A kind of dye-doped liquid crystal microcapsule material and preparation method thereof

A liquid crystal material and doped technology, applied in the fields of fine chemical industry and material science, can solve the problems of inability to achieve multi-color color rendering of a single liquid crystal microcapsule, high driving voltage of liquid crystal microcapsules, and obvious light scattering effect, and achieve color rendering. Bright, good dichroism and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

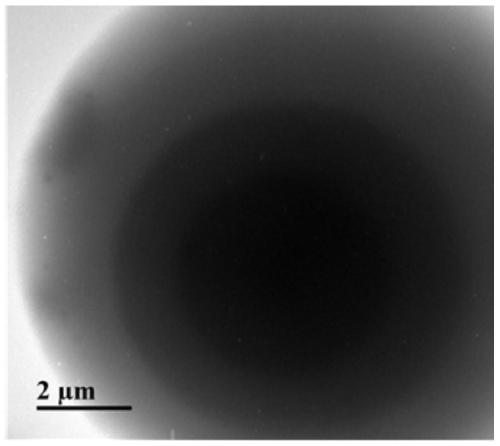

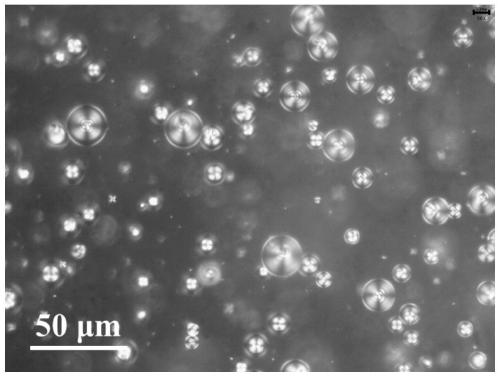

[0051] Mix 0.01g of C.I. Disperse Red 60 and 1g of mixed liquid crystal E7, heat it until it is just completely dissolved and become transparent, stir at this temperature for 0.5h, cool down until the mixture appears color or turbid, then raise the temperature until it is just transparent, and stir at constant temperature After 0.5h, a red dye-doped liquid crystal was obtained.

[0052] Keep the obtained red dye-doped liquid crystal at the clearing point temperature, and add it dropwise to the aqueous solution containing 0.2g lauryl polyoxyethylene ether at the same temperature under the action of mechanical stirring, and emulsify at a high speed to form a uniform dispersion ; Add 0.5g butyl methacrylate and 0.5g isoprene, 0.1g divinylbenzene and 0.05g trifluoroethyl methacrylate to the liquid crystal dispersion dropwise after uniform mixing, and continue to emulsify for 60 minutes . Then transfer to a four-necked flask with condensing reflux and stirring device, nitrogen gas...

Embodiment 2

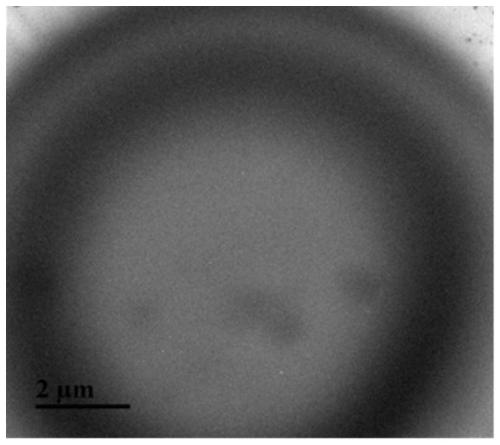

[0058] Mix 0.01g of C.I. Disperse Blue 359 and 1g of mixed liquid crystal E7, heat it until just completely dissolved and become transparent, stir at this temperature for 0.5h, cool down until the mixture appears color or turbid, then raise the temperature until it is just transparent, and stir at constant temperature After 0.5h, the blue dye-doped liquid crystal was obtained.

[0059] Keep the obtained blue dye-doped liquid crystal at the clearing point temperature, and add it dropwise to an aqueous solution containing 0.1g OP-10 at the same temperature under mechanical stirring, and emulsify at a high speed to form a uniform dispersion; 0.5 g of hexyl methacrylate, 0.25 g of styrene, 0.375 g of divinylbenzene and 0.225 g of trifluoroacetyl trifluoromethanesulfonate were evenly mixed and added dropwise to the liquid crystal dispersion, and the emulsification was continued for 60 minutes. Then transfer to a four-necked flask with condensing reflux and stirring device, nitrogen...

Embodiment 3

[0064] Mix 0.001g of C.I. Disperse Blue 60 and 1g of mixed liquid crystal 5CB, heat it until it is completely dissolved and become transparent, stir at this temperature for 0.5h, cool down until the mixture appears color or turbid, then raise the temperature until it is just transparent, and stir at constant temperature After 0.5h, the blue dye-doped liquid crystal was obtained.

[0065]The obtained blue dye-doped liquid crystal is kept at the clearing point temperature, and it is added dropwise to an aqueous solution containing 0.5g SE-10 at the same temperature under mechanical stirring, and is emulsified at a high speed to form a uniform dispersion; 0.1 g of butyl acrylate and 0.2 g of methyl methacrylate, 0.003 g of diacetone acrylamide and 0.003 g of hexafluorobutyl methacrylate were evenly mixed and added dropwise to the liquid crystal dispersion, and the emulsification was continued for 60 minutes. Then transfer to a four-necked flask with condensing reflux and stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com