Hole position correcting method of automatic hole forming system

A correction method and automatic system technology, applied in the direction of automatic control devices, manufacturing tools, metal processing machinery parts, etc., can solve problems such as complex aerodynamic shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

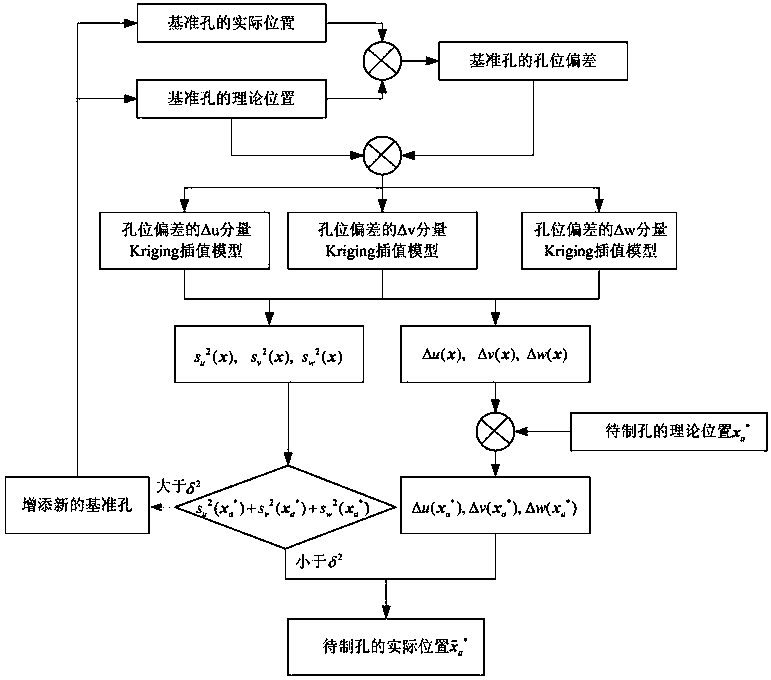

[0052] The hole position correction method of the automatic hole making system according to the present invention will be described in detail below with reference to the accompanying drawings.

[0053] The hole position correction method of the automatic hole making system according to the present invention includes steps S1-S8.

[0054] S1. Provide a workpiece to be drilled (such as a workpiece with complex aerodynamic shape and local weak stiffness deformation, and the workpiece is not limited to aircraft), and use computer-aided design software to establish a three-dimensional model of the workpiece to be drilled.

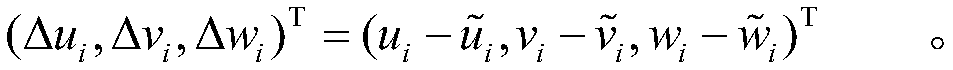

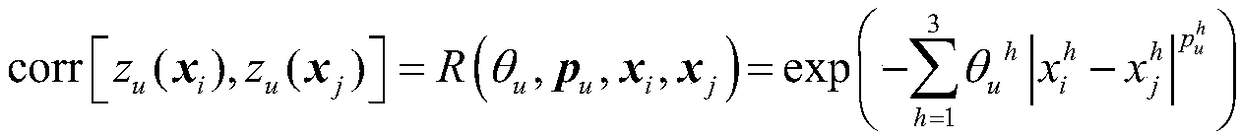

[0055] S2, construct a plurality of holes on the three-dimensional model, wherein the plurality of holes include N reference holes and M holes to be made, and mark the theoretical position x of the reference hole i =(u i ,v i ,w i ) T , i=1,2,...N (i represents the number of the reference hole), the theoretical positions x of the M holes to be made a * =(u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com