A pixel unit and its preparation method

A pixel unit and epitaxial layer technology, applied in the field of pixel unit and its preparation, can solve the problems of large trench width, high cost, complex process, etc., and achieve the effects of reducing area waste, increasing fill factor, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a method for preparing a pixel unit, including the following steps:

[0041] Step 1, injecting P-type material into the P-type epitaxial layer around the edge of the pixel unit to form an isolation region;

[0042] In this embodiment, in order to prevent the preparation of the isolation region from affecting the shape of the N-type doped region of the photodiode, this embodiment uses three implants to keep the concentration of the P-type material uniform from top to bottom.

[0043] Wherein, the P-type material is an ion of a group III element or a compound of an ion of a group III element, such as boron ion.

[0044] Specifically include the following steps:

[0045] The first time: the energy of injecting P-type material is 150keV~300keV, and the dose of injecting P-type material is 5×10 11 cm -2 ~1.5×10 12 cm -2 , the inclination when injecting P-type material is 0°~2°;

[0046] The second time: the energy of injecting P-type material i...

Embodiment 2

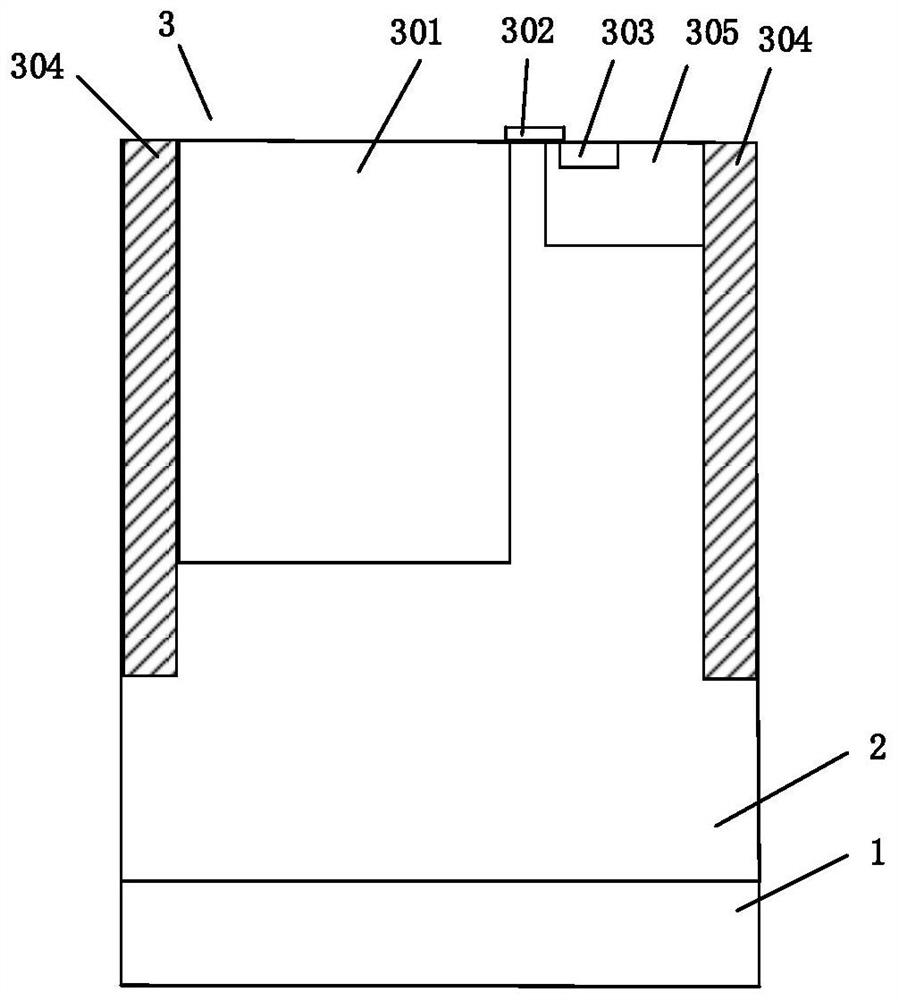

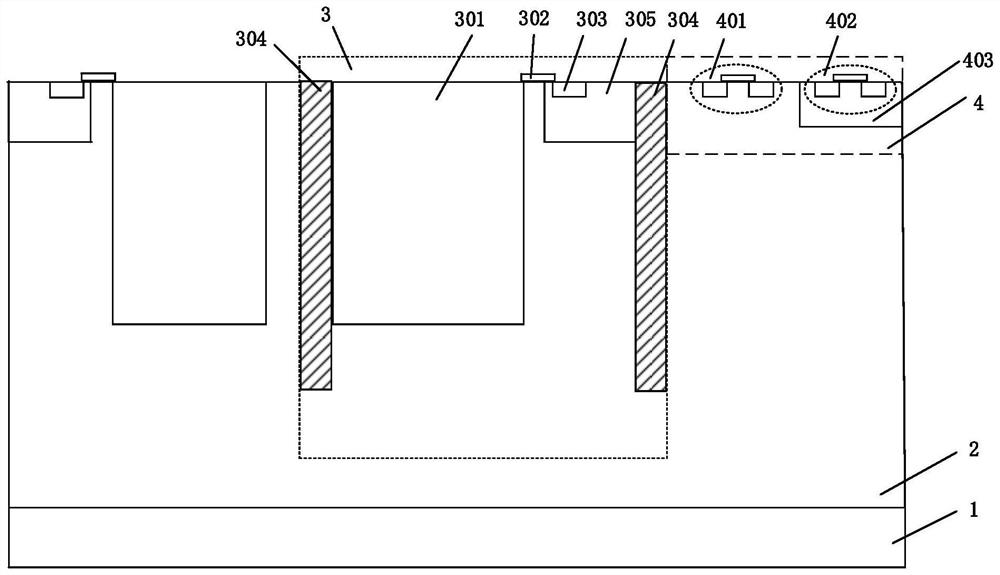

[0085] This embodiment provides a pixel unit, such as figure 1 , 2 As shown, it includes a P-type substrate 1 and a P-type epitaxial layer 2 arranged above the P-type substrate 1, and the upper part of the P-type epitaxial layer 2 is provided with an N-type doped region 301 and a P-well isolation region 305, so A floating diffusion node 303 is arranged on the upper part of the P-well isolation region 305;

[0086] The upper surface of the P-type epitaxial layer 2 is provided with a transmission gate 302;

[0087] A P-type isolation region 304 is provided between the pixel unit 3 and the adjacent pixel unit 5 and / or the logic circuit region 4;

[0088] The depth of the P-type isolation region 304 is not less than the depth of the N-type doped region 301 .

[0089] In this embodiment, both ends of the transfer gate 302 partially overlap with the N-type doped region 301 and the floating diffusion node 303, so that when the transfer gate 302 is turned on, that is, when a suffic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com