Accelerated aging test method for polymer material xenon lamp in environment simulating typical xerothermic climate of China

A technology of polymer materials and test methods, which is applied in the field of accelerated aging test of polymer materials by xenon lamp, can solve the problems of long, often need one year or even many years to evaluate the results, unfavorable detection evaluation, poor test repeatability, etc. The effect of saving test time, facilitating standardization and simple test operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

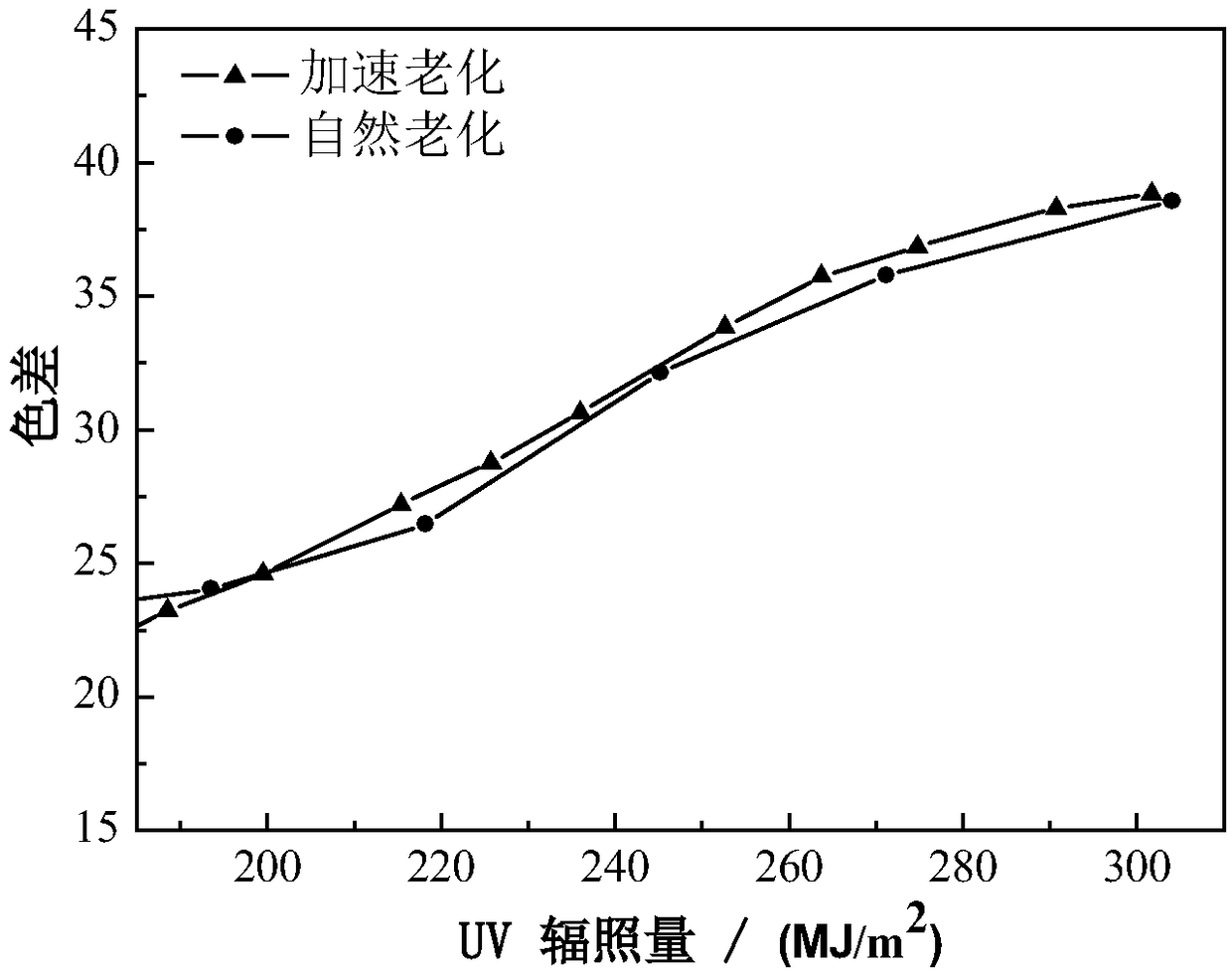

[0034] The xenon lamp accelerated aging test method for polymer materials that simulates the typical dry and hot climate environment in my country uses the typical polymer material polystyrene (PS) as the sample, and the color difference as the key performance index. It specifically includes the following steps:

[0035] (1) Selection of test equipment: choose a water-cooled rotating drum type xenon lamp aging test chamber, and the inner / outer filter of the light source is made of BORO / BORO borosilicate glass;

[0036] (2) Preparation of samples: According to the requirements of color difference test, a sample with a size of 60mm*80mm*3mm is prepared by injection molding;

[0037] (3) Setting of test parameters: the main test parameters are as follows: light intensity: 0.60W / m 2 @340nm; test chamber temperature: 50°C, blackboard temperature: 70°C; relative humidity: 20%; continuous light, do not turn off the lights, do not spray;

[0038] (4) Determination of test time: Examp...

Embodiment 2

[0054] Xenon arc accelerated aging test method for polymer materials that simulates the typical dry and hot climate environment in my country. The polypropylene / nano-calcium carbonate composite material is used as the sample, the mass ratio of polypropylene and nano-calcium carbonate is 95 / 5, and the surface morphology of the sample after aging It is a key indicator, which specifically includes the following steps:

[0055] (1) Selection of test equipment: In Example 1, a water-cooled rotating drum type xenon lamp aging test box is selected, and the inner / outer filter of the light source is made of BORO / BORO borosilicate glass;

[0056] (2) Sample preparation: According to the surface morphology test requirements of the stereomicroscope, a sample with a size of 60mm*80mm*3mm was prepared by injection molding;

[0057] (3) Setting of test parameters: the main test parameters are as follows: light intensity: 0.60W / m 2 @340nm; test chamber temperature: 50°C, blackboard temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com