Three-dimensional porous graphene robot dexterous hand

A three-dimensional porous, graphene technology, applied in the field of robotics, can solve the problems of low reliability, difficulty in grasping the scale and shape of the robot arm, and many degrees of freedom of the manipulator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

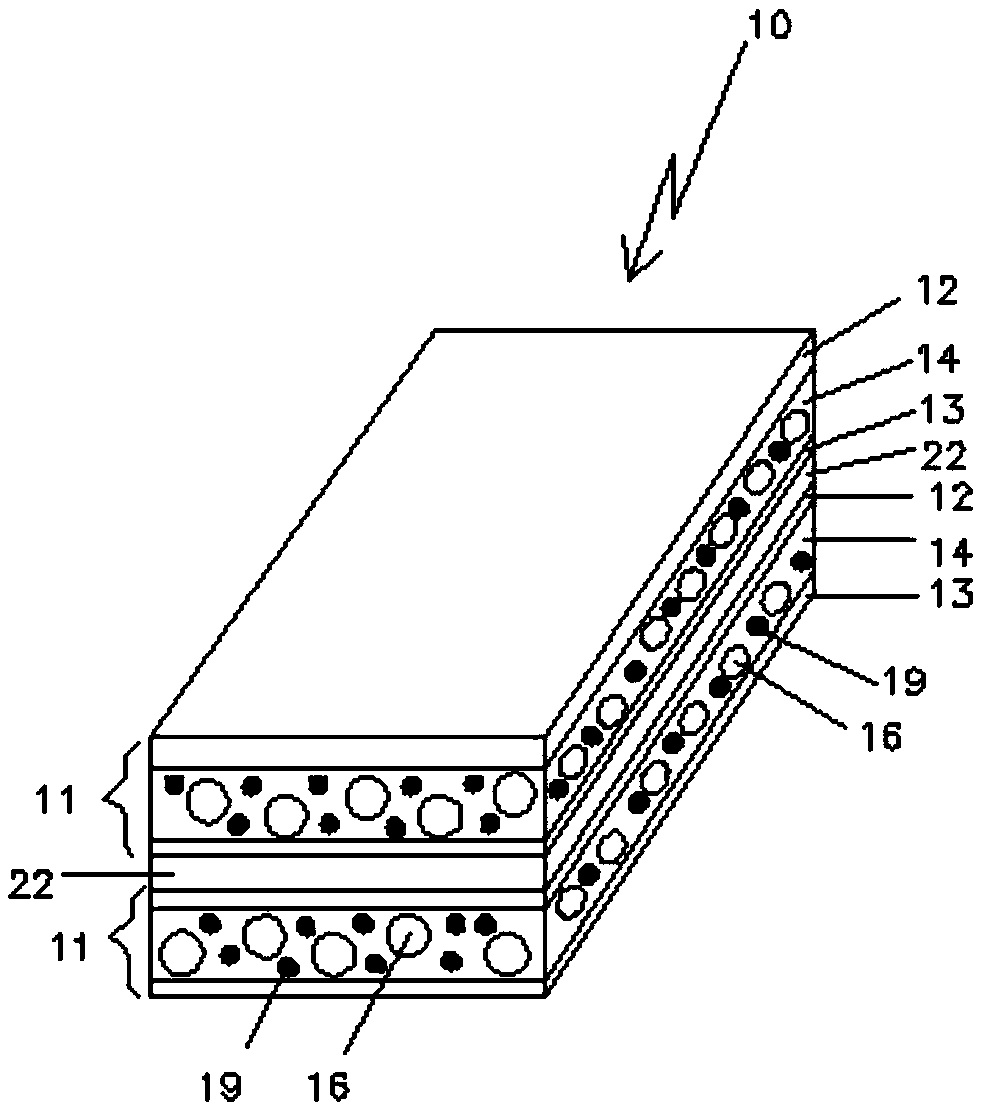

[0035] Three-dimensional porous graphene-based robotic five-fingered dexterous hand

[0036] The structural representation of the five-finger joint dexterous hand of the three-dimensional porous graphene type robot of embodiment 1 of the present invention (see Figure 4 ), the schematic diagram of the structure of the three-dimensional porous graphene type unit driver before deformation driving (see figure 1 ), the schematic diagram of the structure of the three-dimensional porous graphene type unit driver when it is deformed (see figure 2 ), the structural schematic diagram of the three-dimensional porous graphene type multi-unit stacked driver (see image 3 ).

[0037] Three-dimensional porous graphene-type robotic five-fingered dexterous hand 1 includes: multiple three-dimensional porous graphene-type multi-fingered fingers 2, three-dimensional porous graphene-type wrist joints 3, palm 4, intelligent controller, different types of sensors 5, circuit control Board, stret...

Embodiment 2

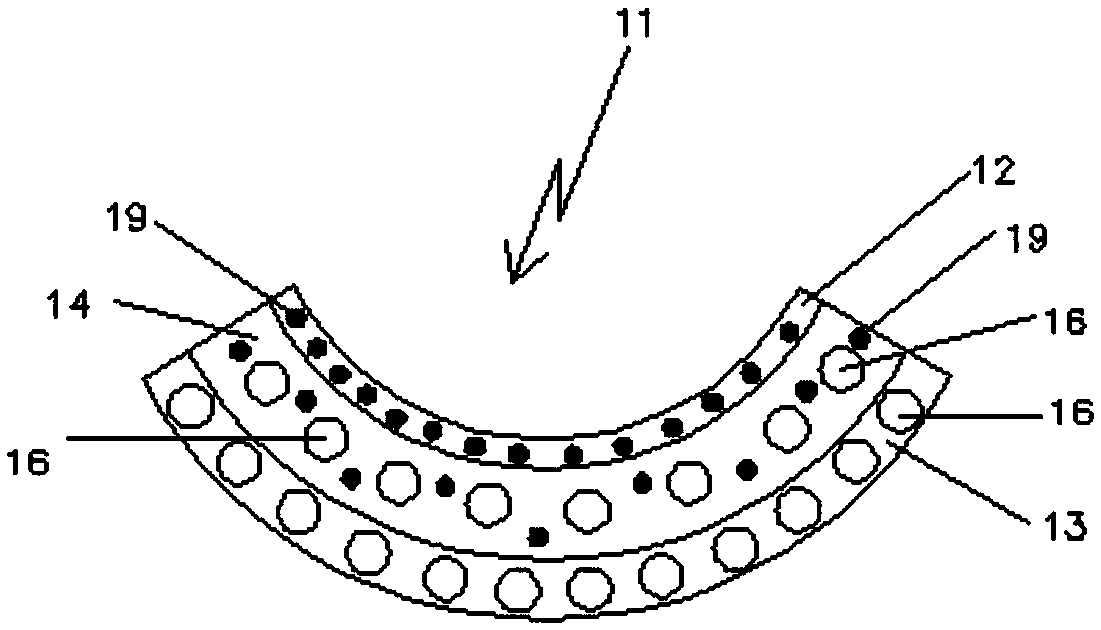

[0045] Three-dimensional porous graphene-type robotic multi-fingered soft dexterous hand17

[0046] The structural representation of the multi-fingered soft body dexterous hand 17 of the three-dimensional porous graphene type robot of embodiment 2 of the present invention (see Figure 5 ), the structural schematic diagram of the three-dimensional porous graphene type unit driver 11 before deformation driving (see figure 1 ), the structural representation of the three-dimensional porous graphene type unit driver 11 when it is deformed and driven (see figure 2 ), the structural representation of the three-dimensional porous graphene type multi-unit stacked driver 10 (see image 3 ).

[0047] The three-dimensional porous graphene type robot multi-fingered soft dexterous hand 17 according to Embodiment 2 of the present invention includes: a plurality of three-dimensional porous graphene type robot soft fingers 18, knuckle connectors, different types of sensors 5, palms 20, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com