Thermoelectric generation device and power storage system

A technology of temperature difference power generation and storage system, which is applied in circuit devices, battery circuit devices, generators/motors, etc., can solve problems such as unstable temperature differences, and achieve the effect of improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

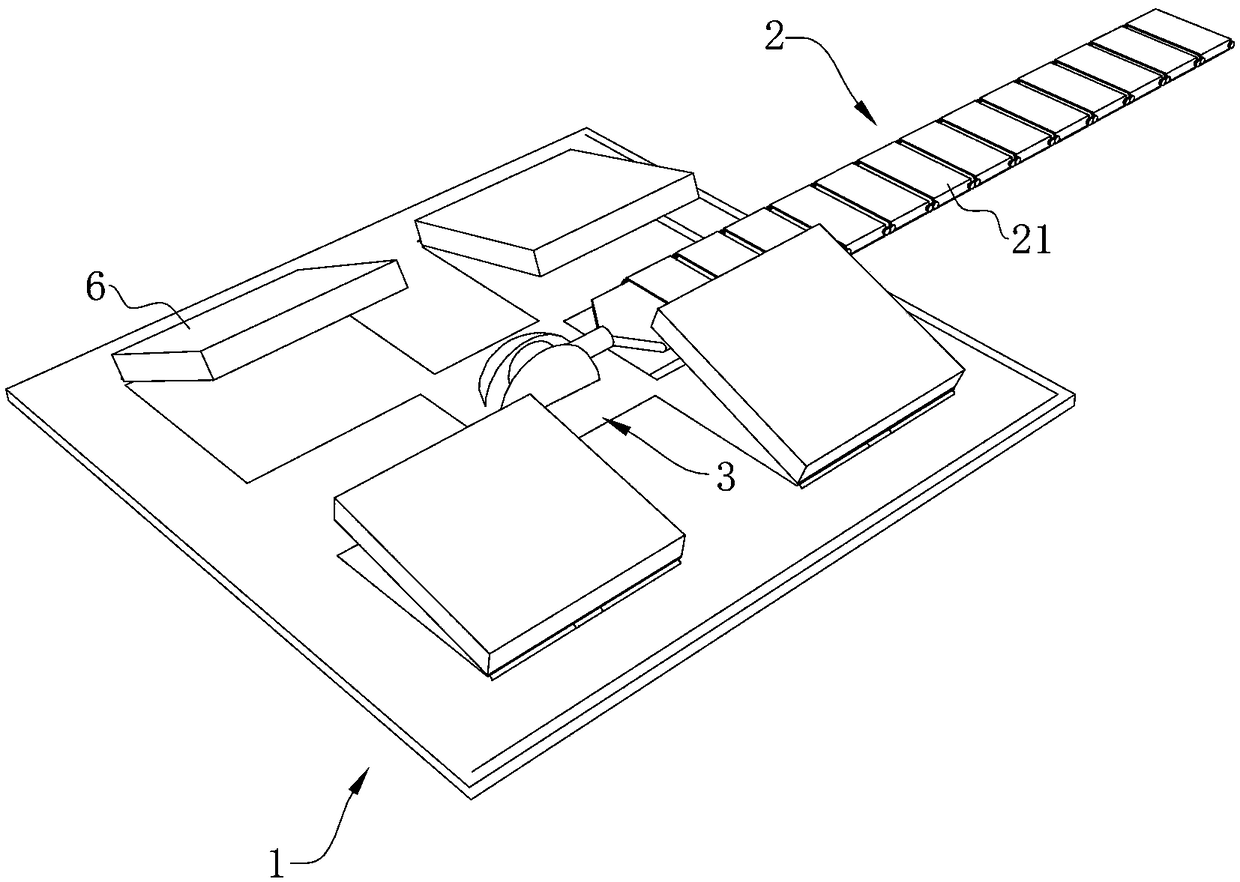

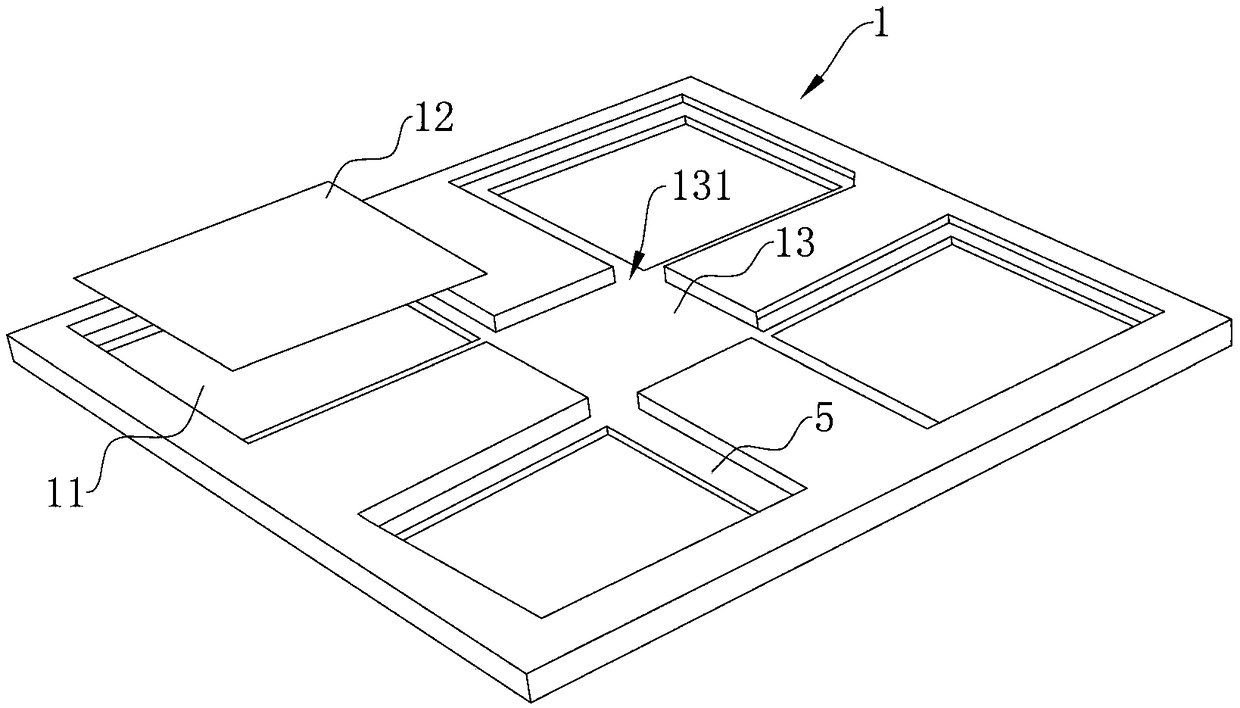

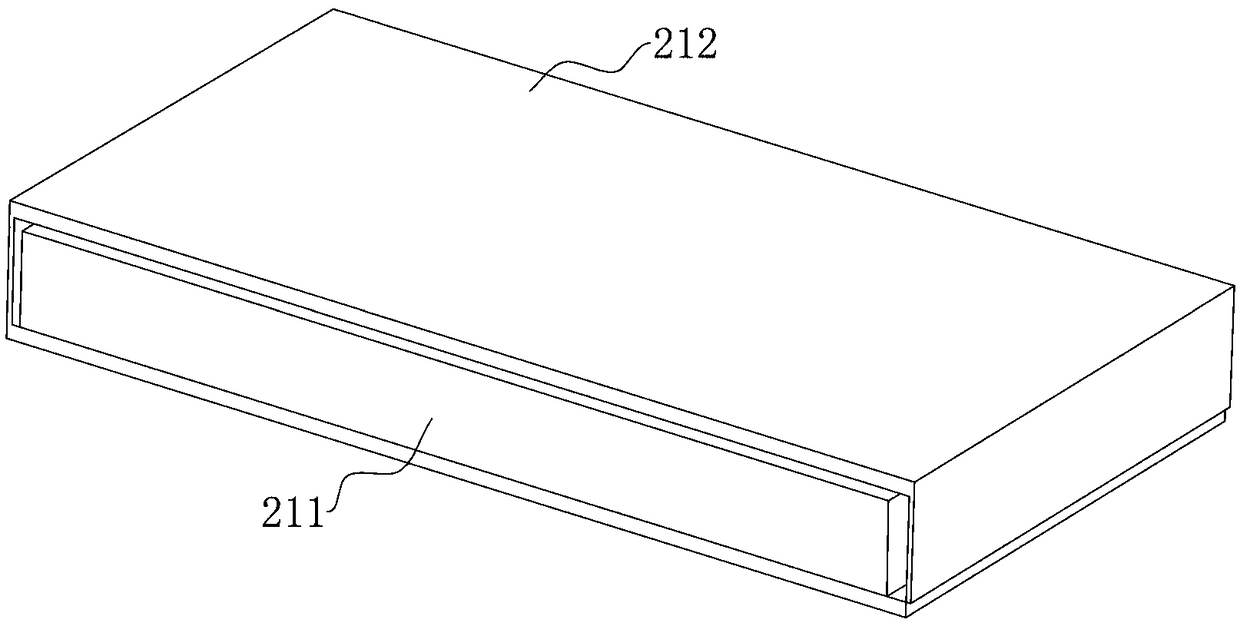

[0031] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides a thermoelectric power generation device, including a heat insulation board 1 and a heat conduction assembly 2 installed on the heat insulation board 1 . The heat insulation board 1 is a square plate made of heat insulation material, and four assembly holes 11 are opened on the upper surface of the heat insulation board 1, wherein the four assembly holes all pass through the heat insulation board 1 and are distributed in a rectangular array, and the four Each assembly hole 11 divides the upper surface of the heat insulation board 1 into a "Tian" shape. A piece of temperature difference sheet 12 is installed in the four assembly holes 11, and an annular support sheet 5 for placing the temperature difference sheet 12 is fixed on the inner wall of the groove of each assembly hole 11, so that the upper surface of the temperature difference sheet 12 serves as a heat conduction surface...

Embodiment 2

[0037] The embodiment of the present invention also provides an electric storage system, such as Figure 5 As shown, it includes a thermoelectric power generation device, wherein the thermoelectric power generation device adopts the thermoelectric power generation device provided by Embodiment 1 of the present invention, and the thermoelectric power generation device provides a stable output voltage. The power storage system also includes a battery. A booster module is connected to the output end of the thermoelectric power generation device, and the output end of the booster module is connected to the battery. Since the voltage directly generated by the thermoelectric sheet is usually relatively low, even if the integrated four-chip temperature difference Compared with the commercial voltage available for home appliances, the voltage generated by the thermoelectric power generation device is boosted by the booster module, and the boosted current is transmitted to the battery f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com