Anode catalytic material for direct borohydride fuel cell, anode material as well as preparation method and fuel cell

A fuel cell and borohydride technology, applied in fuel cells, nanotechnology for materials and surface science, battery electrodes, etc., can solve problems such as the complex combination of catalysts and basic electrodes, and achieve catalytic performance and discharge efficiency. Effect of reducing processing cost and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

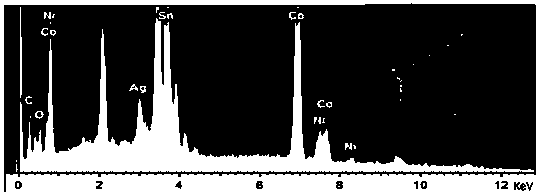

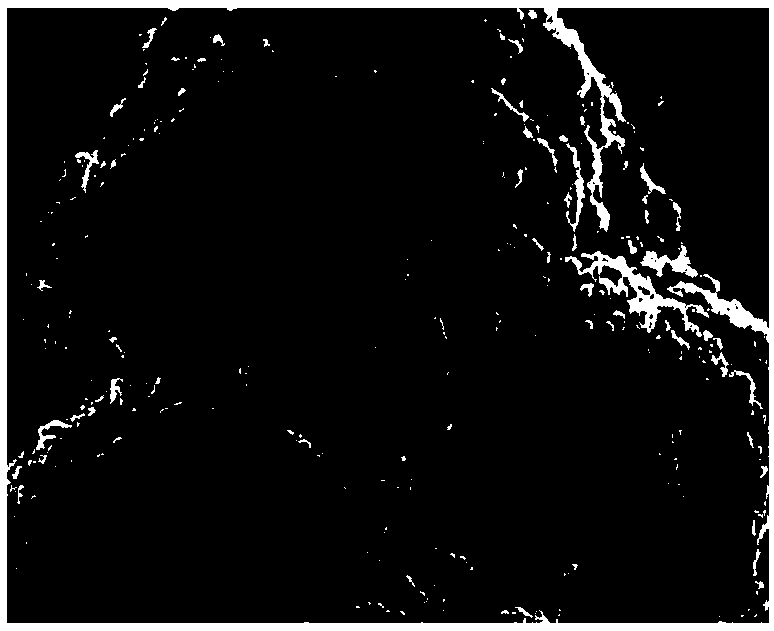

[0071] The anode catalyst material CoSn used for the direct borohydride fuel cell of the present embodiment 0.33 , The average particle size of the particles is 22nm.

[0072] The preparation method of the direct borohydride fuel cell anode material of the present embodiment:

[0073] Cut out nickel foam with an area of 2cm×2cm and ultrasonically clean it with absolute ethanol and 1mol / L hydrochloric acid for 15min. Rinse with deionized water and place in 0.4 wt% AgNO 3 The solution was subjected to photosensitization treatment at room temperature for 24 hours. It was then washed with deionized water and dried under vacuum at 50 °C for 12 h.

[0074] Accurately weigh 85mg SnSO 4 , 286mg CoSO 4 ·7H 2 O, 40mg Na 2 B 4 o 7 10H 2 O, 400mg NH 4 Cl and 1.22g KNaC 4 h 4 o 6 and dissolved in 20 mL of deionized water, and adjusted the pH value of the mixture to 12 with 1 mol / L NaOH solution.

[0075] Prepare 20mL 1mol / L NaOH solution and add 1.79g NaBH 4 . NaBH 4 Af...

Embodiment 2

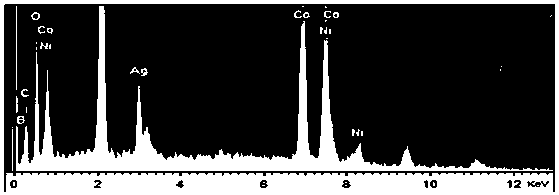

[0084] The anode catalyst material CoSn used for the direct borohydride fuel cell of the present embodiment 0.5 , The average particle size of the particles is 25nm.

[0085] The preparation method of the direct borohydride fuel cell anode material of the present embodiment:

[0086] Cut out nickel foam with an area of 2cm×2cm and ultrasonically clean it with absolute ethanol and 1mol / L hydrochloric acid for 15min. Rinse with deionized water and place in 0.4 wt% AgNO 3 The solution was subjected to photosensitization treatment at room temperature for 24 hours. It was then washed with deionized water and dried under vacuum at 50 °C for 12 h.

[0087] Accurately weigh 120mg SnSO 4 , 249mg CoSO 4 ·7H 2 O, 46 mg Na 2 B 4 o 7 10H 2 O, 410mg NH 4 Cl and 1.32g KNaC 4 h 4 o 6 and dissolved in 20 mL of deionized water, and adjusted the pH value of the mixture to 13 with 1 mol / L NaOH solution.

[0088] Prepare 20mL 1mol / L NaOH solution and add 1.79g NaBH 4 . NaBH 4 A...

Embodiment 3

[0091] The anode catalyst material CoSn used for the direct borohydride fuel cell of the present embodiment 0.9 , The average particle size of the particles is 18nm.

[0092] The preparation method of the direct borohydride fuel cell anode material of the present embodiment:

[0093] Cut out nickel foam with an area of 2cm×2cm and ultrasonically clean it with absolute ethanol and 1mol / L hydrochloric acid for 15min. Rinse with deionized water and place in 0.4 wt% AgNO 3 The solution was subjected to photosensitization treatment at room temperature for 24 hours. It was then washed with deionized water and dried under vacuum at 50 °C for 12 h.

[0094] Accurately weigh 186mg SnSO 4 , 191mg CoSO 4 ·7H 2 O, 44 mg Na 2 B 4 o 7 10H 2 O, 420mg NH 4 Cl and 1.32g KNaC 4 h 4 o 6 and dissolved in 20 mL of deionized water, and adjusted the pH value of the mixture to 13 with 1 mol / L NaOH solution.

[0095] Prepare 20mL 1mol / L NaOH solution and add 1.79g NaBH 4 . NaBH 4 A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com