Reducing rotary cold extrusion strengthening process device

A process device and cold extrusion technology, which is applied in the field of cold extrusion strengthening process device, can solve the problems of affecting the roundness of the hole, wear of the inner surface of the mandrel and the bushing, and easy to cause eccentricity, so as to prolong the service life and improve the resistance. Fatigue performance, effect of ensuring reliability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below, in conjunction with the accompanying drawings, preferred embodiments of the present invention are given and described in detail, so that the functions and features of the present invention can be better understood.

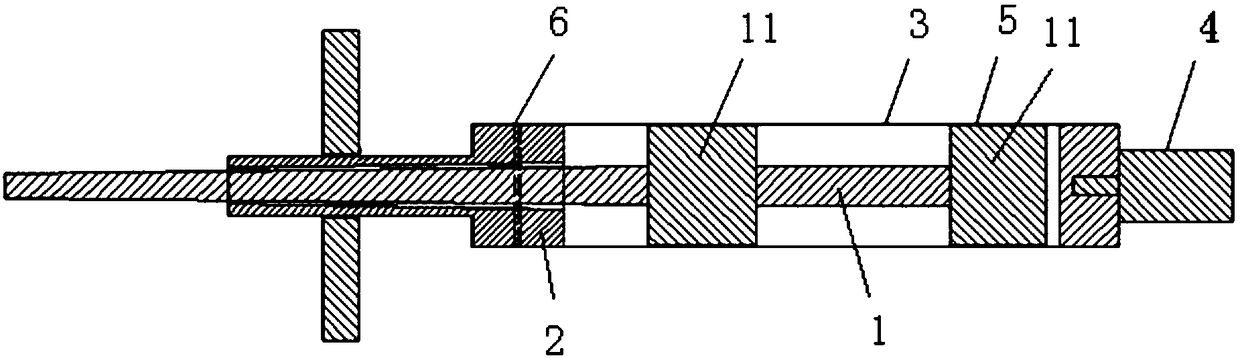

[0029] Such as figure 1 Shown is a variable diameter rotary cold extrusion strengthening process device according to an embodiment of the present invention, which includes a mandrel 1, a bush 2 and a fixed cylinder 3 slidably sleeved on the mandrel 1, the fixed cylinder 3 is fixedly connected to one end of the bushing 2 and sleeved on the mandrel 1 and the bushing 2, and the other end of the fixing cylinder 3 away from the bushing 2 is connected to a motor 4 and a pipeline system, so that The fixed cylinder 3 is driven by the motor 4 to rotate to complete the rotation process, and the fixed cylinder 3 can be filled with hydraulic oil.

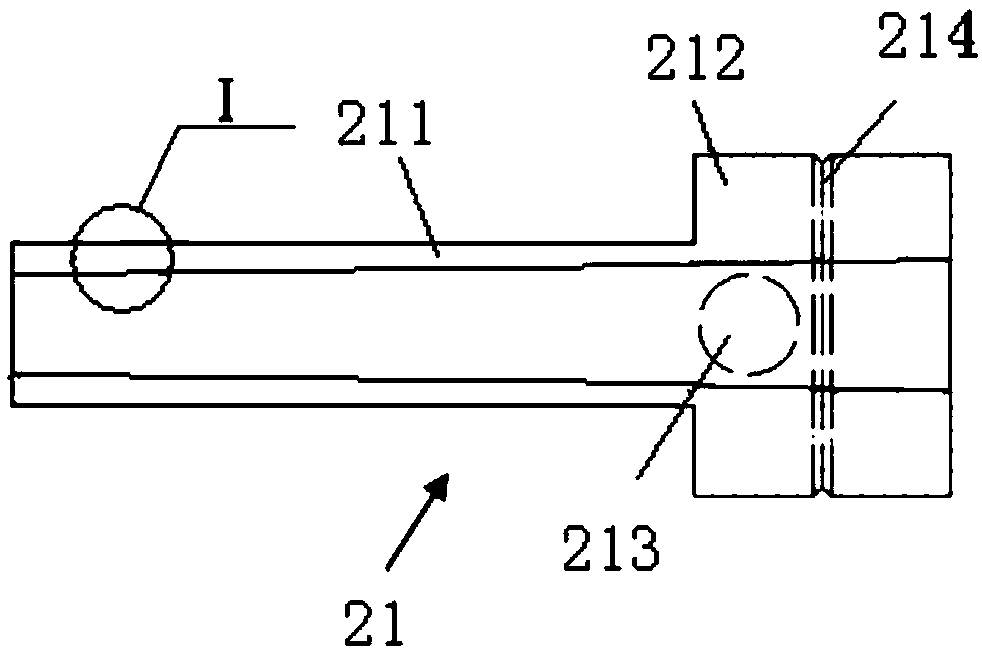

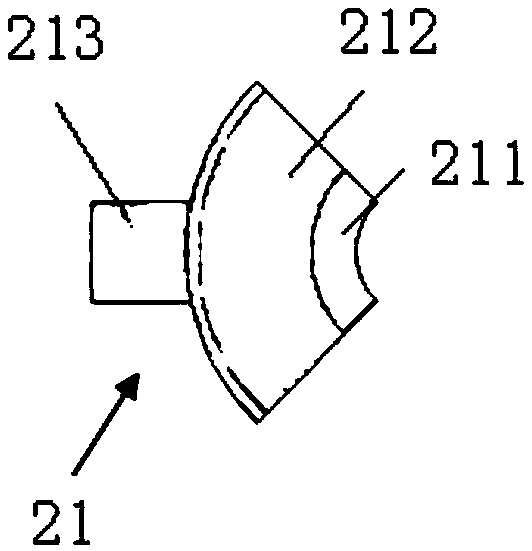

[0030]The mandrel 1 comprises a tapered cylinder and an equal-diameter cylinder, the taper of the tapered cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com