Coaxial pulsation type stepless speed changing equipment

A continuously variable speed, coaxial technology, applied in mechanical equipment, transmission, transmission control and other directions, can solve the problems of small force, easy to slip, limited torque, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

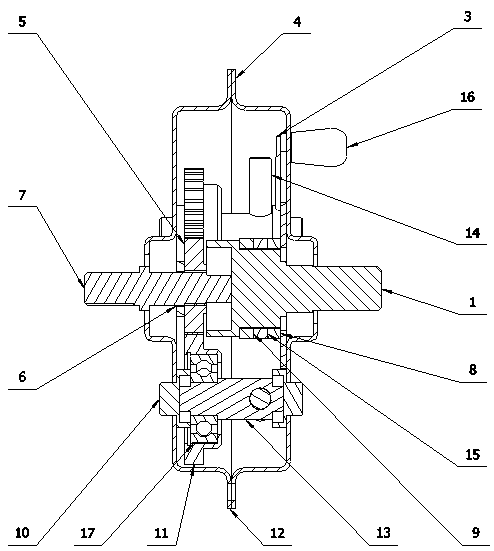

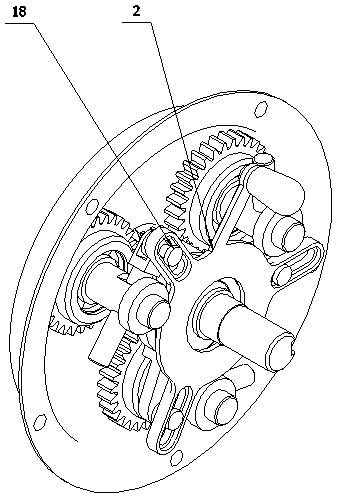

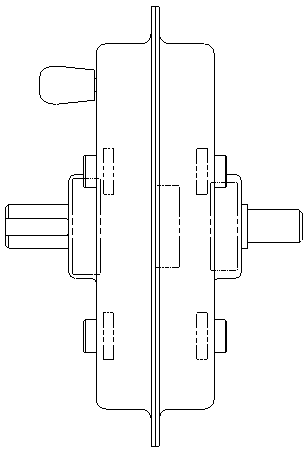

[0022] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0023] see Figure 1 to Figure 4 , Coaxial pulsating continuously variable transmission equipment includes: transmission shaft drive shaft 1, transmission control lever 2, adjustment nail 3, left end plate 4, spur gear II5, gear spacer 6, transmission shaft output shaft 7, and outer rocker 8 , inner rocking part 9, intermediate shaft bearing seat 10, spur gear I11, right end plate 12, stop shaft 13, swing lever 14, middle rocking part 15, twist cap 16, one-way bearing 17, sliding nail 18, described The center of the left end plate 4 is provided with a transmission shaft drive shaft 1, and the center of the right end plate 12 is provided with a transmission shaft output shaft 7. The left end plate 4 and the right end plate 12 are combined to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com