Sample for detecting strength of mould shell, manufacturing method of sample for detecting strength of mould shell, and strength detection method of sample for detecting strength of mould shell

A manufacturing method and strength detection technology, which is applied in the preparation of test samples, and the use of stable bending force to test the strength and strength characteristics of materials, etc., can solve the problem of improving the shell making process of castings and provide more reliable data and thickness There is no more intuitive and convenient method for intensity and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1: Fabrication of a shell strength sample corresponding to a certain oriented columnar crystal blade

[0041] 1) Press the test wax model and combine the modules, with 6 samples in each group;

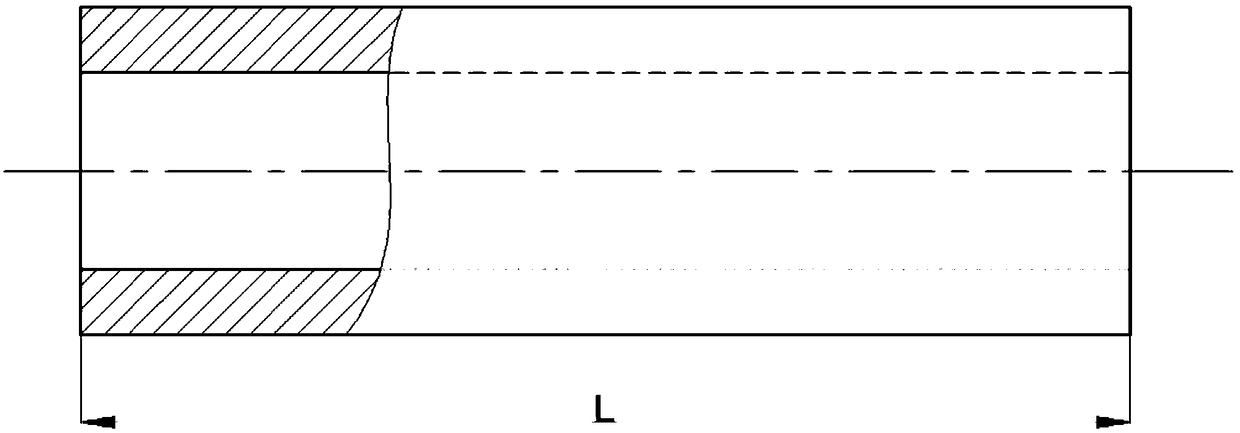

[0042] 2) According to the manufacturing process of the blade shell with 5 layers and the sealing layer and the oriented column crystal casting shell, the same process scheme is used for the sample wax model module to make the shell;

[0043] 3) Dewaxing the mold, and pre-baking the mold shell after placing it for 24 hours;

[0044] 4) Cut 6 samples from the formwork group;

[0045] 5) Place the sample in a flexural strength tester to test the room temperature and high temperature strength.

[0046] Specifically, the specific sample preparation process is as follows:

[0047] a. Use wax molds and wax presses to make solid cylindrical wax molds, process wax molds for making test samples for shell strength, and combine cylindrical wax molds into cylindrical wax mold gro...

Embodiment 2

[0053] Embodiment 2: Fabrication of an equiaxed crystal shell strength sample corresponding to a certain turbine rotor

[0054] 1) Press the test wax model and combine the modules, with 6 samples in each group;

[0055] 2) According to the 7 layers of the shell of the turbine rotor and the manufacturing process of the sealing layer and the equiaxed crystal casting shell, the same process scheme is used for the sample wax model module to make the shell;

[0056] 3) Dewaxing the mold, and pre-baking the mold shell after placing it for 24 hours;

[0057] 4) Cut 6 samples from the formwork group;

[0058] 5) Place the sample in a flexural strength tester to test the room temperature and high temperature strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com