Textile dyeing method and device

A fabric dyeing and dyeing device technology, applied in the field of dyeing, can solve the problems of dye migration on the cloth surface, consumption of large water resources, low heating efficiency, etc., and achieve the effects of rapid heating and cooling, strong penetration, and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

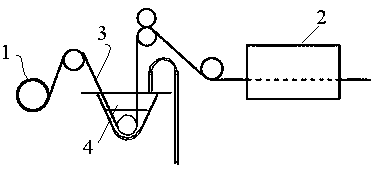

[0025] Such as figure 1 Shown, the embodiment of a kind of fabric dyeing method of the present invention comprises the steps:

[0026] 1) Dyeing: pass the fabric 3 through the paddle 1 to complete the dye / pigment adsorption process;

[0027] 2) Color fixation by electromagnetic wave heating: put the colored fabric 3 in the step 1) into the electromagnetic wave heating device 2 to heat, and after a period of time, the dye / pigment diffusion and fixation process on the fabric 3 is completed.

[0028] After step 2) is completed, proceed to step 3), that is, turn on the electromagnetic wave heating device, take out the color-fixed fabric 3, and clean or soap the color-fixed fabric 3.

[0029] Further specifically, the dyeing in step 1) adopts immersion or sizing, and the specific steps include: configuring the required dyeing precursor or coating slurry according to the material of the fabric, in order to complete the uniform adhesion in the fabric, after dyeing Add corresponding...

Embodiment 1

[0035] Embodiment 1: pure cotton fabric is dyed

[0036] 1) Prepare the dyeing precursor solution. Since the dyeing of cotton needs to be in an alkaline environment and the color can be fixed under the action of salt, it is necessary to add an appropriate amount of salt and alkali when configuring the precursor solution.

[0037] 2) Dyeing: After the cotton fabric 3 to be dyed is flattened by the screw, it passes through the prepared dyeing precursor solution 4 at a constant speed, and is colored by the paddle 1 to complete the fabric coloring process.

[0038] 3) Color fixing process: the cotton fabric 3 after coloring by the padder is directly transported to the electromagnetic wave heating device 2, and the curing time is adjusted for 5 minutes to achieve the best curing effect.

Embodiment 2

[0039] Embodiment 2: dyeing polyester fabric

[0040]1) Dissolve an appropriate amount of disperse dye in water according to the process requirements, and add an appropriate amount of thickener in the water to increase the adsorption of the dye precursor solution to polyester yarn. Let the polyester fabric pass through the pre-prepared dyeing precursor solution at a constant speed, and then pass through the rollers of the padding car 1 and squeeze it through the extrusion wheel, and adjust the pressure of the extrusion wheel to 0.1MPa to dye;

[0041] 2) Send the dyed polyester fabric to the electromagnetic wave heating device 2, and adjust the color fixing time to 3 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com