Computer-vision-based self-adaptive control method for belt conveyor for coal wharf

A belt conveyor and computer vision technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as economic loss, safety accidents, high cost, and large number of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

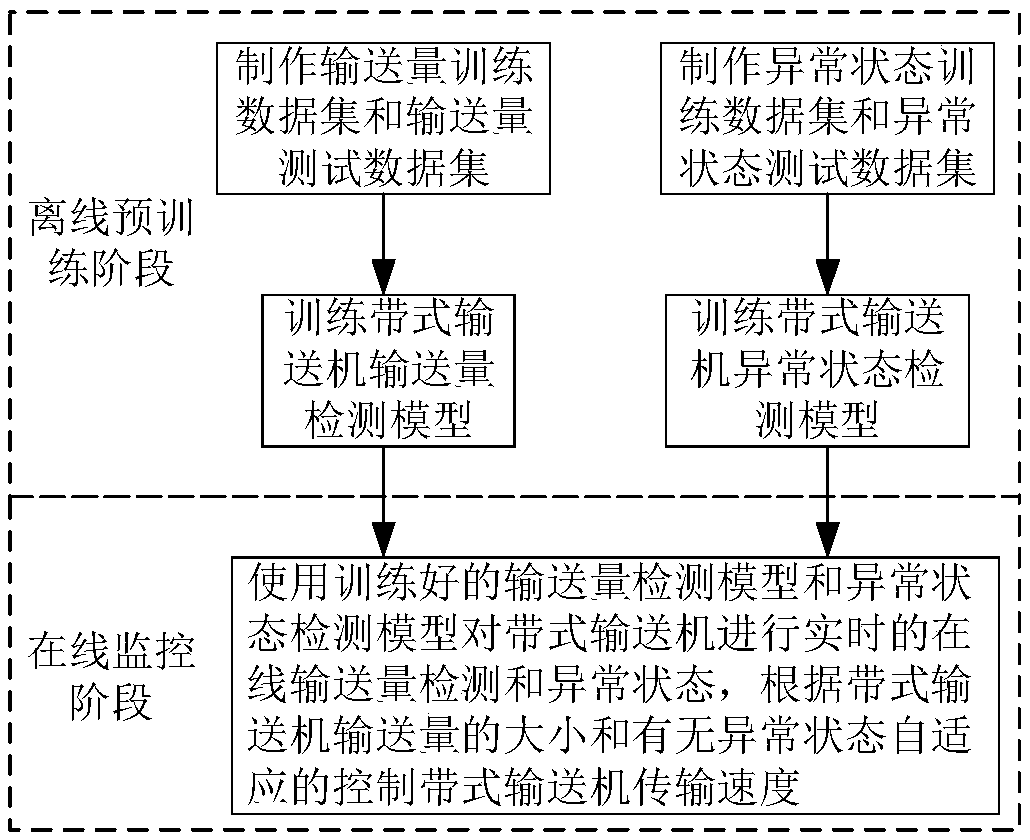

[0061] Such as figure 1 As shown, the overall process of the adaptive control method of the coal terminal belt conveyor based on computer vision is as follows:

[0062] The method includes an off-line pre-training stage and an online monitoring stage: the off-line pre-training stage includes making a delivery amount training data set and a delivery amount test data set, training a belt conveyor delivery amount detection model, making an abnormal training data set and Abnormal state test data set, training belt conveyor abnormal state detection model; the function of the online monitoring stage is to use the trained conveying capacity detection model and abnormal state detection model to carry out real-time online conveying capacity detection and abnormal State detection, adaptively control the transmission speed of the belt conveyor according to the size of the conveying volume of the belt conveyor and whether there is an abnormal state;

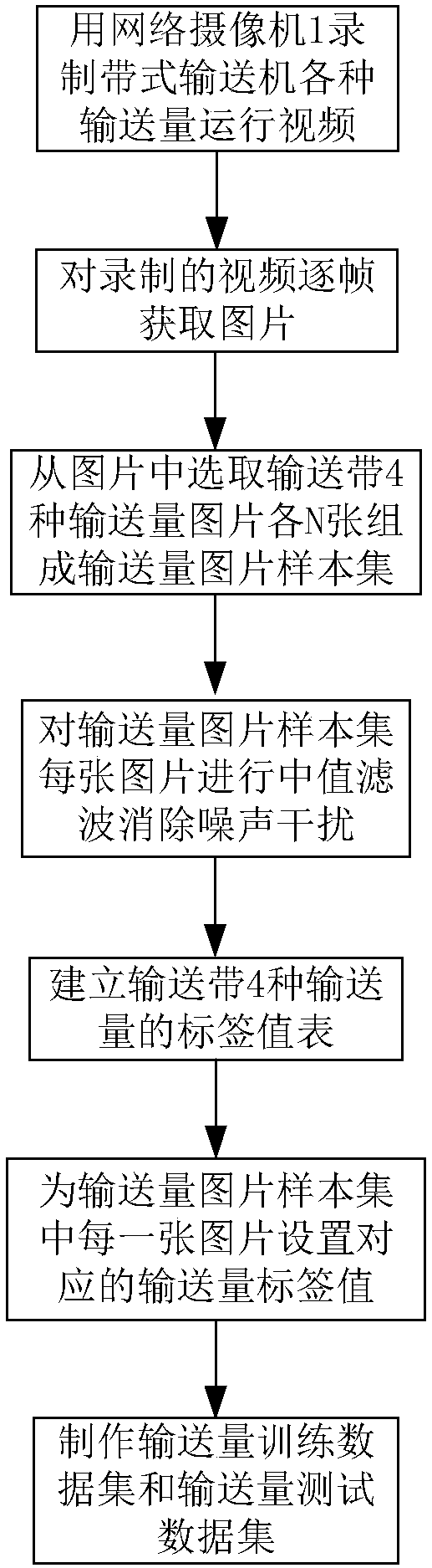

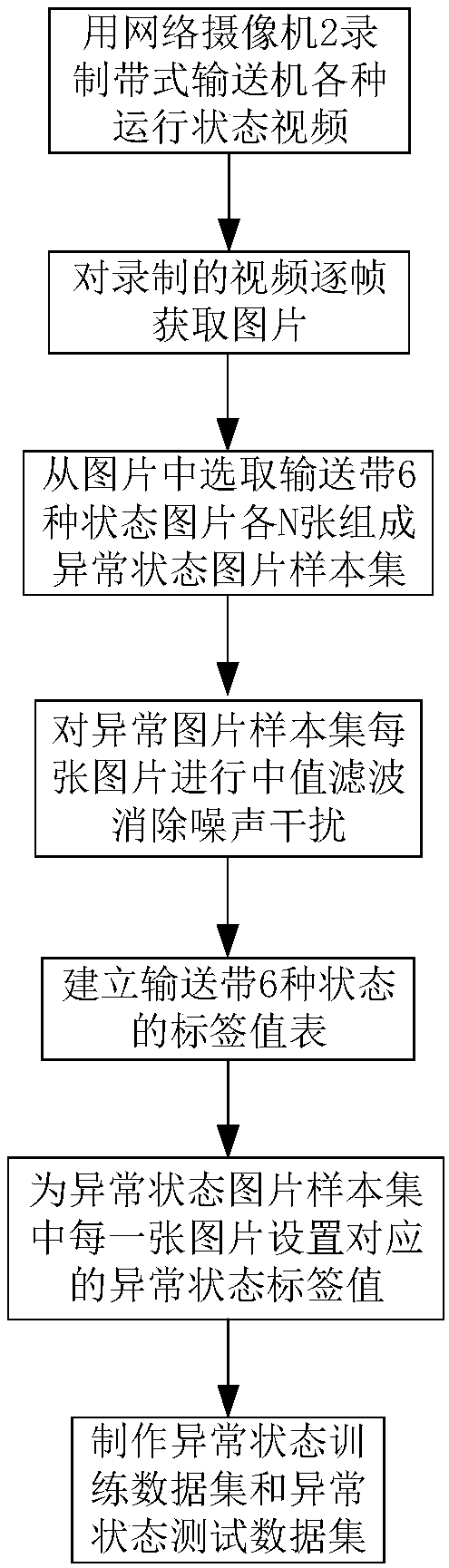

[0063] Such as figure 2 Shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com