Shear key damping support capable of realizing stiffness degradation and energy dissipation

A shear key and damping technology, applied in the direction of building types, buildings, building components, etc., can solve the problems of small bearing capacity, complex structure of the limit damper, inconvenient on-site installation, etc., to achieve easy installation, good ductility, The effect of convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

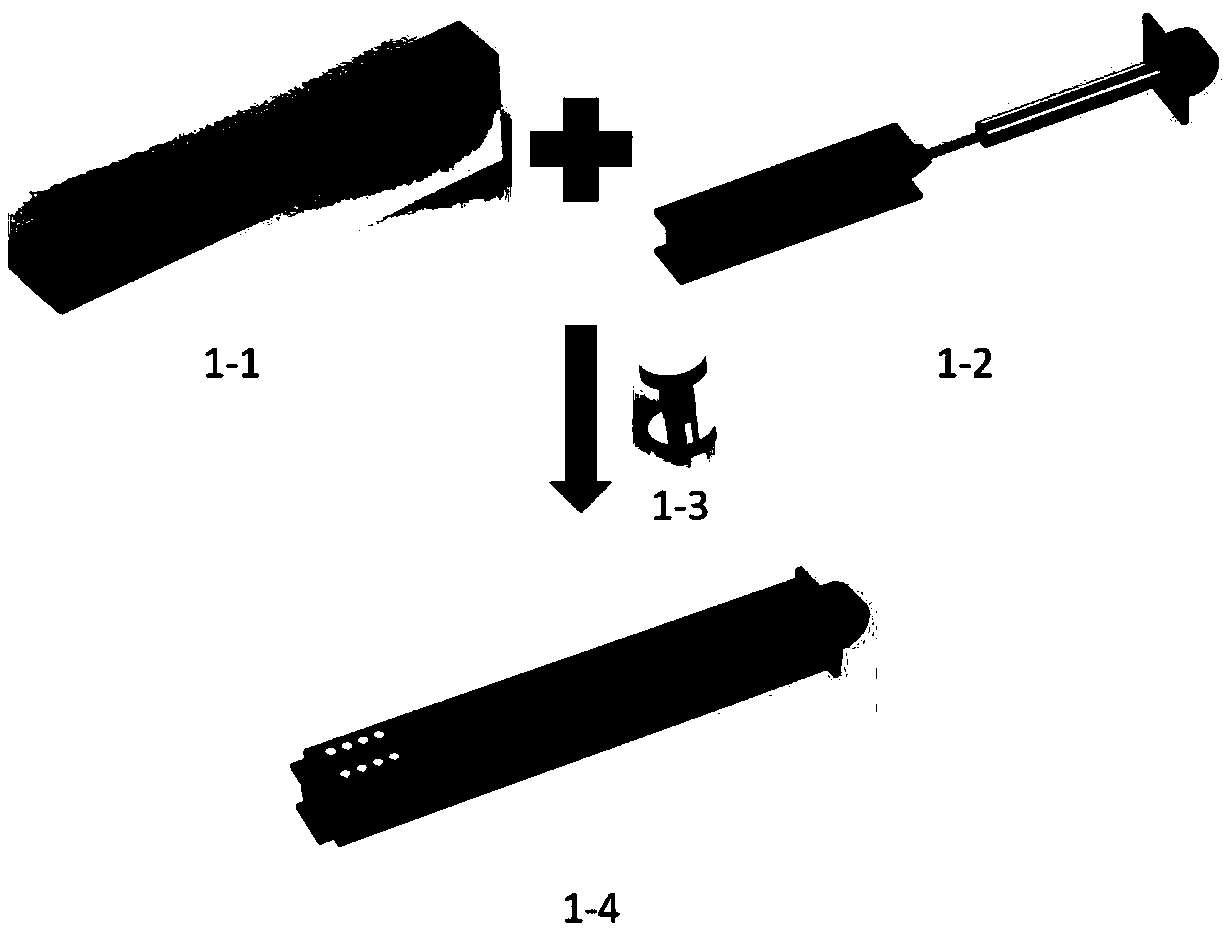

[0034] Such as figure 1 As shown, a shear key damping support that can realize stiffness degradation and energy dissipation is characterized in that it consists of three parts: a jacket constraint support, an embedded sliding support, and an embedded damper. One section of the outer restraint support and the embedded sliding support is respectively bolted or welded to the beam-column joints of the structure, and the overlapping parts are nested and connected with a shear key bolt group, and one end of the embedded damper is connected to the embedded sliding support with bolts or Welding, and the other end is connected to the common node of the jacket restraint support at the beam-column node.

Embodiment 2

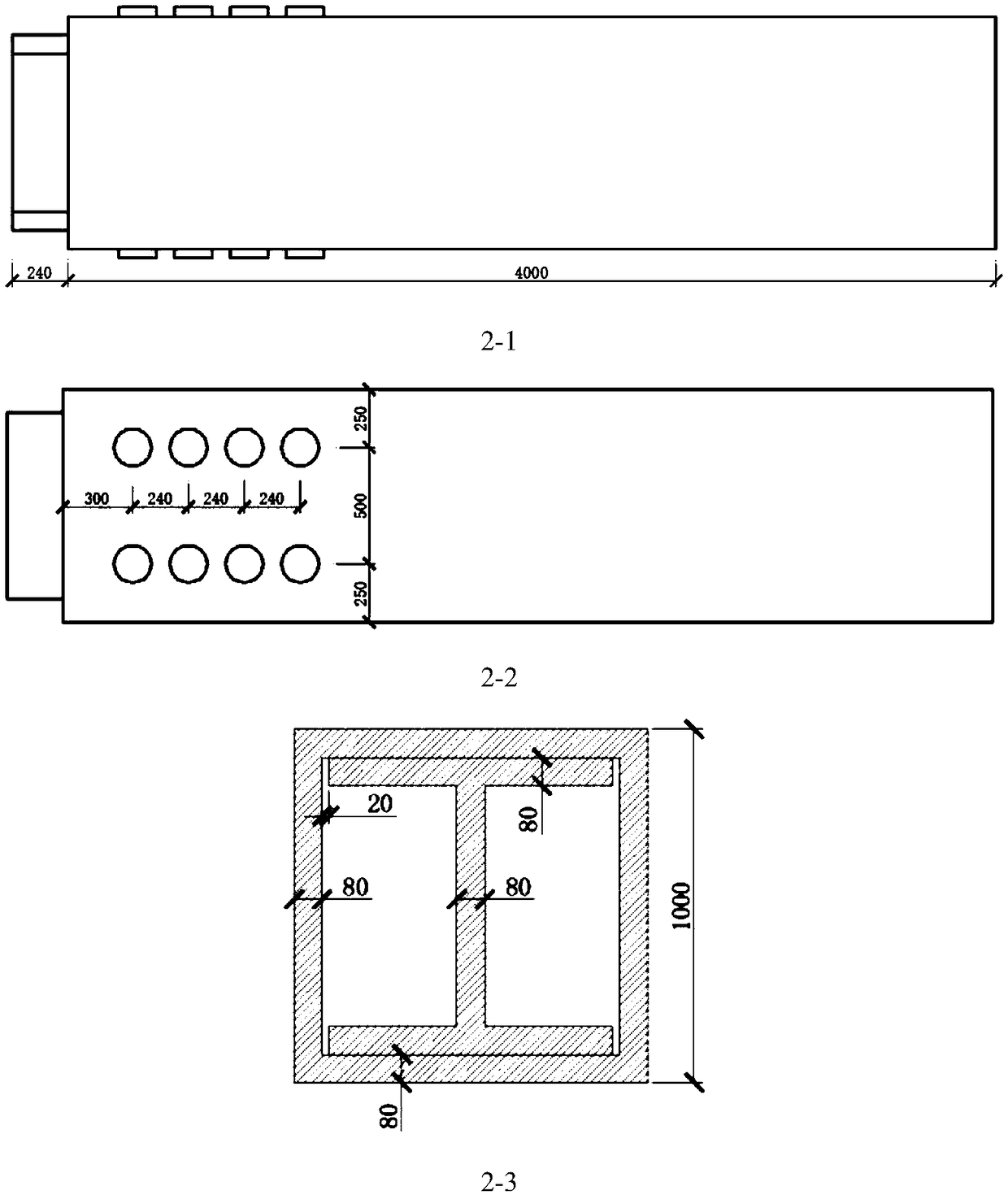

[0036] On the technical scheme of embodiment 1, such as figure 2 As shown, the box-shaped steel pipes used for the restraint support of the jacket have holes at one end that is not connected to the beam-column node. The height of the I-shaped steel used for the embedded sliding support is the same as the height of the inner edge of the box-shaped steel pipe. The width of the flange of the I-shaped steel is slightly smaller than the width of the inner edge of the box-shaped steel pipe to prevent the deformation of the steel from hindering sliding. There are holes at one end, and the opening positions are the four flanges of the I-shaped steel, distributed along the I-shaped steel, and the distance of the holes along the width direction of the flange is the same as the distance of the holes on the box-shaped steel pipe along the width direction.

[0037] In order to realize the resistance to shear failure of the shear key bolt group and to be replaceable, the outer restraint su...

Embodiment 3

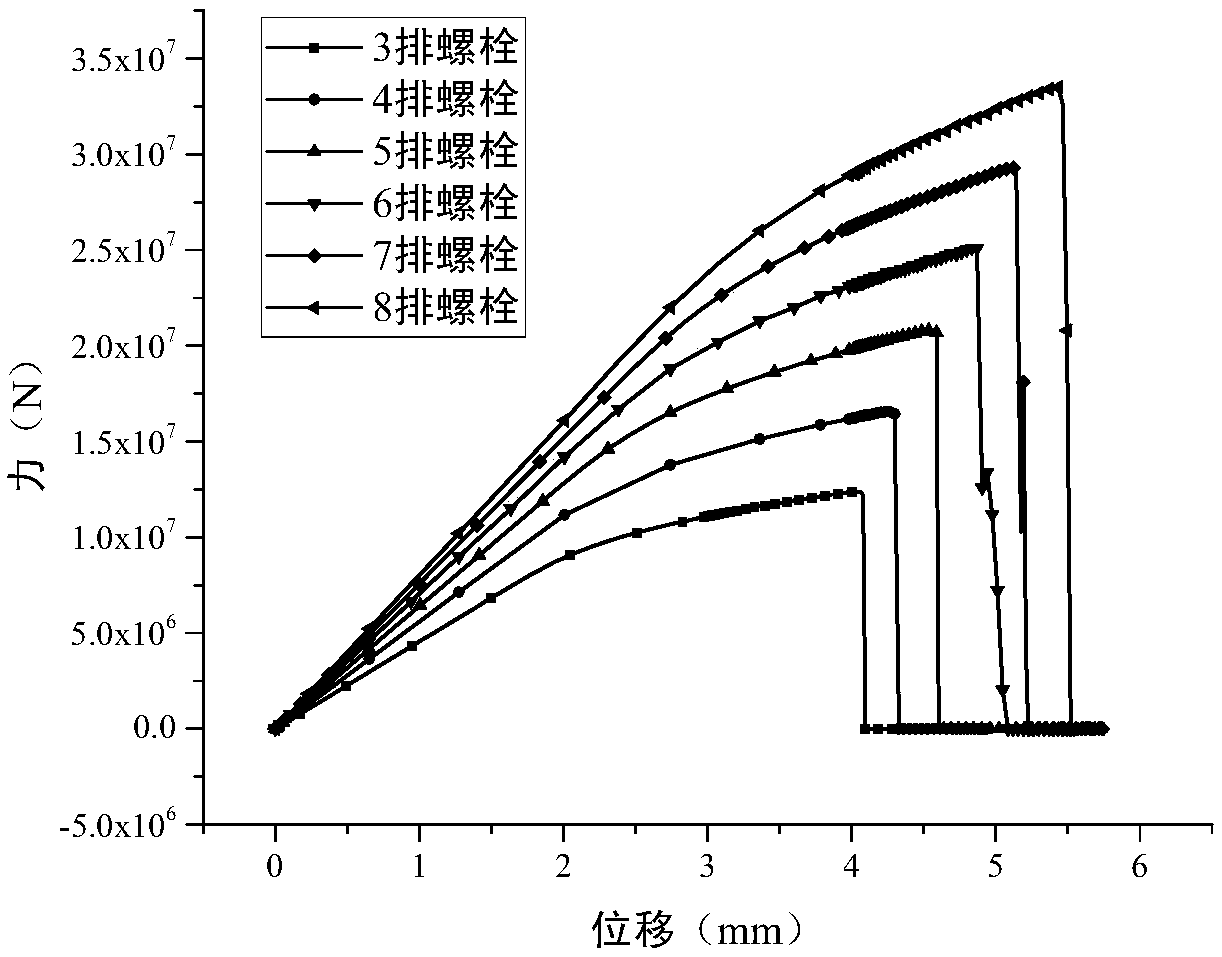

[0040] Comparing the frame-shear key damping support structure applying the technical solution of Embodiment 2 with the frame-buckling-resistant support structure not applying the present invention, the structural arrangement is as follows Figure 4 As shown, shear key damping braces or buckling-resistant braces are applied to a two-story steel-reinforced concrete megaframe structure. The first floor of the giant frame is 42 meters, and the structure is 84 meters high. The cross-sectional size of the frame column is 2000×2000mm, and the steel content is 5%; the cross-sectional size of the frame beam is 1000×2000mm, and the steel content is 2.15%. Just now they were all Q390, and the concrete grades were all C60.

[0041] One-way static horizontal loading is carried out on the structure, and the internal force at the bottom of the frame column and the development of concrete compression damage at the bottom of the compressed column are extracted. Compression damage factors dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com