Device for automatically grinding and detecting square window of valve sleeve of servo valve

A window device and servo valve technology, applied in the field of electro-hydraulic servo, can solve the problems of difficult manufacturing, high precision requirements, and human factors in the grinding process, so as to improve the grinding accuracy and efficiency and solve the process bottleneck.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

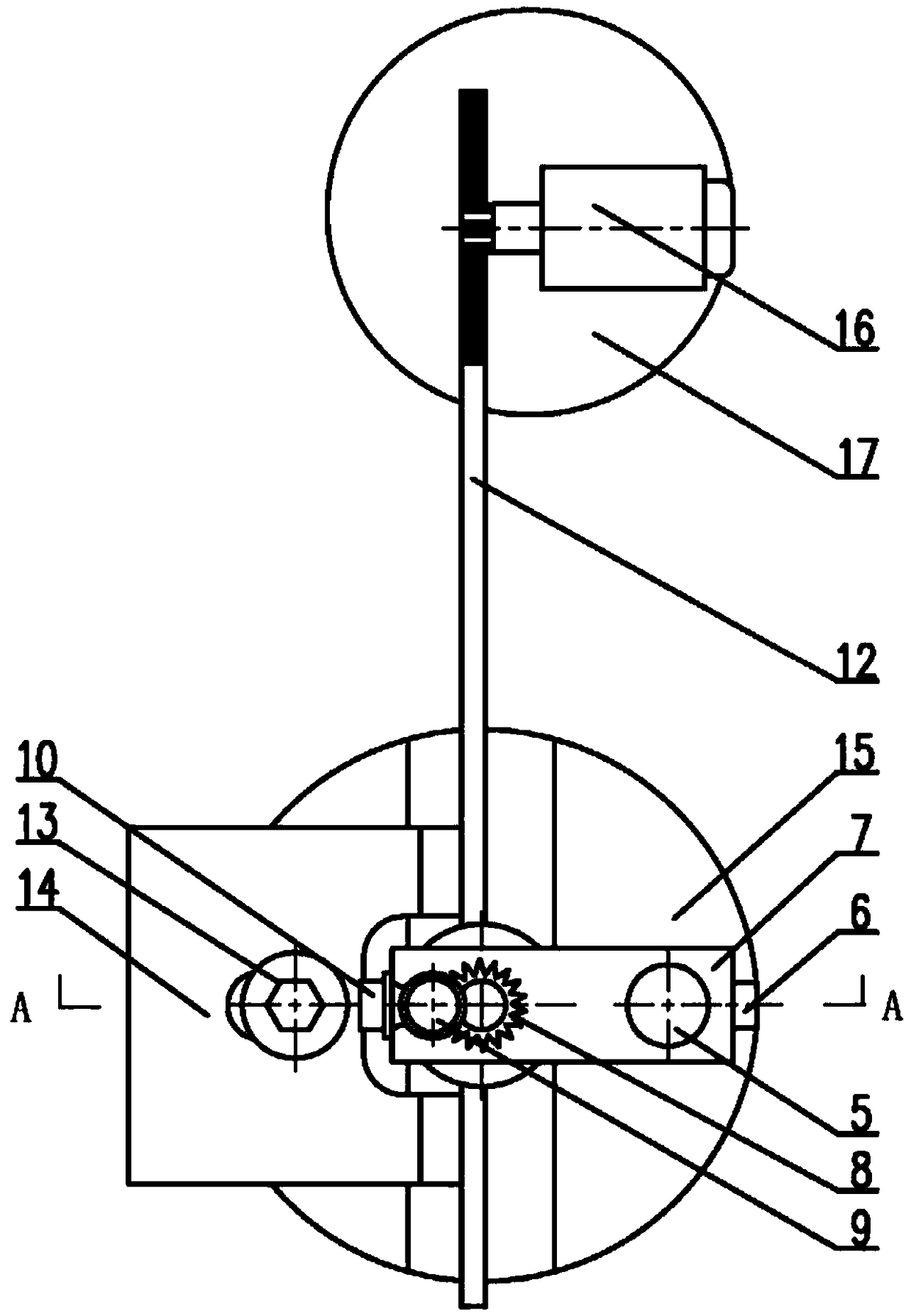

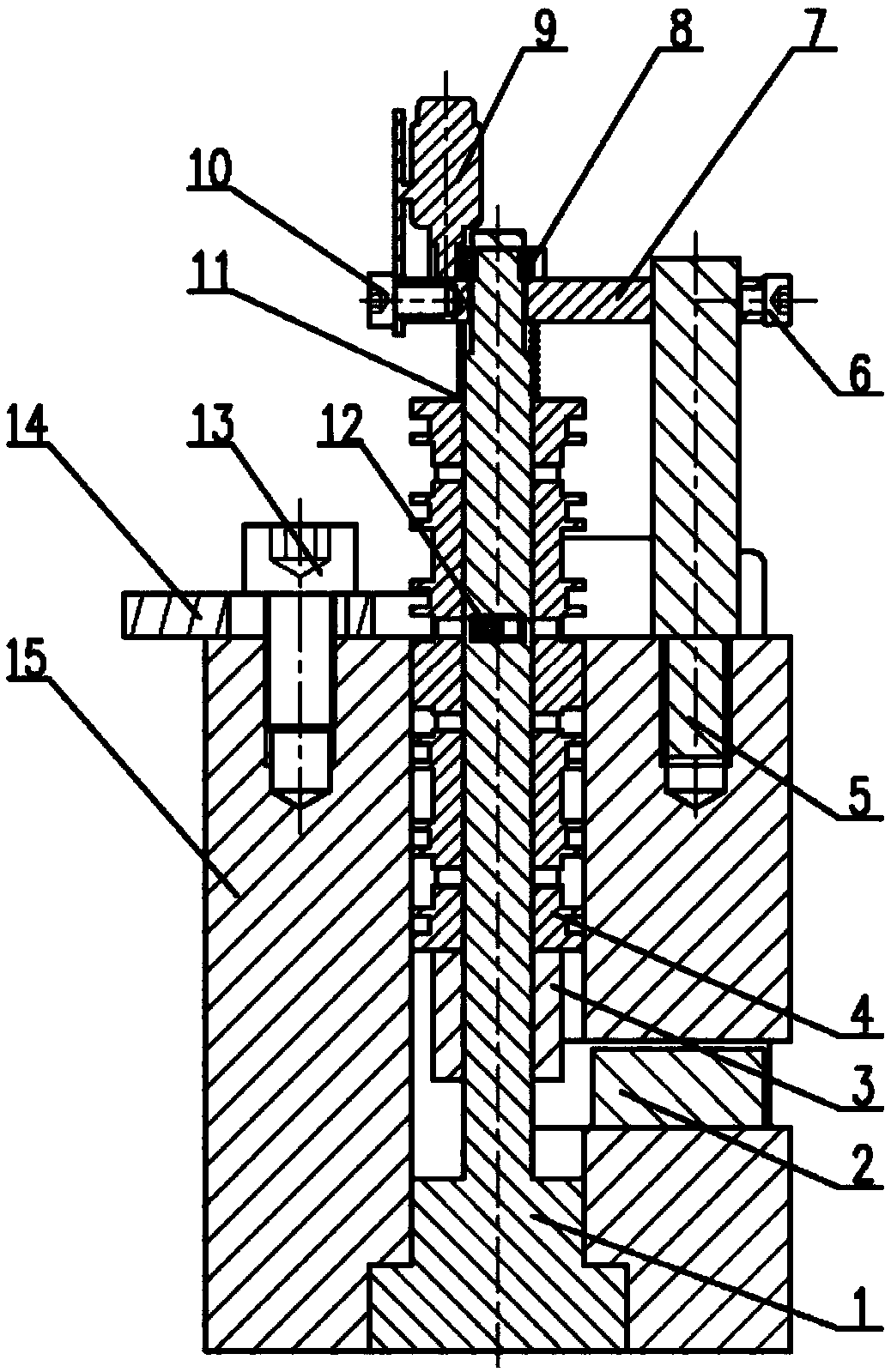

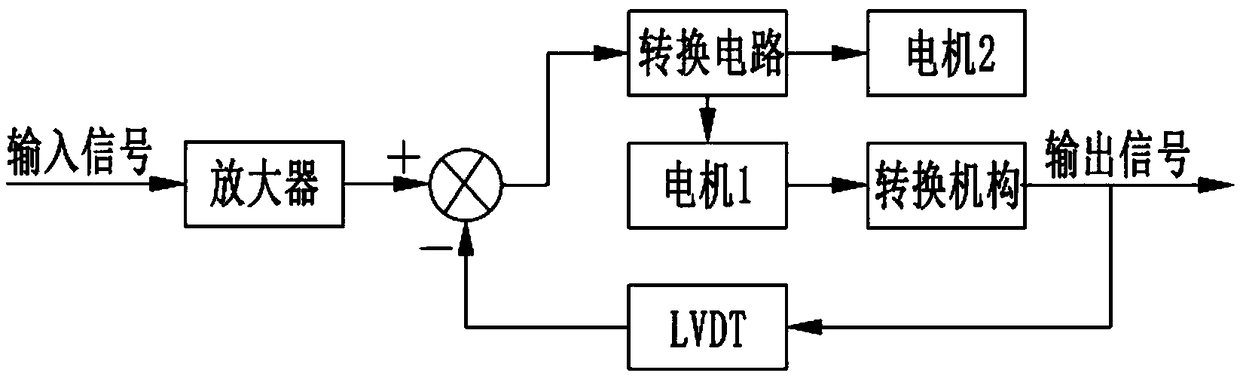

[0017] Such as figure 1 , as shown in 2, an automatic grinding and detection servo valve sleeve square window device, including a mandrel 1, a conversion circuit 2, an LVDT sensor 3, a servo valve sleeve 4, a pillar 5, an M3 screw 6, a pressure plate 7, and an M6 gear Type nut 8, motor one 9, M3.5 screw 10, spring 11, grinding bar 12, M8 screw 13, orientation plate 14, clamp body 15, motor two 16, support table 17, etc. The mandrel 1 is installed in the main hole of the clamp body 15, and fixed through the stepped hole and the M6 gear nut 8; the LVDT sensor 3 and the servo valve sleeve 4 are fixed by gluing the LVDT sensor 3; the conversion circuit 2 and the clamp Specifically, 15 is fixed by buckling; the main hole of the servo valve sleeve 4 is matched with the mandrel 1 through clearance, and a spring 11 is installed between the pressure plate 7 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com