Acrylic acid and sulfonated dihydroxypropyl chitosan modified polysulfone membrane and preparation method thereof

A technology of sulfonated dihydroxypropyl chitosan and branched sulfonated dihydroxypropyl shell, which is applied in the field of biomedical materials, can solve problems such as blood coagulation and protein adsorption, achieve improved hydrophilicity, simple preparation method, and maintain Effect of Mechanical Strength and Structural Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

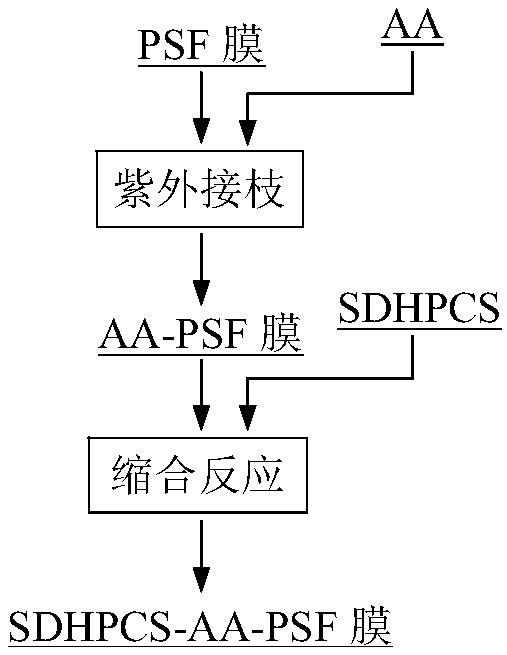

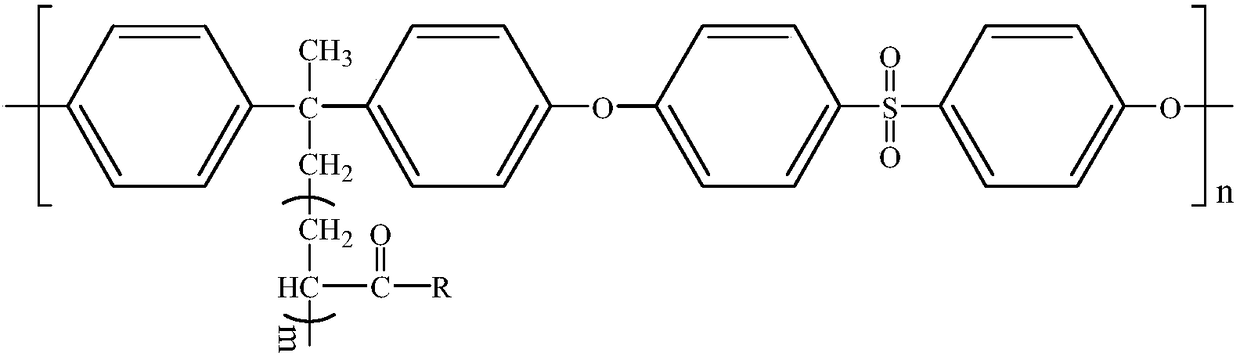

[0037] Add the polysulfone membrane (PSF membrane) to a mass concentration of 2% acrylic acid (AA) aqueous solution for 30 minutes; take out the polysulfone membrane or leave it in the original solution, and continue to irradiate it under a 160W ultraviolet lamp for 5 minutes. After taking it out, wash it with absolute ethanol and Wash with deionized water and dry in vacuum at 50°C to obtain AA-PSF membrane;

[0038] Add the above-mentioned AA-PSF membrane to 4°C, acetic acid buffer solution with a carbodiimide (EDC) concentration of 3mmoL / L for 4h to activate the carboxyl groups on the surface of the membrane; then wash with phosphate buffer and deionized water in sequence, Then add the activated membrane to 4°C, 0.1mg / mL SDHPCS acetic acid solution, stir for 20h; soak the obtained membrane in 2mmoL / L glutaraldehyde solution at 30°C for 60min, and then wash it with phosphate buffer saline Wash with deionized water, soak in deionized water for 12 hours, and dry in vacuum at re...

Embodiment 2

[0040] The polysulfone membrane (PSF membrane) was added to a mass concentration of 2% acrylic acid (AA) aqueous solution for 30 minutes; the polysulfone membrane was taken out or left in the original solution, and continuously irradiated under a 180W ultraviolet lamp for 10 minutes, and after taking it out, it was washed with absolute ethanol and Wash with deionized water and dry in vacuum at 50°C to obtain AA-PSF membrane;

[0041]Add the above-mentioned AA-PSF membrane to 4 ℃, acetic acid buffer solution with a carbodiimide (EDC) concentration of 3mmoL / L for 4h to activate the carboxyl groups on the surface of the membrane; then wash with phosphate buffer and deionized water in sequence, Then add the activated membrane to acetic acid solution of 0.2mg / mL SDHPCS at 4°C, and stir for 20h; soak the obtained membrane in 2mmoL / L glutaraldehyde solution at 30°C for 60min, and then rinse with phosphate buffer saline Wash with deionized water, soak in deionized water for 12 hours, ...

Embodiment 3

[0043] Add the polysulfone membrane (PSF membrane) into the aqueous solution of 3% acrylic acid (AA) for 30 minutes; take out the polysulfone membrane or leave it in the original solution, and continuously irradiate it under a 200W ultraviolet lamp for 8 minutes. Washed with deionized water and dried under vacuum at 50°C to obtain AA-PSF membrane;

[0044] Add the above-mentioned AA-PSF membrane to 4 ℃, acetic acid buffer solution with a carbodiimide (EDC) concentration of 3mmoL / L for 4h to activate the carboxyl groups on the surface of the membrane; then wash with phosphate buffer and deionized water in sequence, Then add the activated membrane to acetic acid solution of 0.2mg / mL SDHPCS at 4°C, and stir for 20h; soak the obtained membrane in 2mmoL / L glutaraldehyde solution at 30°C for 60min, and then rinse with phosphate buffer saline Wash with deionized water, soak in deionized water for 12 hours, and dry in vacuum at regular temperature to obtain SDHPCS-AA-PSF membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com