A biochemical sewage treatment process

A sewage treatment and biochemical treatment pool technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problem that the effluent cannot meet the effluent requirements, and achieve the stabilization of activated sludge The effect of strengthening and improving the reflux circulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

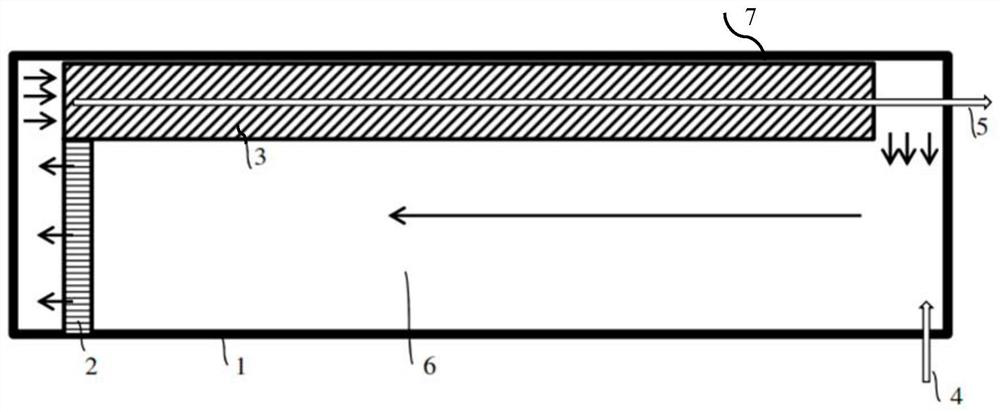

specific Embodiment example 1

[0042] Concrete implementation example 1, the present invention provides a kind of biochemical sewage treatment process, and its realization method comprises the following steps: (1) sewage is through pretreatment (grid, grit chamber), removes larger suspended matter and grit, then enters this The unit described in the invention—the biochemical pool, the influent water quality requirement TCOD: TN>4; (2) In the biochemical pool, the concentration of activated sludge is 8000 mg / L, and the sewage degrades COD, ammonia nitrogen, Nitrate nitrogen, the effluent in the final clarification area meets the requirements of surface water type IV water body, COD3 , the treated water volume is 8000m 3 / d, where the main aeration zone is 70m x 8m x 6m (length x width x height), the clarification zone is 70m x 4m x5m (length x width x height), and the sludge stabilization zone (channel) is below the clarification zone. Located on one side of the clarification zone, the size of the airlift zo...

specific Embodiment example 2

[0043] Concrete implementation case 2, the present invention provides a kind of biochemical sewage treatment process, and its realization mode comprises the following steps: (1) water intake 100m 3 / d, due to the large fluctuation of water inflow in the morning, noon and evening every day, a regulating pool of 40m is installed 3 , the residence time of the regulating pond is 10 hours, which is used to balance the water volume and water quality, and at the same time, the larger particles and sediment in the regulating pond are separated, and the cleaning period of the regulating pond is 3 years; (2) The regulating pond is equipped with a submersible pump Q=4m 3 / h, head 15m, evenly enters the biochemical treatment pool, and the effluent meets the requirements of the fourth category of surface water, that is, COD<20mg / L, TN<1.5mg / L; (3) The biochemical treatment pool is 12m long and is divided into two parts in the width range There are two main units: the main aeration area and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com