Non-ferrous metal raffinate pretreatment method before membrane pretreatment

A non-ferrous metal, pretreatment technology, applied in the direction of special treatment targets, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of poor effect of trace organic matter, and achieve the goal of eliminating complex water quality and secondary pollution, and increasing salinity , Improve the effect of effluent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

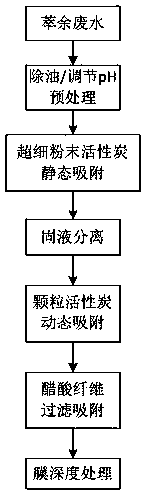

[0024] Embodiment 1: as figure 1 As shown, the concrete steps of the pre-membrane pretreatment method of the non-ferrous metal extraction raffinate are as follows:

[0025] (1) Pretreat the raffinate wastewater, separate and remove the remaining suspended oil through filtration, etc., and adjust the pH value to 1.5;

[0026] (2) Put coconut shell ultrafine powder activated carbon with a particle size of 0.05 μm into the pretreated extraction wastewater, stir to make the ultrafine powder activated carbon fully contact with the extraction wastewater, and perform static adsorption through ultrafine powder activated carbon. Powdered activated carbon selectively adsorbs and extracts macromolecular organic pollutants in wastewater, and separates solids and liquids after adsorption saturation; the static adsorption reaction conditions are that the wastewater temperature is 5°C, the adsorption contact reaction time is 1min, and the mixer is used for mechanical stirring at a stirring s...

Embodiment 2

[0029] Embodiment 2: as figure 1 As shown, the concrete steps of the pre-membrane pretreatment method of the non-ferrous metal extraction raffinate are as follows:

[0030] (1) Pretreat the raffinate wastewater, separate and remove the remaining suspended oil through filtration, etc., and adjust the pH value to 7;

[0031] (2) Put coconut shell ultrafine powder activated carbon with a particle size of 0.5 μm into the pretreated extraction wastewater, stir to make the ultrafine powder activated carbon fully contact with the extraction wastewater, and perform static adsorption through ultrafine powder activated carbon. Powdered activated carbon selectively adsorbs and extracts macromolecular organic pollutants in wastewater, and separates solids and liquids after adsorption saturation; the static adsorption reaction conditions are that the wastewater temperature is 25 ° C, the adsorption contact reaction time is 10 minutes, and the air is introduced into the air for stirring by ...

Embodiment 3

[0034] Embodiment 3: as figure 1 As shown, the concrete steps of the pre-membrane pretreatment method of the non-ferrous metal extraction raffinate are as follows:

[0035] (1) Pretreat the raffinate wastewater, separate and remove the remaining suspended oil through filtration, etc., and adjust the pH value to 3;

[0036] (2) Put coconut shell ultrafine powder activated carbon with a particle size of 3 μm into the pretreated extraction wastewater, stir to make the ultrafine powder activated carbon fully contact with the extraction wastewater, perform static adsorption through ultrafine powder activated carbon, and use ultrafine powder Activated carbon selectively adsorbs and extracts macromolecular organic pollutants in wastewater, and separates solids and liquids after the adsorption is saturated; the static adsorption reaction conditions are that the wastewater temperature is 20°C, the adsorption contact reaction time is 10 minutes, and the air compressor is used for stirri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com