Start-up method of low-temperature groundwater biological iron and manganese removal process coupled with autotrophic denitrification

An autotrophic denitrification and groundwater technology, applied in the treatment of polluted groundwater/leachate, water pollutants, chemical instruments and methods, etc. problems, to achieve the effect of prolonging the backwash cycle, promoting the thickening of the biofilm, and promoting the secondary proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A start-up field test of a low-temperature groundwater biological iron and manganese removal process coupled with autotrophic denitrification was carried out in a filter tank newly put into use in a water plant. The plane size of the filter is 8m×5m, and the filter is filled with pebbles 35cm thick, particle size gradation 1.2-20mm, and manganese sand filter material 160cm thick, particle size gradation 0.6-1.2mm. Take the concentration as 2.8×10 8 CFU / ml ferromanganese oxidizing bacteria high-efficiency bacterial liquid, the concentration is 2.4×10 8 CFU / ml of high-efficiency nitrifying bacteria liquid and concentration is 2.5×10 8 CFU / ml high-efficiency anammox bacteria liquid, mix according to the volume ratio of 1:1:1 and mix evenly, measure 64L of mixed bacterial liquid and put it into the filter with the water. Feed the artificially prepared raw water into the filter, and circulate the culture at a filtration rate of 0.5m / h. The quality of the influent water is:...

Embodiment 2

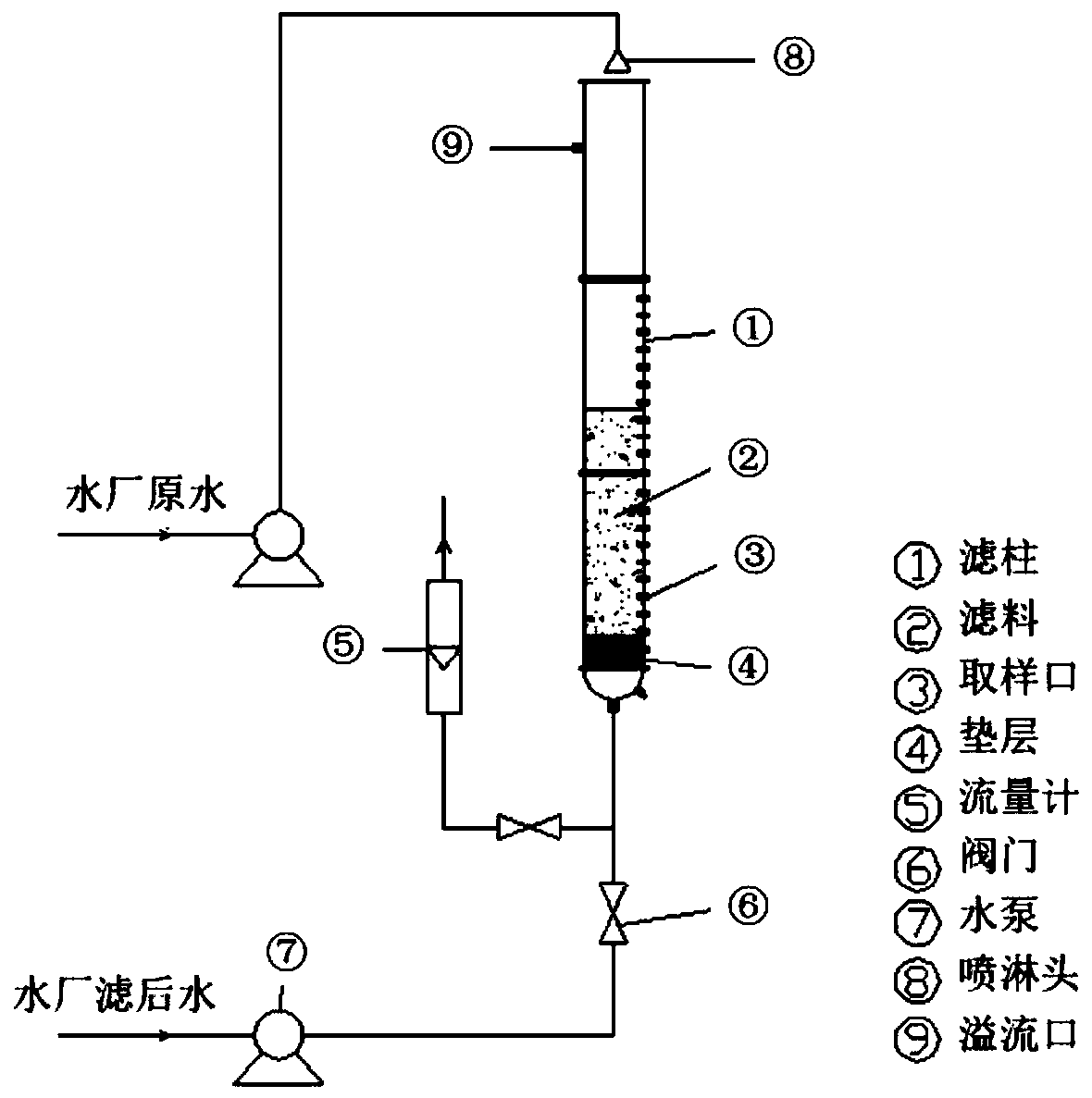

[0028] For the perennial low-temperature groundwater with 10-13 mg / L of total iron, 7-8.5 mg / L of ferrous iron, 1.2-1.5 mg / L of manganese, and 1.5-2.0 mg / L of ammonia nitrogen, there is only low-temperature groundwater at 5.0-5.8 °C all year round. The simulated filter column test reactor was used to carry out the start-up field test of the low-temperature groundwater biological iron and manganese removal process coupled with autotrophic denitrification. The simulated filter column reactor is 300cm high, with an inner diameter of 25cm. The simulated filter column reactor is laid with anthracite filter layer 40cm thick, particle size gradation 1.0-1.5mm, and quartz sand filter layer 120cm thick, particle size gradation 0.6~ 1.2mm, cobblestone cushion 35cm thick, particle size gradation 1.2-20mm, backwash water distribution system. Inoculate 78.5ml of mixed bacterial solution of iron-manganese oxidizing bacteria, nitrifying bacteria and anammox bacteria with a volume ratio of 1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com