Control method for forcible-discharge gas water heater

A gas water heater and control method technology, which is applied to fluid heaters, lighting and heating equipment, etc., can solve the problems of electric heating antifreeze failure, user losses, etc., and achieve the effects of preventing freeze cracking, safe use, and antifreeze effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

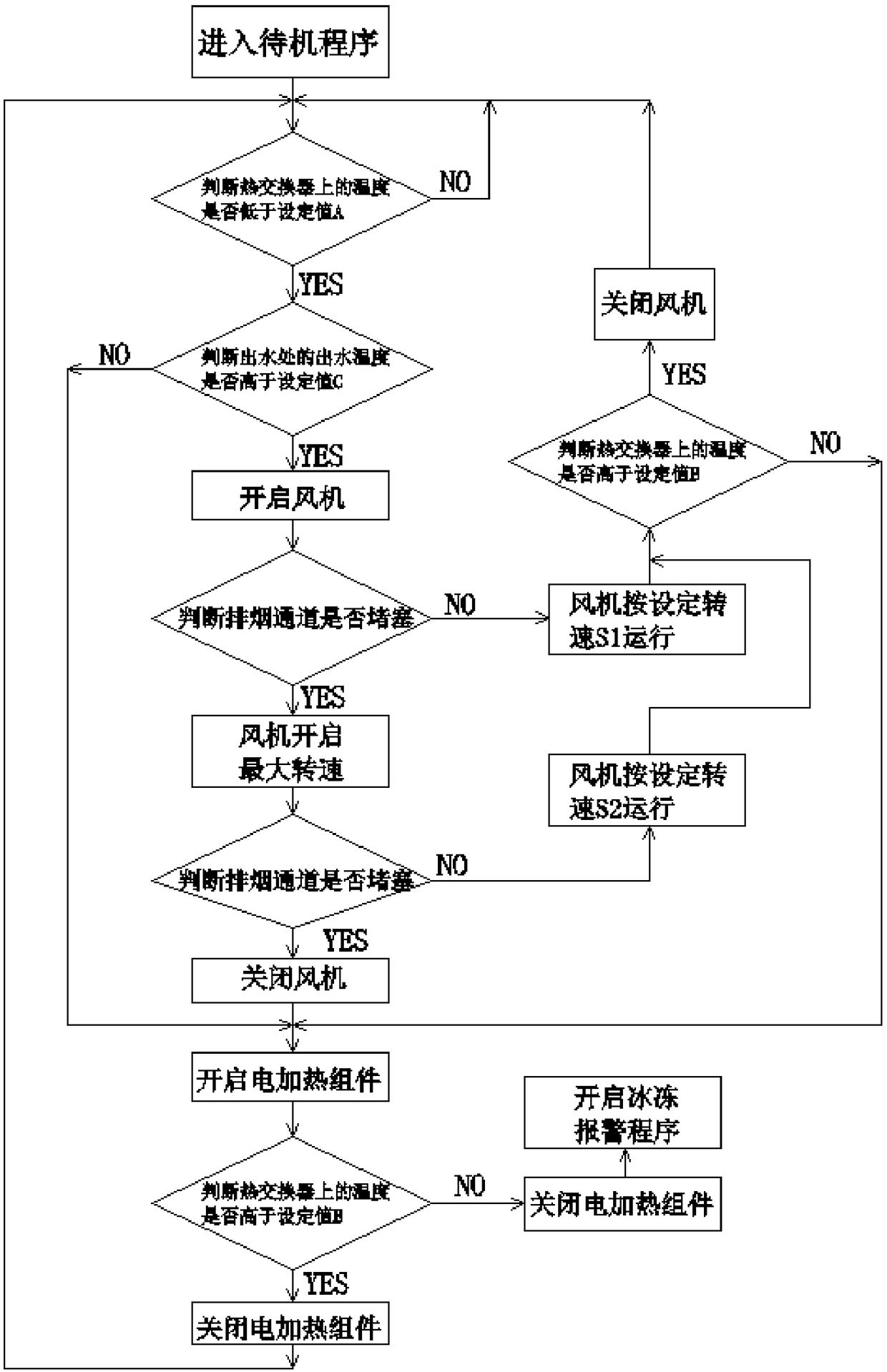

[0031] Such as figure 1 and image 3 As shown, after the gas water heater is powered on, the gas water heater enters the standby program, and the first temperature sensor and the second temperature sensor start to detect the temperature of the measured object respectively, and feed back the temperature data to the controller in real time;

[0032] When the first temperature sensor detects that the temperature on the heat exchanger is lower than the program setting value A, if the second temperature sensor detects that the outlet water temperature of the outlet pipe is higher than the program setting value C, the controller starts the fan and passes The fan speed sensor judges the blockage of the smoke exhaust channel:

[0033] Situation 1: When the controller judges that the smoke exhaust channel is not blocked according to the signal fed back by the fan speed sensor, the controller controls the fan to run at the set first speed S1. After the fan runs within the set time T1, ...

Embodiment 2

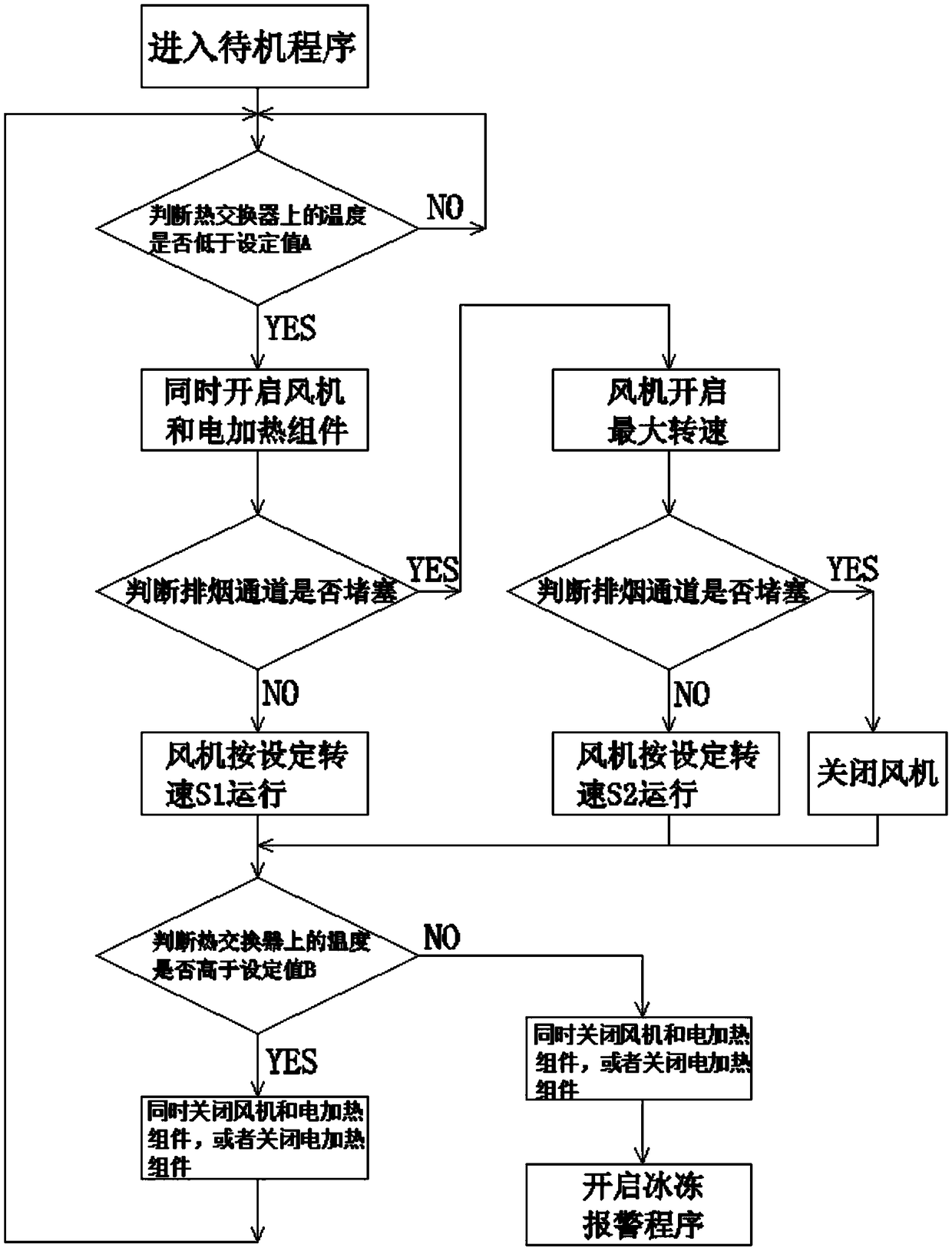

[0040] Such as figure 2 and image 3 As shown, after the gas water heater is powered on, the gas water heater enters the standby program, and the first temperature sensor starts to detect the temperature of the measured object, and feeds back the temperature data to the controller in real time;

[0041] When the first temperature sensor detects that the temperature on the heat exchanger is lower than the program setting value A, the controller starts the fan and the electric heating component at the same time, and judges the blockage of the smoke exhaust channel through the fan speed sensor:

[0042] Situation 1: When the controller judges that the smoke exhaust channel is not blocked according to the signal fed back by the fan speed sensor, the controller controls the fan to run at the set first speed S1. After the fan runs within the set time T1, if the first temperature When the sensor detects that the temperature on the heat exchanger is higher than the program setting v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com