A kind of ethyl ester type fish oil refining process

A technology of ethyl ester type fish oil and processing technology, which is applied in the direction of fat oil/fat refining, fatty acid esterification, fat production, etc., can solve the problems of production cost, high equipment investment, harsh reaction conditions, expensive equipment investment, etc., and achieve improvement The effect of product yield and quality, no equipment corrosion, and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

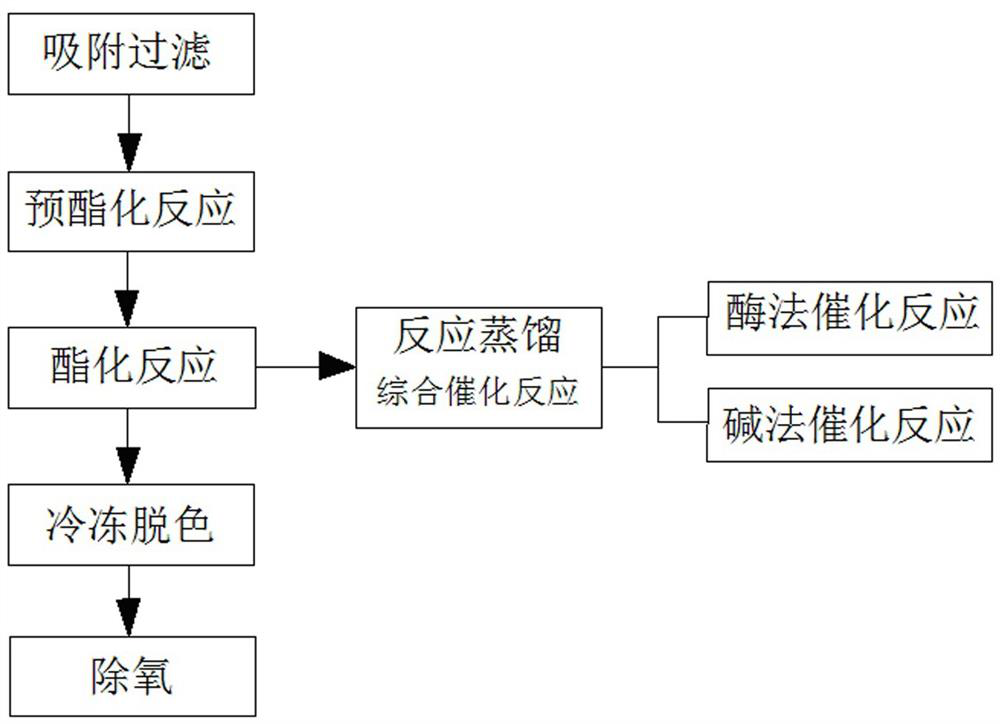

[0037] A kind of ethyl ester type fish oil refining process, specifically comprises the following steps:

[0038] S1. Pretreatment of crude fish oil: add activated clay to the crude fish oil as an adsorbent, the amount of activated clay is 3% of the total mass of fish oil, use a thermal magnetic stirrer to stir and adsorb the crude fish oil, and the vacuum degree is -0.2MPa , at a temperature of 68°C, heat-preserve and stir for 30 minutes, then lower the fish oil to room temperature, filter and remove the adsorbent, and put the fish oil for use;

[0039] S2, pre-esterification reaction: pump the fish oil prepared in step S1 into the reactor, and add the compound acid and ethanol which have been mixed uniformly with concentrated sulfuric acid as the main body in the reactor; the compound acid with concentrated sulfuric acid as the main body includes The mass fraction in parts by weight is a mixture of 60 parts of concentrated sulfuric acid, 20 parts of oxalic acid and 20 parts ...

Embodiment 2

[0044] A kind of ethyl ester type fish oil refining process is characterized in that: concretely comprises the following steps:

[0045] S1. Pretreatment of crude fish oil: adding activated carbon to the crude fish oil as an adsorbent, the amount of activated carbon added is 5% of the total mass of the fish oil, and using a thermal magnetic stirrer to stir and adsorb the crude fish oil. The vacuum degree is -1.0MPa, the temperature Under the condition of 72°C, heat preservation and stirring for 40 minutes, then lower the fish oil to room temperature, filter and remove the adsorbent, and then use the fish oil for later use;

[0046] S2, pre-esterification reaction: pump the fish oil prepared in step S1 into the reactor, and add organic acid and ethanol that have been mixed uniformly in the reactor; the organic acid is methanesulfonic acid, p-toluenesulfonic acid and sulfamic acid A mixture of acids; the mixture in the reactor is heated to 80°C, the condensed water is turned on ...

Embodiment 3

[0051] A kind of ethyl ester type fish oil refining process is characterized in that: concretely comprises the following steps:

[0052] S1. Pretreatment of crude fish oil: add graphene to the crude fish oil as an adsorbent, and the amount of graphene added is 5% of the total mass of the fish oil. Use a thermal magnetic stirrer to stir and adsorb the crude fish oil, and the vacuum degree is -0.6MPa , under the condition of 70°C, heat preservation and stirring for 35 minutes, then lower the fish oil to room temperature, filter and remove the adsorbent, and put the fish oil for use;

[0053] S2, pre-esterification reaction: pump the fish oil prepared in step S1 into the reaction kettle, and add the well-mixed SO in the reaction kettle 4 2- / M x o y type solid superacid and ethanol; the SO 4 2- / M x o y type solid superacid is SO 4 2- / ZrO 2 Solid super acid or SO 4 2- / TiO 2 One of the solid superacids, the acid strength is less than -11.94; the mixture in the react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com