Natural grass and artificial grass-mixed lawn and preparation method thereof

A technology of natural grass and artificial grass, which is applied in textiles, papermaking, woven fabrics, construction, etc. It can solve the problems of excessive gaps in the woven base fabric of artificial grass, insufficient adhesion of artificial grass threads, and lack of hydrophobic and breathable performance, etc., to achieve Excellent binding force, easy transportation and transplantation, and the effect of protecting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Base fabric weft yarn: PP weft yarn density is 400 weft / m; weft yarn weight is 5000Dtex;

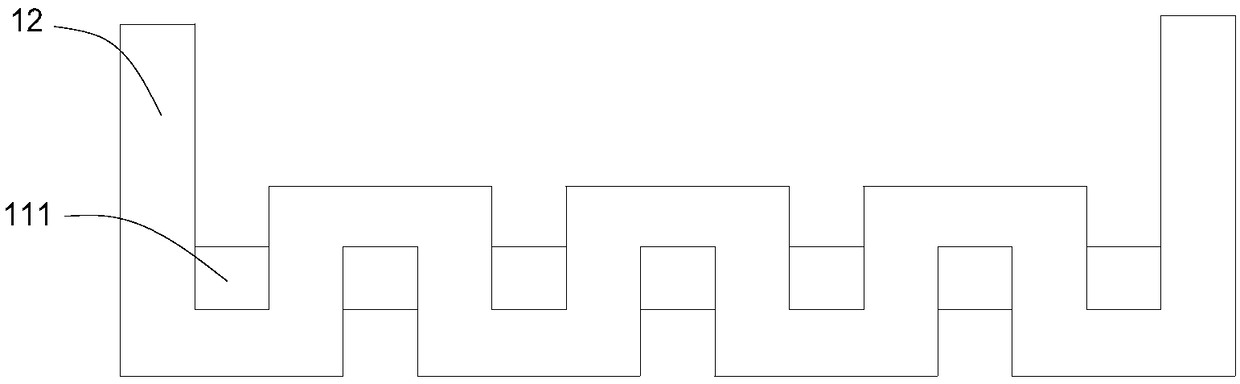

[0050] Bottom fabric warp yarn: each warp yarn group is provided with 6 first warp yarns and 3 second warp yarns; the first warp yarns are arranged in pairs; the first warp yarns use ramie fiber; the total density of the first warp yarns and the second warp yarns is 240 warps / m ;

[0051] Artificial turf: use PE artificial turf; the density of artificial turf is 80 rows / m; the weight of artificial turf is 13000Dtex; every 7 weft yarns are passed around, the artificial turf is lifted; the artificial turf protrudes from the base fabric The height is 48mm.

Embodiment 2

[0053] Base fabric weft yarn: PP weft yarn density is 500 weft / m; weft yarn weight is 6000Dtex

[0054] Bottom fabric warp yarn: each warp yarn group is provided with 3 first warp yarns and 3 second warp yarns;

[0055] The first warp yarn uses cotton and linen blended fibers; the total density of the first warp yarn and the second warp yarn is 260 / meter;

[0056] Artificial turf: use PP artificial turf; the density of artificial turf is 150 lines / m; the weight of artificial turf is 17000Dtex; every 7 weft yarns are passed around, the artificial turf is lifted; the artificial turf protrudes from the base fabric The height is 35mm.

Embodiment 3

[0058] Base fabric weft yarn: PP weft yarn density is 350 weft / m; weft yarn weight is 7000Dtex;

[0059] Bottom fabric warp yarn: each warp yarn group is provided with 8 first warp yarns and 4 second warp yarns; the first warp yarns are arranged in pairs; the first warp yarns use sisal fiber; the total density of the first warp yarns and the second warp yarns is 280 warps / rice;

[0060] Artificial turf: use PA artificial turf; the density of artificial turf is 200 lines / m; the pound weight of artificial turf is 15000Dtex; the artificial turf is lifted every 5 weft yarns; the artificial turf protrudes from the base fabric The height is 40mm.

[0061] Test Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com