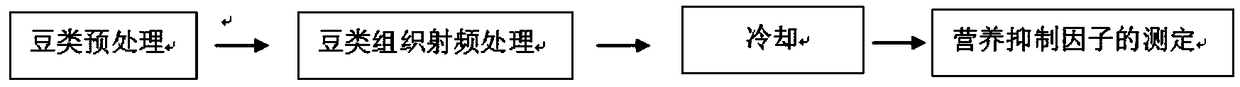

Method for passivating anti-nutritional factors in beans

A technology of inhibitory factors and beans, which is applied in the field of passivation of nutritional inhibitors in beans, can solve the problems of reducing protein nutritional value and digestibility, and achieves low activity, reduced water consumption and energy consumption, and fast speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Application of radio frequency heat treatment device (recorded in the patent application for invention with publication number CN104782758A) to process soybeans, the specific steps are as follows:

[0029] (1) Pretreatment: select soybeans of the same variety, put them in a thermoplastic basket with good electrical insulation, and the thickness of the sample stack is 40mm (thickness is less than the distance between the plates);

[0030] (2) RF treatment: the thermoplastic basket is placed on the conveyor belt at the center of the pole plate under the radio frequency treatment chamber. The operating frequency of the radio frequency treatment device is 27.12MHz, the power is set to 2.0kW, the distance between the pole plates is 45mm, and the sample thickness is 40mm. The auxiliary temperature in the radio frequency processing device is 50-55°C, the processing time is 300s, and the temperature of the beans in the radio frequency device is maintained within the range of 120...

Embodiment 2

[0035] Application of radio frequency heat treatment device (recorded in the patent application for invention with publication number CN104782758A) to process soybeans, the specific steps are as follows:

[0036] (1) Pretreatment: select soybeans of the same variety, put them in a thermoplastic basket with good electrical insulation, and the sample stacking thickness is 90mm (thickness is less than the distance between the plates);

[0037] (2) RF treatment: the thermoplastic basket is placed on the conveyor belt at the center of the pole plate under the radio frequency treatment chamber. The operating frequency of the radio frequency treatment device is 27.12 MHz, the power is set to 1.5 kW, the distance between the pole plates is 100 mm, and the sample thickness is 90 mm. The auxiliary temperature in the radio frequency processing device is 50-55°C, the processing time is 500s, and the temperature of beans in the radio frequency device is maintained within the range of 120-14...

Embodiment 3

[0042] Application of radio frequency heat treatment device (recorded in the patent application for invention with publication number CN104782758A) to process soybeans, the specific steps are as follows:

[0043] (1) Pretreatment: select soybeans of the same variety, put them in a thermoplastic basket with good electrical insulation, and the thickness of the sample stack is 60mm (thickness is less than the distance between the plates);

[0044] (2) RF treatment: place the thermoplastic basket on the conveyor belt at the center of the pole plate under the radio frequency treatment chamber, the operating frequency of the radio frequency treatment device is 27.12MHz, the power is set to 8.0kW, the distance between the pole plates is 70mm, and the thickness of the sample is 60mm. The auxiliary temperature in the radio frequency processing device is 50-55°C, the processing time is 150s, and the temperature of beans in the radio frequency device is maintained within the range of 120-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com