Aircraft brake wheel cylinder seat damper

A damper and cylinder block technology, which is applied in the field of cylinder block dampers, can solve the problems of long development cycle and large waste of cylinder block components, and achieve the effects of reducing development costs, easy adjustment, and shortening the development cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

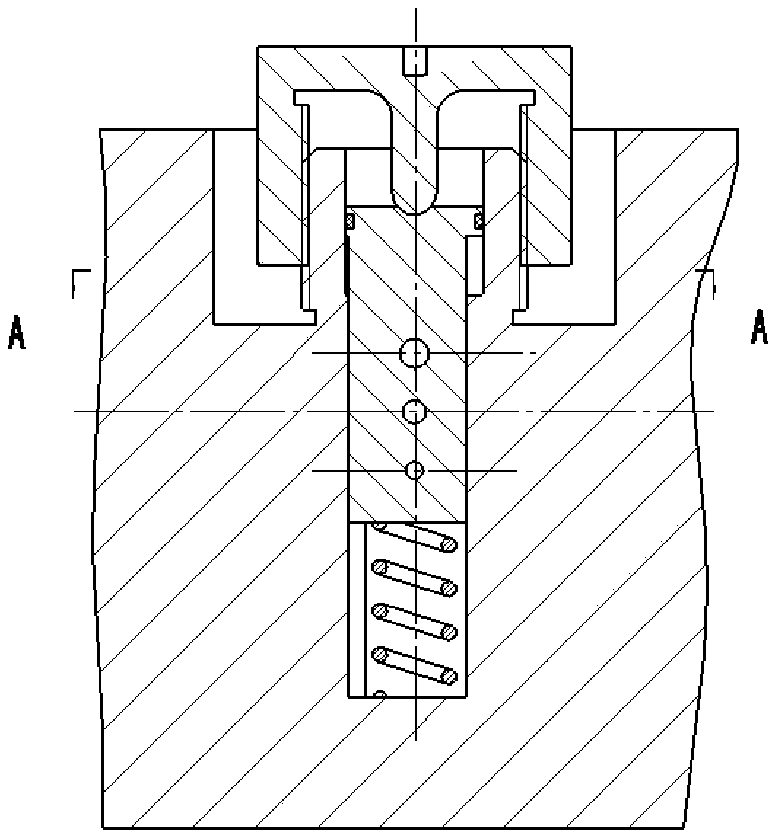

[0020] This embodiment is a cylinder block damper, including a valve core 1 , an adjusting nut 2 , a spring 3 and a sealing ring 4 . Wherein the spring 3 is installed in the damper mounting hole of the cylinder block 5, so that the bottom surface of the spring is attached to the bottom surface of the damper mounting hole. The lower end of the spool 1 is inserted into the mounting hole of the damper, and the valve core is slidably matched with the mounting hole of the damper. An adjusting nut 2 is sleeved at the opening of the damper installation hole, and the pressing rod in the adjusting nut is pressed against the center of the upper end surface of the valve core. When the adjusting nut is rotated, the spool moves up and down under the action of the adjusting nut, so that the damping holes on the spool respectively correspond to and communicate with the oil passage holes on the cylinder block 5 .

[0021] The spool 1 is cylindrical, and there is a radially protruding slider ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com