Preparation method for ammonium phosphomolybdate composite gel adsorption material

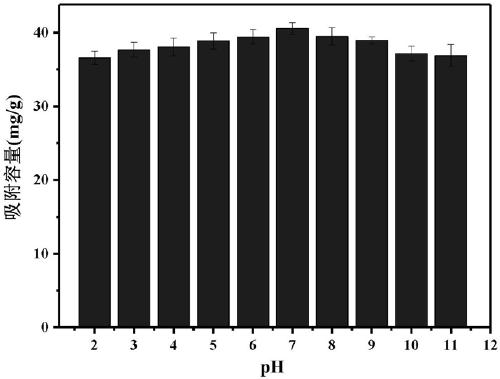

A composite gel and ammonium phosphomolybdate technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, alkali metal compounds, etc., can solve problems such as granulation and molding difficulties, and achieve weakened agglomeration and reduced crosslinking Effects on density, improved stability and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of ammonium phosphomolybdate composite gel adsorption material, comprising the following steps:

[0032] Step 1. Add 10g of sodium alginate and 1g of PG into 40g of deionized water, heat and stir at 80°C for 4 hours until uniformly mixed;

[0033] Step 2: ultrasonically disperse 1 g of ammonium phosphomolybdate in the aqueous solution, add the mixture after cooling to room temperature, and stir for 5 hours to make the mixed solution evenly mixed;

[0034] Step 3, adding the mixed solution obtained in Step 2 dropwise into a boric acid solution of 1% calcium ion with a syringe for chemical cross-linking, and soaking for 24 hours to obtain a formed composite gel with a particle size of 1-5 mm;

[0035] Step 4: Separation, fully washing with distilled water for 4 times and drying to obtain a composite gel adsorption material.

Embodiment 2

[0037] A preparation method of ammonium phosphomolybdate composite gel adsorption material, comprising the following steps:

[0038] Step 1. Add 5g of ammonium alginate and 1g of PG into 45g of deionized water, heat and stir at 80°C for 3 hours until uniformly mixed;

[0039] Step 2: ultrasonically disperse 1 g of ammonium phosphomolybdate in the aqueous solution, add the mixture after cooling to room temperature, and stir for 4 hours to make the mixed solution evenly mixed;

[0040] Step 3, adding the mixed solution obtained in Step 2 dropwise into a 10% calcium ion boric acid solution with a syringe for chemical cross-linking, and soaking for 24 hours to obtain a formed composite gel with a particle size of 1-5 mm;

[0041] Step 4: Separation, fully washing with distilled water for 4 times and drying to obtain a composite gel adsorption material.

Embodiment 3

[0043] A preparation method of ammonium phosphomolybdate composite gel adsorption material, comprising the following steps:

[0044] Step 1. Add 1g of sodium alginate and 1g of PG into 50g of deionized water, heat and stir at 80°C for 2 hours until the mixture is uniform;

[0045] Step 2: ultrasonically disperse 1 g of ammonium phosphomolybdate in the aqueous solution, add the mixture after cooling to room temperature, and stir for 2 hours to make the mixed solution evenly mixed;

[0046] Step 3, adding the mixed solution obtained in Step 2 dropwise into a boric acid solution of 1% calcium ion with a syringe for chemical cross-linking, and soaking for 24 hours to obtain a formed composite gel with a particle size of 1-5 mm;

[0047] Step 4: Separation, fully washing with distilled water for 4 times and drying to obtain a composite gel adsorption material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com