A non-uniform wetting surface with fractal properties and its preparation method

A non-uniform and fractal technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve the problem of inconsistency of dynamic process considerations, achieve the coordination of heat flux density distribution and heat flux density distribution, improve The effect of critical heat flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] specific implementation

[0023] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described below in conjunction with specific embodiments and with reference to the accompanying drawings.

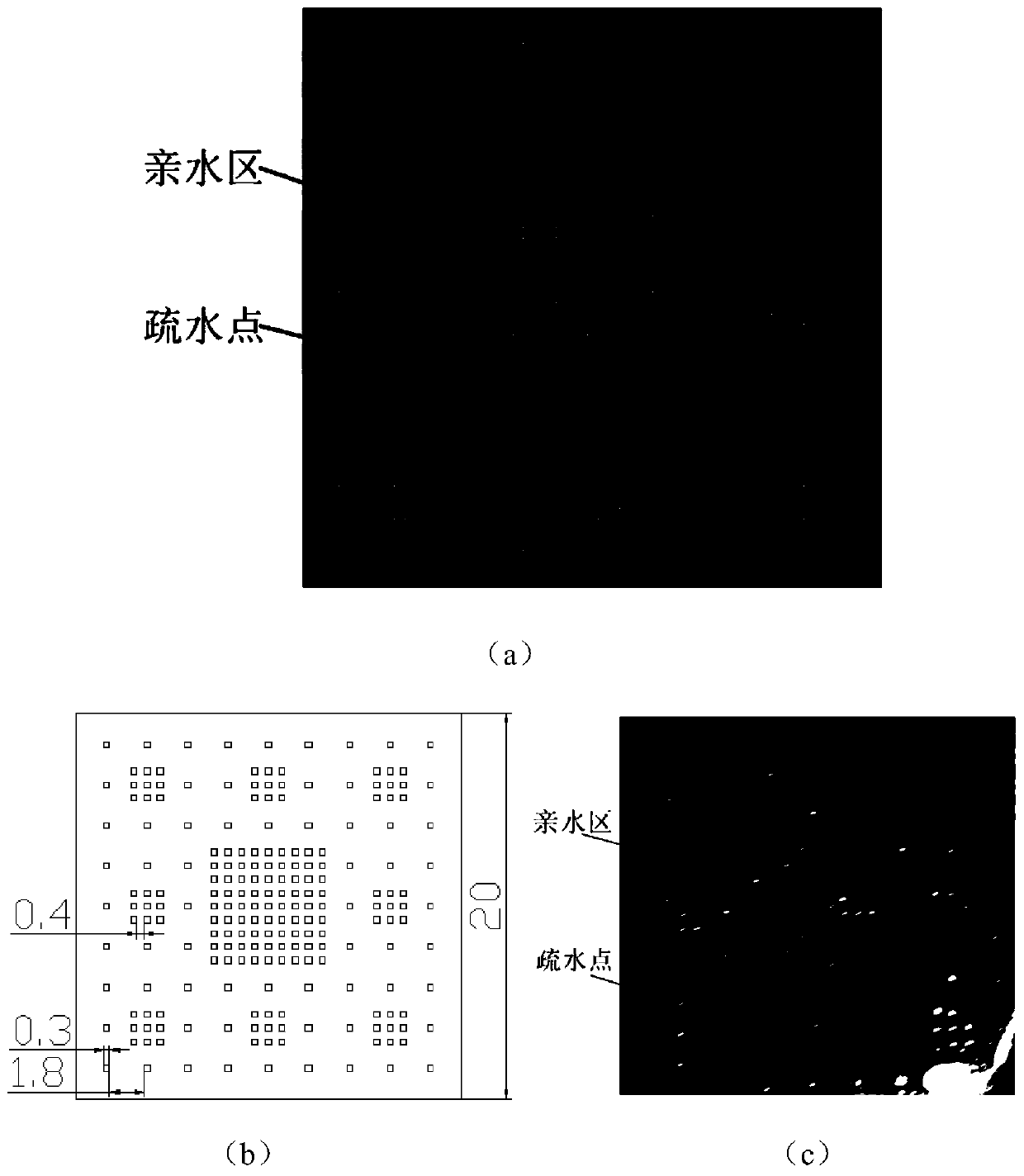

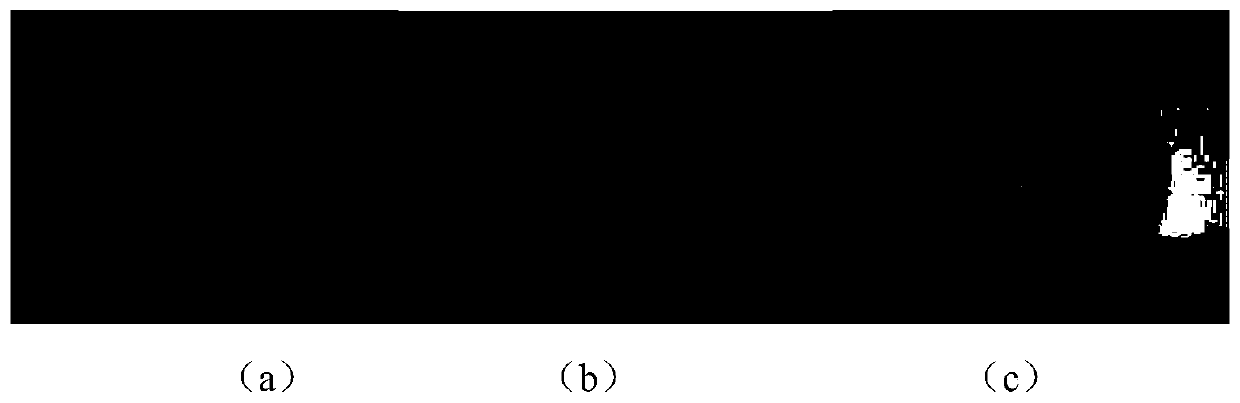

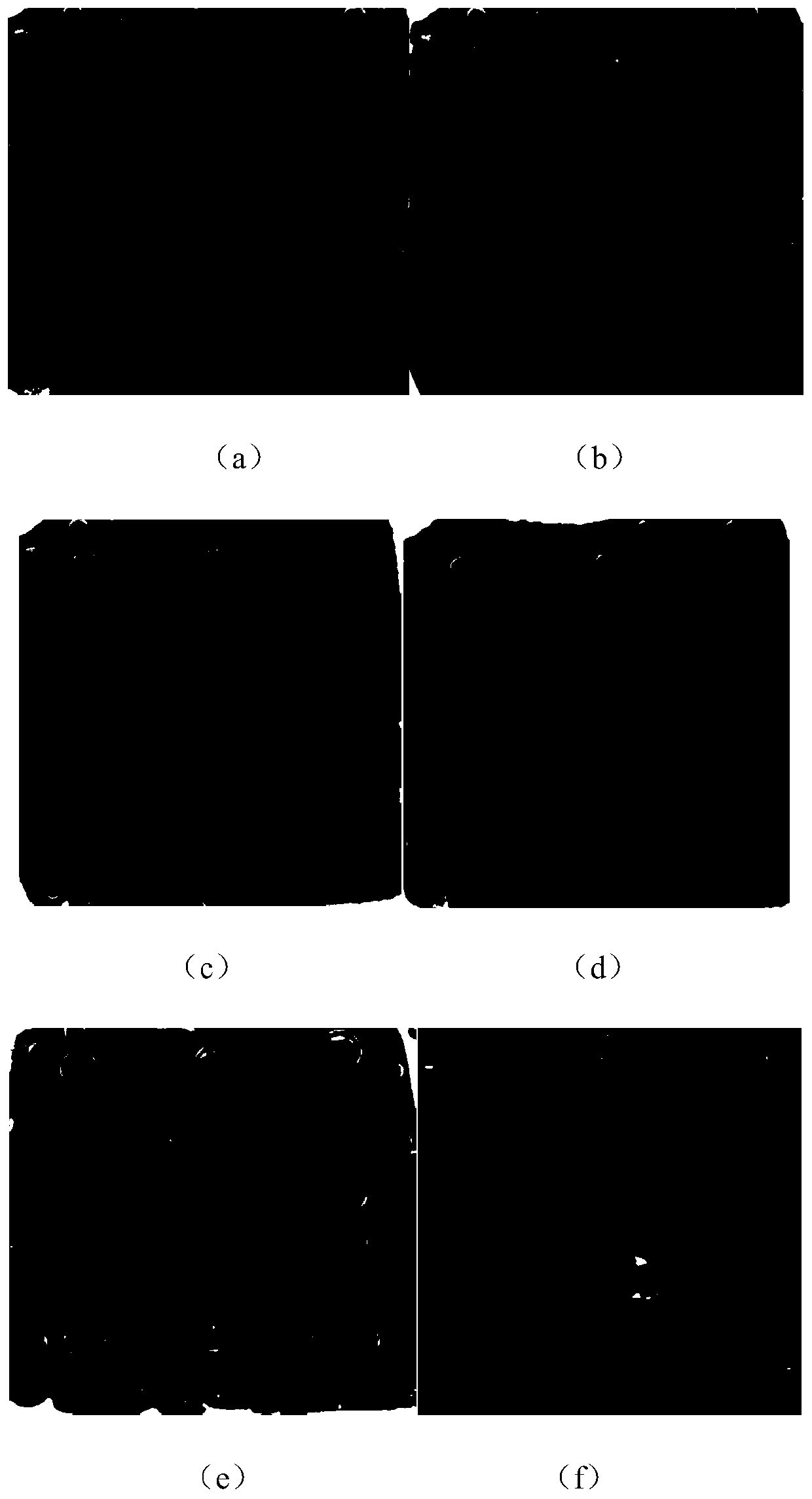

[0024] see figure 1 , the non-uniform wetting surface with fractal properties of the present invention includes hydrophobic lattice regions and hydrophilic channels with strong wettability, and the hydrophobic lattice regions are crossed and penetrated by hydrophilic channels. Among them, the hydrophobic area is composed of a hydrophobic lattice distributed according to the fractal characteristics of the Sierpinski carpet curve. The static water contact angle of the hydrophobic lattice area is not less than 140°, and the static water contact angle of the hydrophilic channel area is less than 20°.

[0025] According to the fractal characteristics of the Sierpinski carpet curve in the hydrophobi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com