomaterial technology, applied in the field of functional material preparation, can solve problems such as high solid-phase reaction temperature, and achieve the effects of improving efficiency, simple operation and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a method for preparing strontium niobate / strontium carbonate composite nanomaterial, comprising the following steps:

[0032] (1) 0.2g SnNb 2 o 6 Disperse the nanosheets in 10mL deionized water, add 0.9g potassium hydroxide and 0.2g strontium hydroxide to make a paste;

[0033] (2) With the pasty mixture that step (1) obtains as reaction precursor, in containing CO 2 (input is 0.2m 3 / h, from the beginning of heat treatment, maintain the airtight reactor (volume is 20mL) of importing 4h) and carry out heat treatment, temperature is 180 ℃, and the time is 24h, promptly obtains described strontium niobate / strontium carbonate (SrNb 2 o 6 / SrCO 3 ) composite nanomaterials.

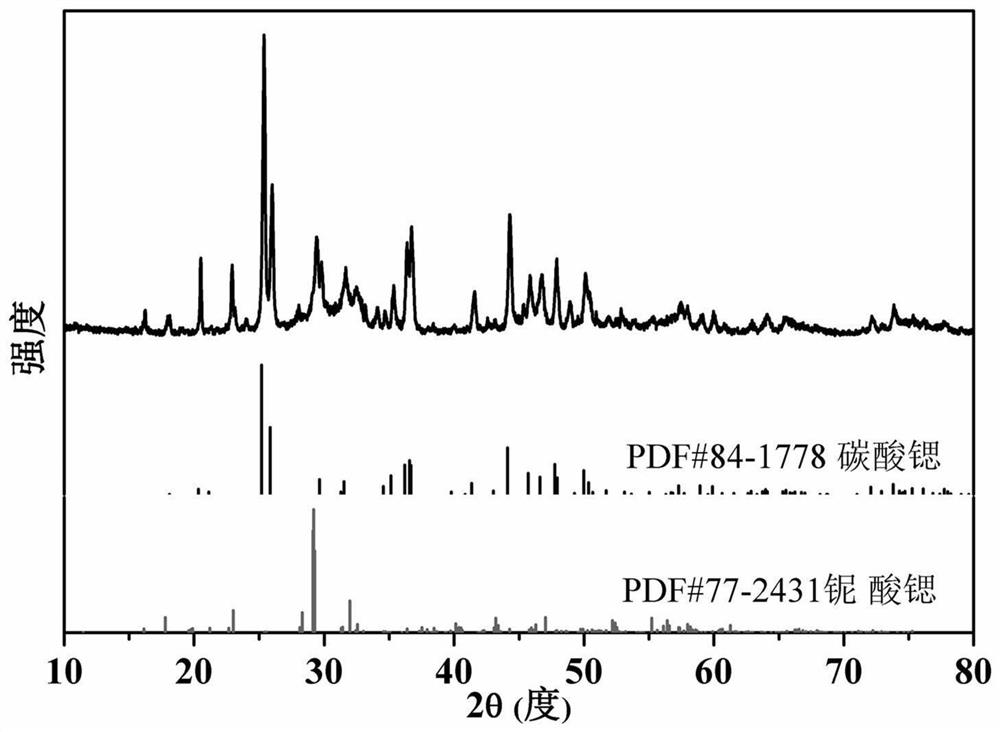

[0034] figure 1 For the SrNb prepared in this embodiment 2 o 6 / SrCO 3 X-ray diffraction patterns of composite nanomaterials.

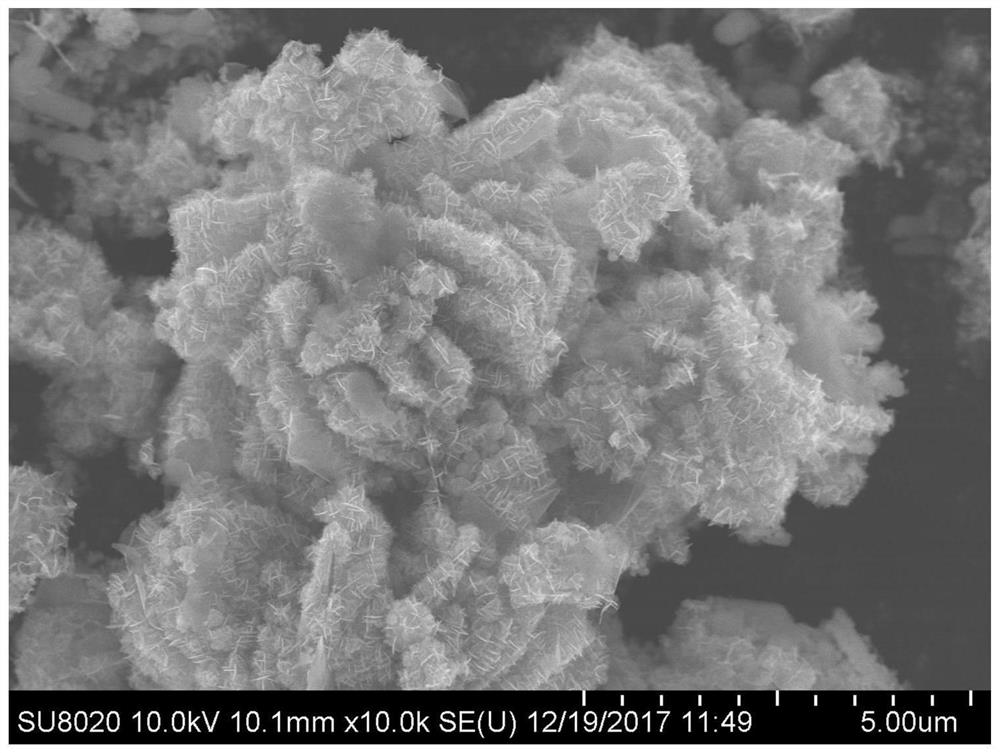

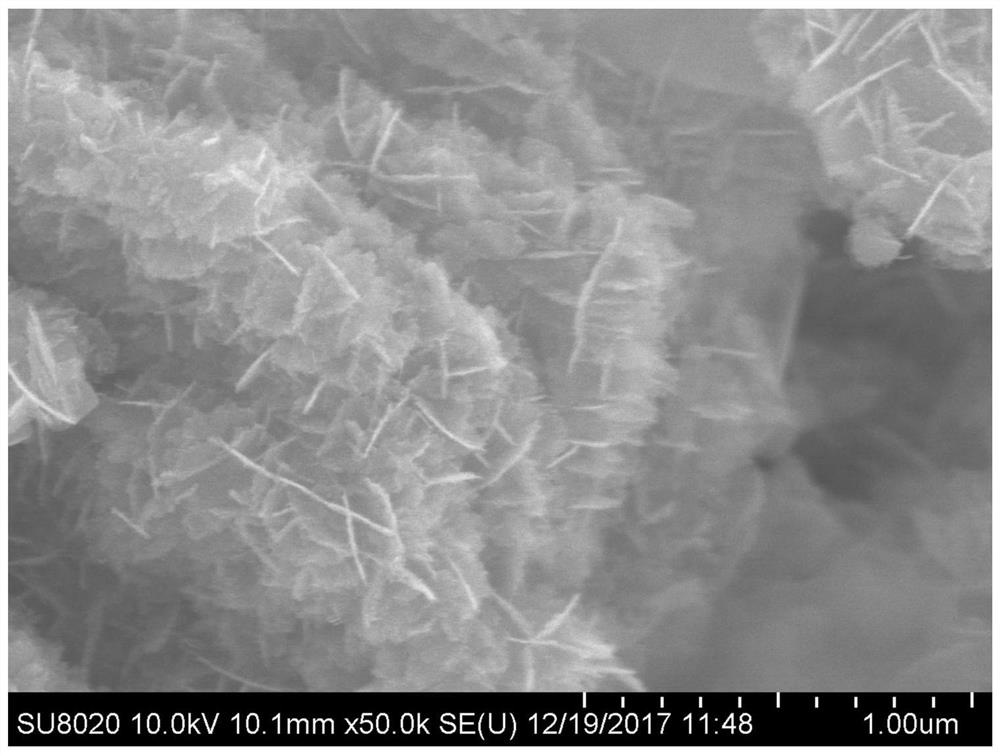

[0035] figure 2 and image 3 Respectively for the SrNb prepared in this example 2 o 6 / SrCO 3 Low-magnification and high-magnification...

Embodiment 2

[0038] This embodiment provides a method for preparing strontium niobate / strontium carbonate composite nanomaterial, comprising the following steps:

[0039] (1) 0.1g SnNb 2 o 6 Disperse the nanosheets in 10mL deionized water, add 0.4g potassium hydroxide and 0.8g strontium hydroxide to make a paste;

[0040] (2) With the pasty mixture that step (1) obtains as reaction precursor, in containing CO 2(input is 0.2m 3 / h, from the beginning of the heat treatment, maintain the heat treatment in the airtight reactor (volume is 20mL) of input 2h), the temperature is 200 ℃, and the time is 12h, promptly obtains described strontium niobate / strontium carbonate (SrNb 2 o 6 / SrCO 3 ) composite nanomaterials.

Embodiment 3

[0042] This embodiment provides a method for preparing strontium niobate / strontium carbonate composite nanomaterial, comprising the following steps:

[0043] (1) 0.2g SnNb 2 o 6 Disperse the nanosheets in 10mL deionized water, add 0.6g potassium hydroxide and 0.5g strontium hydroxide to make a paste;

[0044] (2) With the pasty mixture that step (1) obtains as reaction precursor, in containing CO 2 (input is 0.2m 3 / h, from the beginning of the heat treatment, maintain the heat treatment in the airtight reactor (capacity is 20mL) of input 1h), the temperature is 180 ℃, and the time is 12h, promptly obtains described strontium niobate / strontium carbonate (SrNb 2 o 6 / SrCO 3 ) composite nanomaterials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com