Precision control system for aperture of large ball valve

A precise control, ball valve technology, applied in valve details, valve device, valve operation/release device, etc., to achieve the effect of easy control, accurate control of overcurrent flow, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

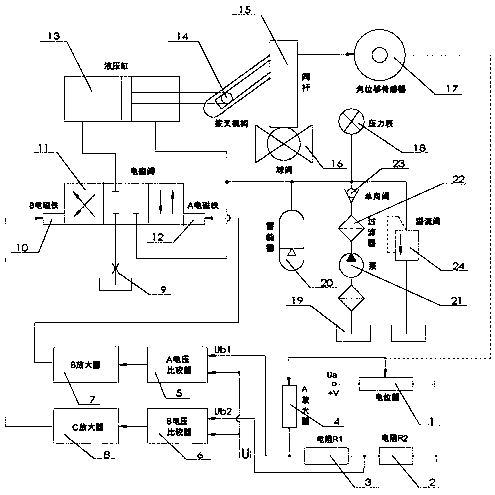

[0020] The following is attached figure 1 The present invention will be further explained.

[0021] This embodiment includes a potentiometer 1, an A amplifier 4, a three-position three-way solenoid valve 11, a hydraulic cylinder 13, a fork mechanism 14 and an angular displacement sensor 17.

[0022] One end of the potentiometer 1 is grounded, and the other end is connected to +V, which is used to detect the rotation angle of the valve stem 15 of the ball valve 16.

[0023] The input of the A amplifier 4 is the voltage U of the sliding contact of the potentiometer 1 a , A amplifier 4 output U b1 To the input terminal of A voltage comparator 5, the output of A amplifier 4 is through the resistance R 1 3. Resistance R 2 U generated by 2 partial pressure b2 To the input terminal of B voltage comparator 6. The other input terminal of the A voltage comparator and the other input terminal of the B voltage comparator are both connected to the command voltage U i , U i Is the command volta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com