Preparation method of two-dimensional alumina powder

A technology of alumina powder and aluminum salt, applied in the field of preparation of two-dimensional alumina powder, can solve the problems of long preparation period, rough surface, irregular shape, etc., achieve uniform and controllable thickness of powder, overcome surface roughness, diameter Thickness ratio effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

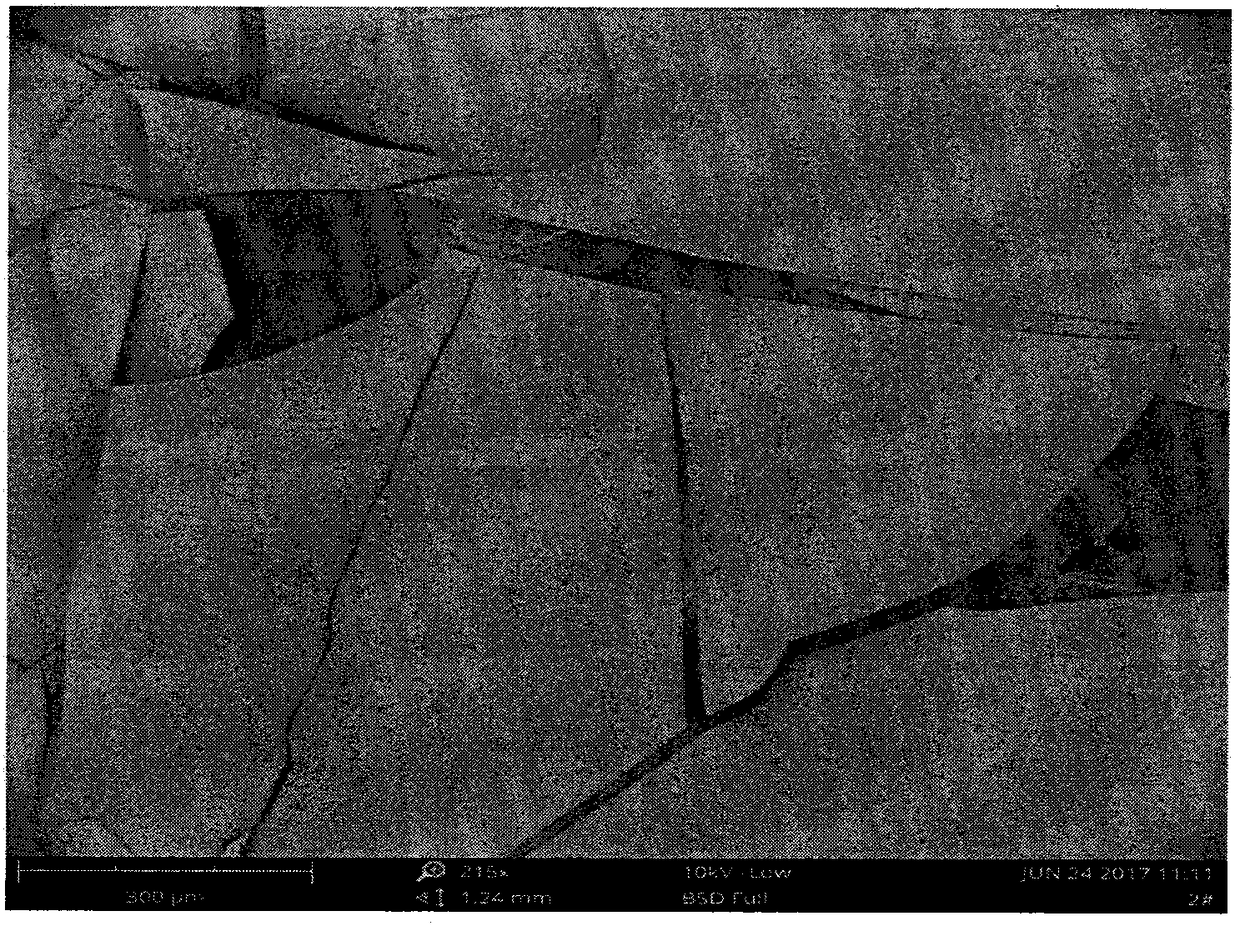

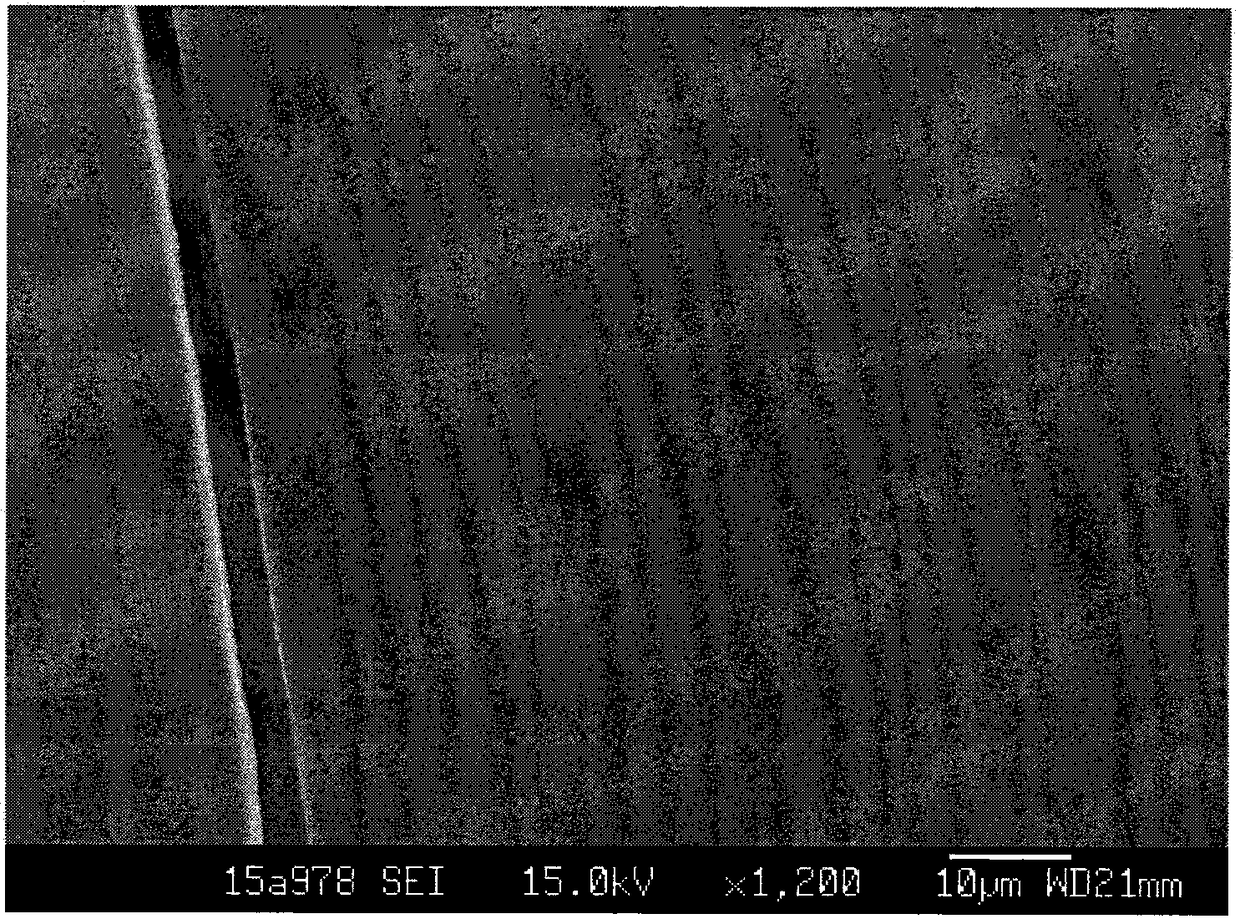

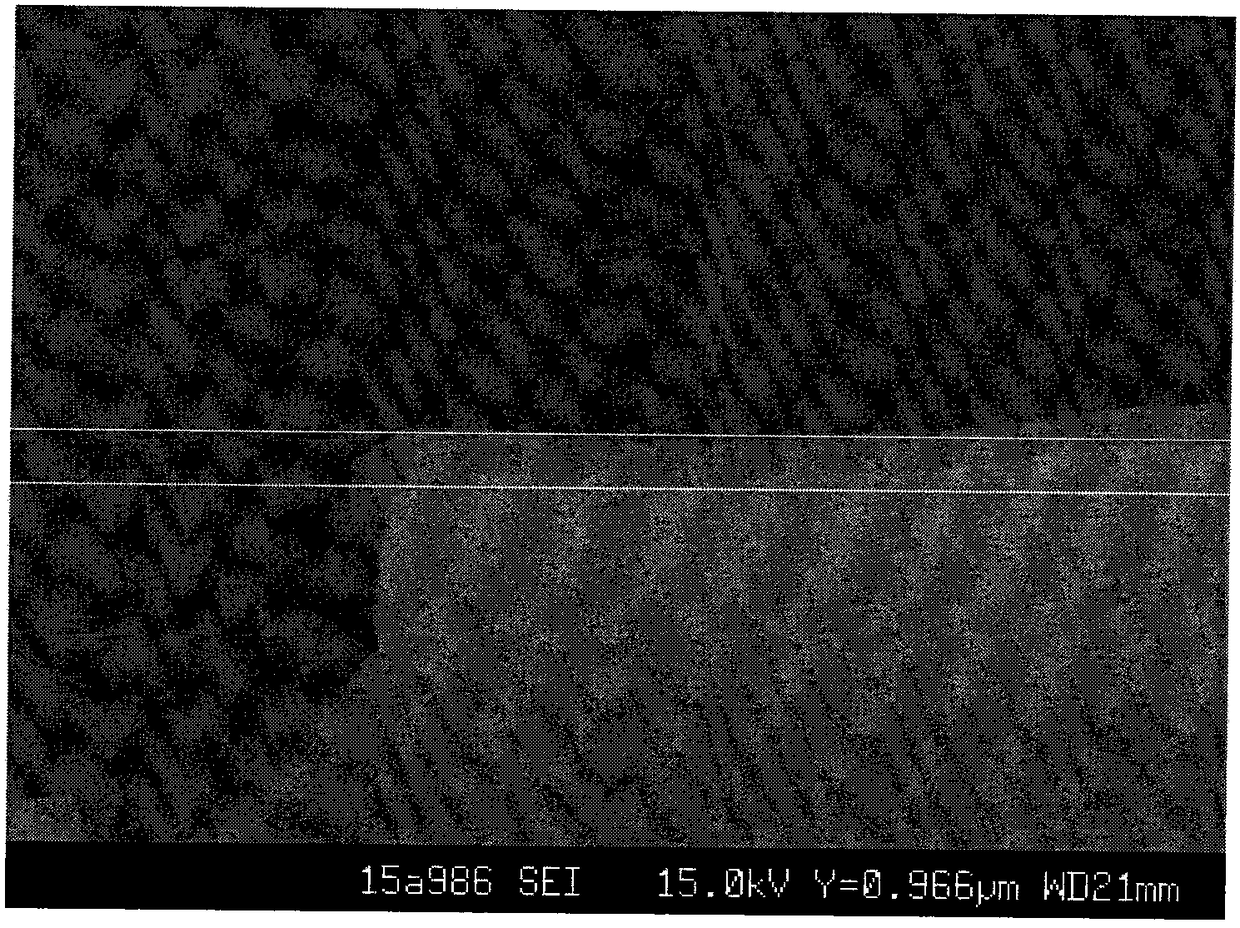

Image

Examples

Embodiment 1

[0025] 1. Select the molar ratio of acid to aluminum to be 0.17, and add a small amount of sodium lauryl sulfate as an additive to prepare aluminum sol. Using PET as the base, the steps for preparing two-dimensional alumina powder are as follows:

[0026] S1. Dissolve aluminum chloride hexahydrate in deionized water, and stir while adding ammonia water dropwise until the solution thickens and a white precipitate is formed;

[0027] S2. Wash and filter the white precipitate obtained in S1 to obtain a filter cake, add a certain amount of deionized water and concentrated nitric acid, stir evenly, transfer to a three-necked flask, add a small amount of sodium lauryl sulfate as an additive, and Under the conditions of temperature 90°C and stirring speed 500r / min, react for 11h to obtain a transparent aluminum sol;

[0028] S3. Soak the PET substrate in acetone for 30 minutes, rinse it with water, then place the substrate in 0.1mol / L sodium hydroxide solution, boil it in water at 80...

Embodiment 2

[0032] 2. Select the acid-aluminum molar ratio of 0.15 to prepare aluminum sol, use PET as the base, and modify the PET base with completely alcoholyzed polyvinyl alcohol PVA. The steps for preparing two-dimensional alumina powder are as follows:

[0033] S1. Dissolve aluminum chloride hexahydrate in deionized water, and stir while adding ammonia water dropwise until the solution thickens and a white precipitate is formed;

[0034] S2. Wash and filter the white precipitate obtained in S1 to obtain a filter cake, add a certain amount of deionized water and concentrated nitric acid, stir evenly, transfer to a three-necked flask, and react at a reaction temperature of 90°C and a stirring speed of 500r / min 11h obtains transparent aluminum sol;

[0035] S3. Soak the PET substrate in acetone for 30 minutes, rinse it with water, then place the substrate in 0.1mol / L sodium hydroxide solution, boil it in water at 80°C for 1 hour, rinse it with water, dry it, and then apply it with a 15...

Embodiment 3

[0039] 3. Select the acid-aluminum molar ratio of 0.15 to prepare aluminum sol, and use PI as the base to prepare two-dimensional alumina powder. The steps are as follows:

[0040] S1. Dissolve aluminum chloride hexahydrate in deionized water, and stir while adding ammonia water dropwise until the solution thickens and a white precipitate is formed;

[0041] S2. Wash and filter the white precipitate obtained in S1 to obtain a filter cake, add a certain amount of deionized water and concentrated nitric acid, stir evenly, transfer to a three-necked flask, and react at a reaction temperature of 90°C and a stirring speed of 500r / min 11h obtains transparent aluminum sol;

[0042] S3. Soak the PI substrate in acetone for 30 minutes, rinse with water, then place the substrate in 0.1mol / L sodium hydroxide solution, boil it in water at 80°C for 1 hour, rinse it with water, and dry it for later use;

[0043] S4. Evenly coat the aluminum sol obtained in S2 on the PI substrate obtained i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com