Vertical H-shaped steel four-face rust removal device

A H-shaped steel, vertical technology, applied in the direction of grinding machines, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of construction danger, time-consuming and labor-intensive, low efficiency, etc., to reduce labor intensity, improve work efficiency, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

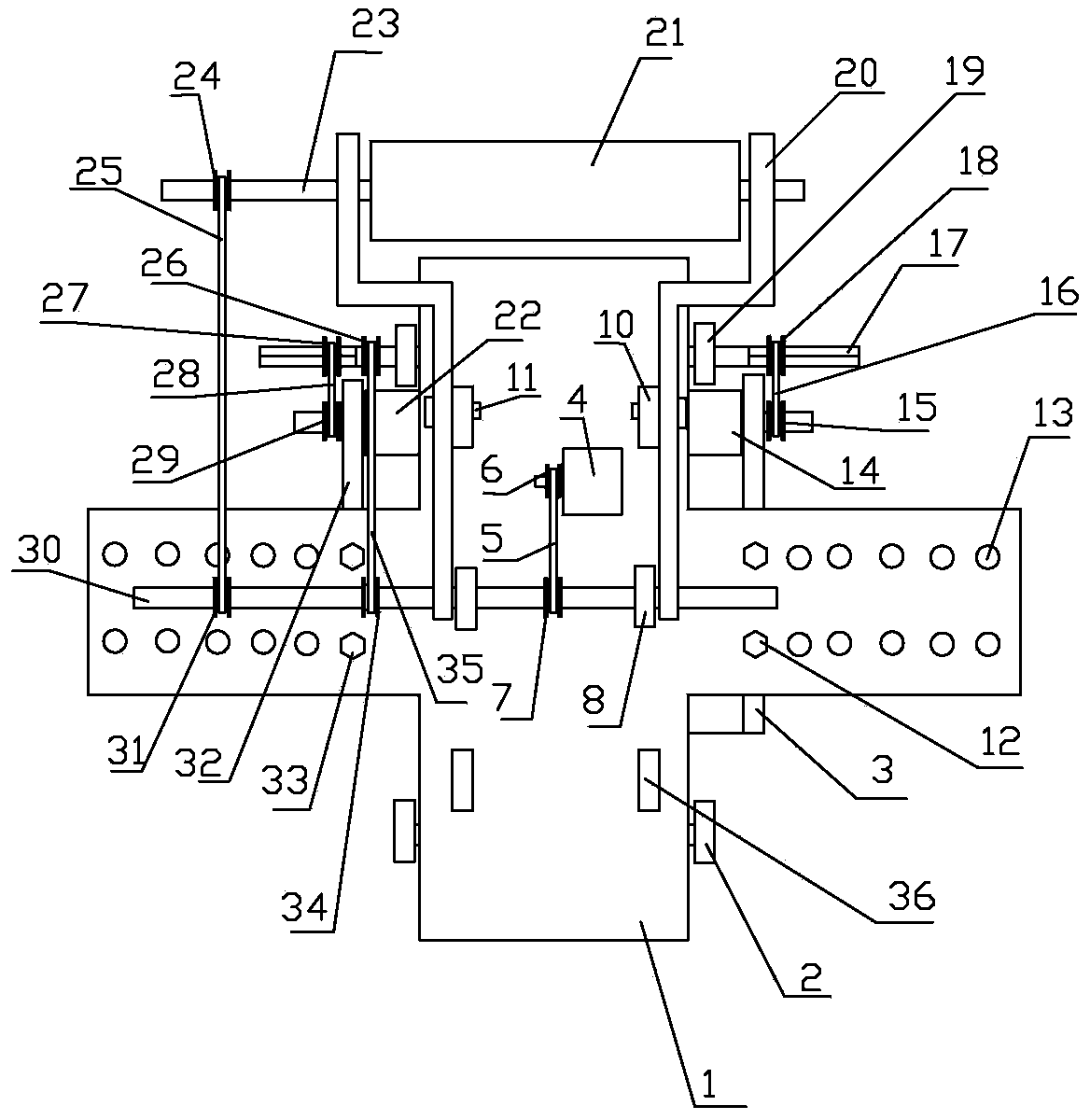

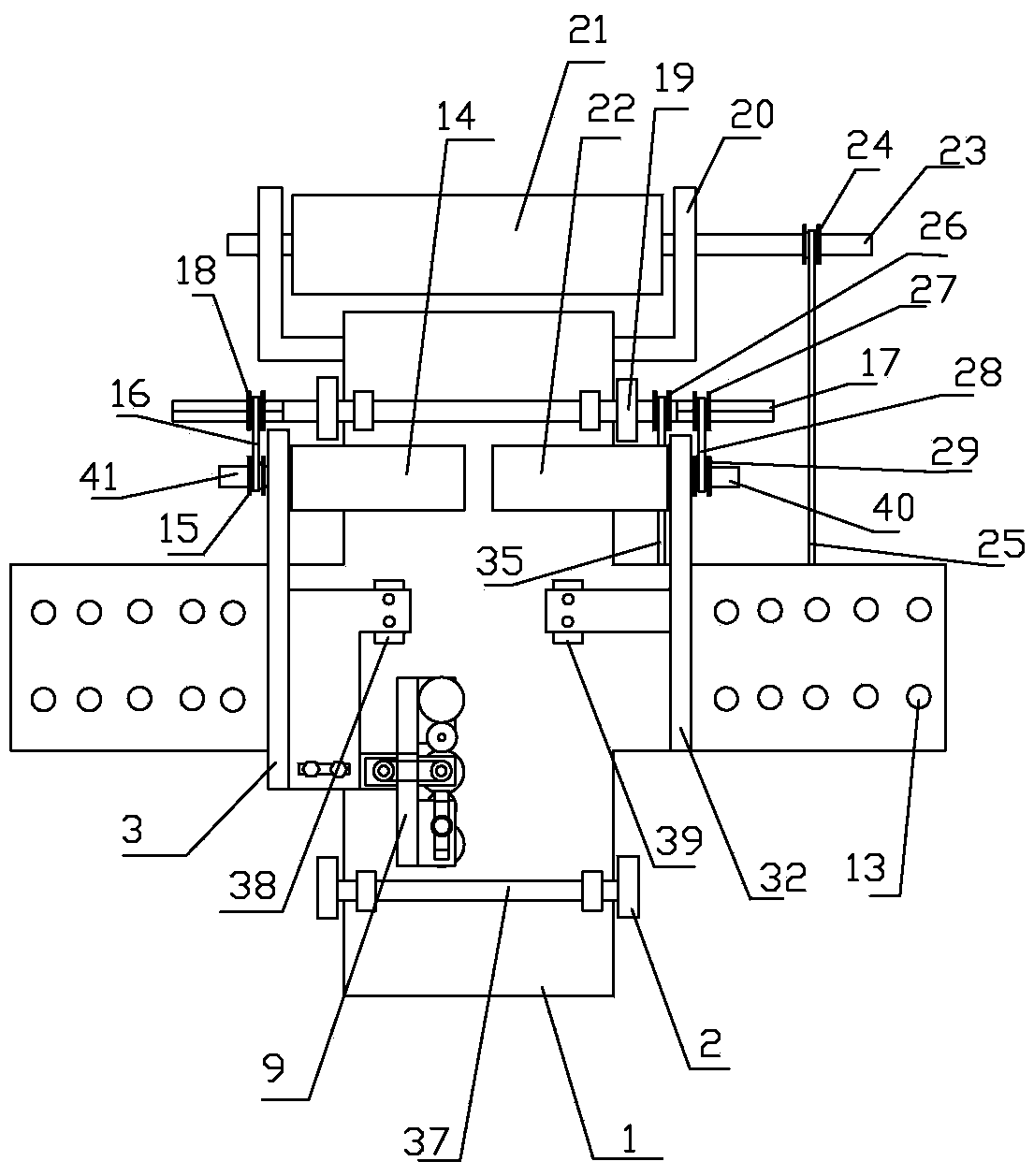

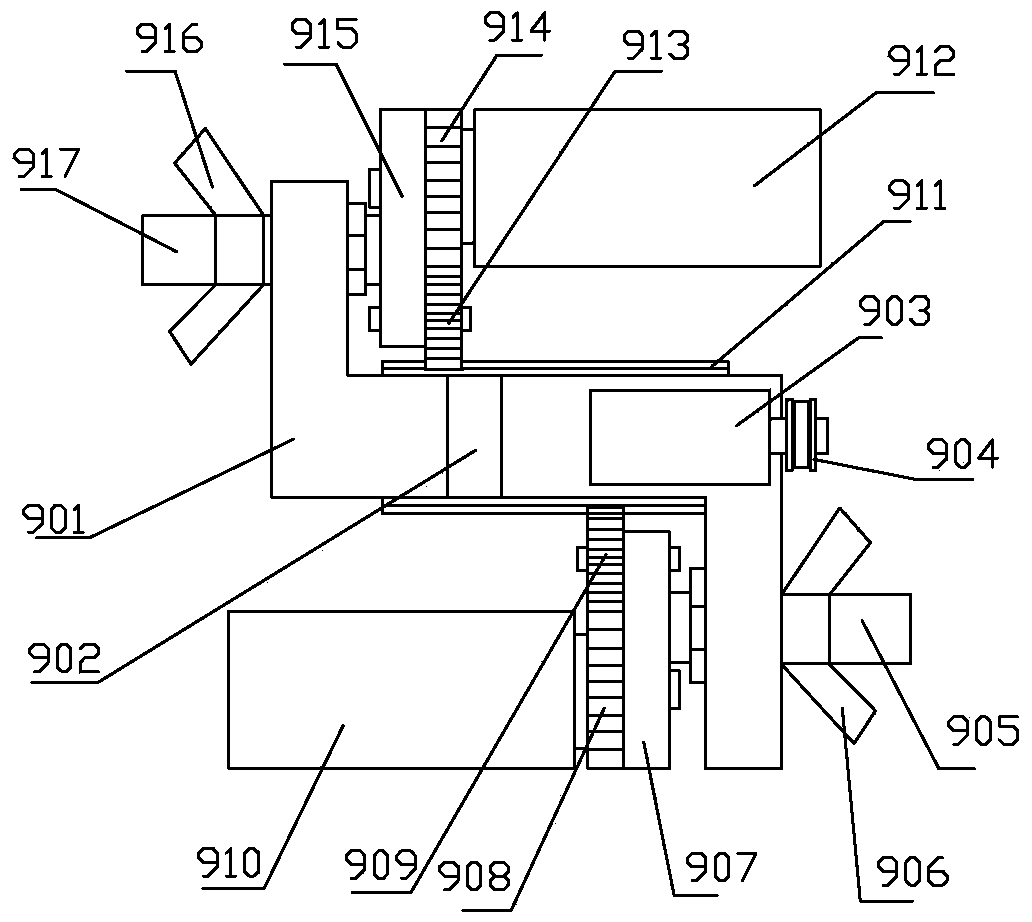

[0020] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5Make the present invention, this vertical H-beam four sides derusting device, comprises vehicle frame 1, No. 3 turning bar 17, front wheel 19, No. 4 turning bar 37, trailing wheel 2, motor and brush roller, is fixedly installed on the vehicle frame 1 There is a No. 1 motor 4, and the No. 1 motor 4 is connected with the PLC controller through wires, and the forward rotation, reverse rotation and rotating speed of the No. 1 motor 4 are controlled by the PLC controller. The front bottom plate of the vehicle frame 1 is provided with a No. 3 rotating rod 17, Two front wheels 19 are fixedly arranged on the No. 3 rotating rod 17, and the rear portion base plate of vehicle frame 1 is provided with No. 4 rotating rod 37 parallel with No. 3 rotating rod 17, and the two ends of No. 4 rotating rod 37 are fixedly installed respectively. There are rear wheels 2, two front wheels 19 and two rear wheels 2 are placed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com