Mold shell and tool connecting method in spin force casting

A connection method and mold shell technology, applied in the field of investment casting, can solve the problems of difficult casting, poor metallurgical quality, loose castings, etc., and achieve the effect of reducing the use of steel, reducing the defects of casting inclusions, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with specific embodiments, but the embodiments of the present invention are not limited thereto. In the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other:

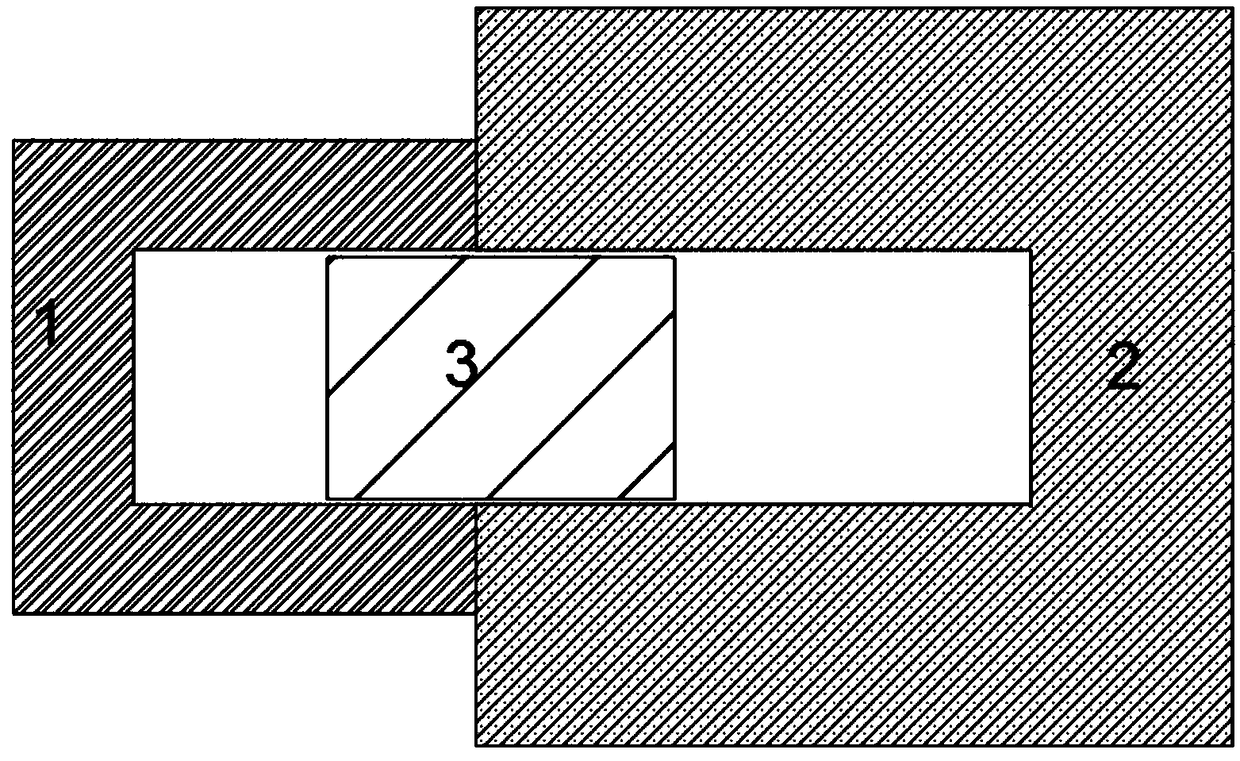

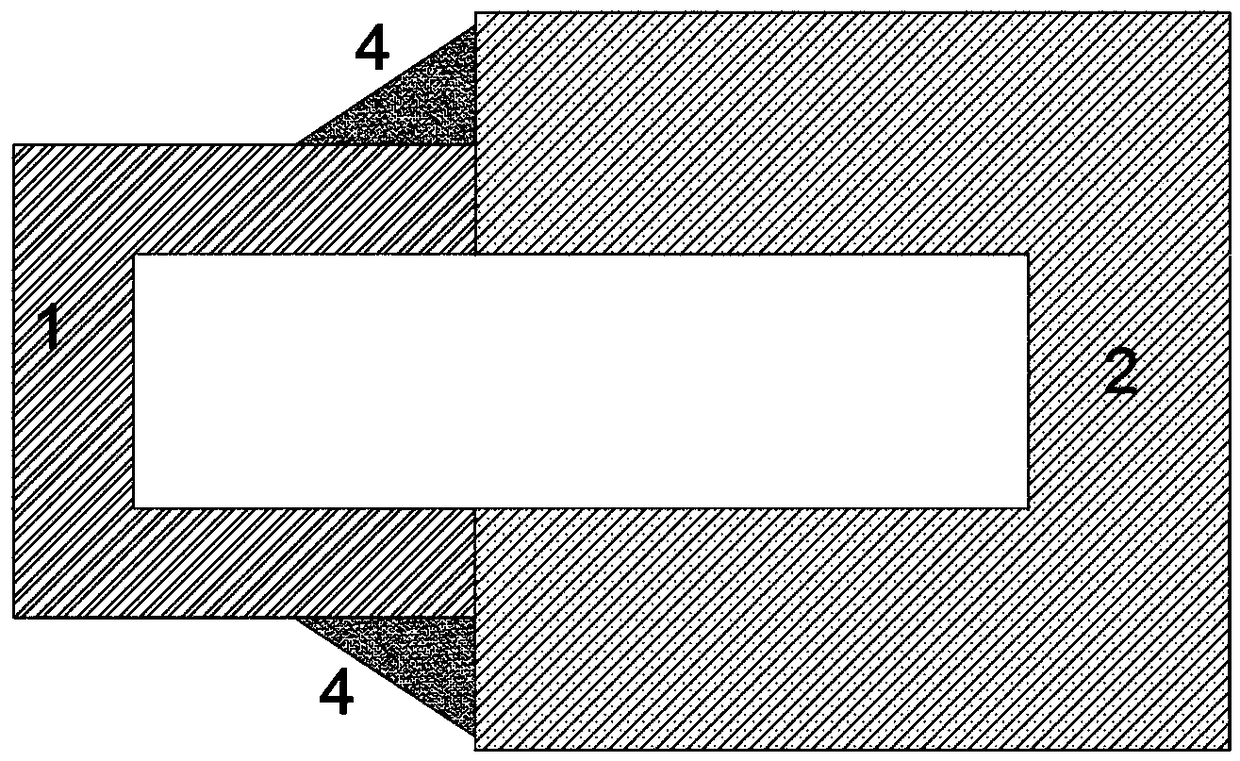

[0023] as attached figure 1 Among them, the combination of the casting formwork 1 and the pouring tool 2 needs to be connected through the tile tool in the middle. During the pouring process, the middle tile tool will produce impurities due to high temperature and affect the quality of the finished product.

[0024] A method for connecting mold shells and tooling in spin casting, characterized in that it includes mold shell shaping, assembly steps, adhesive preparation, seam patching, and mold group heating steps;

[0025] Among them, mold shell shaping: clean the mold shell to be poured and remove the flash;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com