High-strength packaging woven bag

A packaging woven bag, high-strength technology, applied in the field of packaging woven bags, can solve the problems of reduced crop yield, short service life, easy caking, etc., to prevent moisture intrusion and improve printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

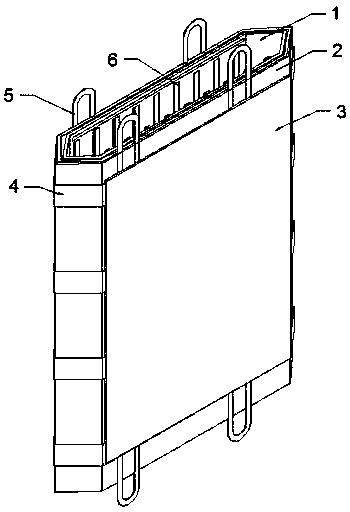

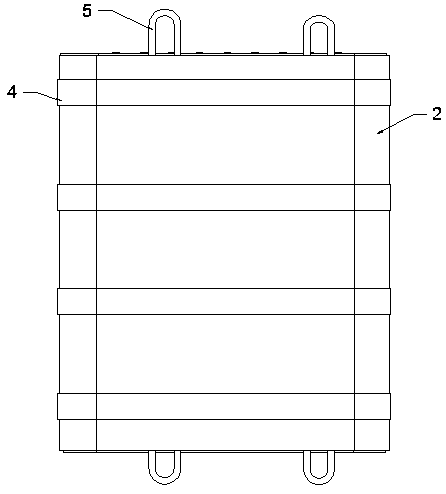

[0020] Such as Figure 1-2 As shown, a high-strength packaging woven bag includes a bag body 2, and the inner upper end of the opening of the bag body 2 is bonded with a liner 1 through a hot pressing process to improve the gap between the liner 1 and the bag body 2. The connection strength and smoothness of the connection. The material of the bag body 2 is woven from reinforced polypropylene fiber. This design can significantly improve the fertilizer carrying quality of the bag body 2, and can effectively prolong the service life of the bag body 2, so that the bag body 2 can be repeated Therefore, this design makes the bag body 2 more energy-saving and environment-friendly.

[0021] The outside of the bag body 2 is longitudinally bonded with a hand strap 5 by means of heat and pressure. The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com