A tea stirrer

A technology of tea and stir-frying, which is applied in the field of stir-frying devices, and can solve problems such as easy sore arms, hand burns, and reduced efficiency of tea stir-frying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

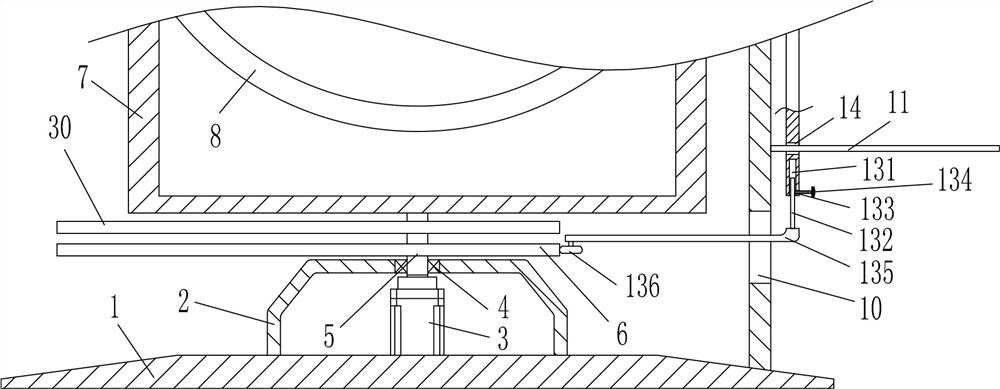

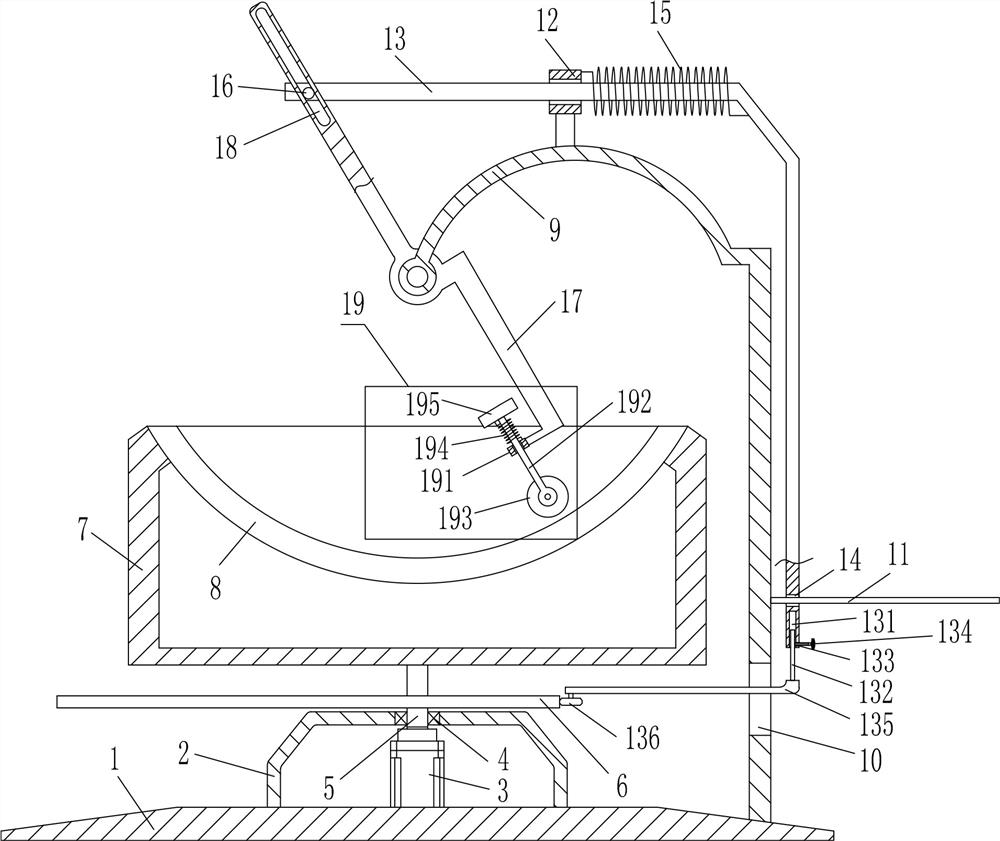

[0018] A tea stirrer, such as figure 1 As shown, it includes a support 1, a first bracket 2, a motor 3, a first bearing 4, a rotating shaft 5, a first cam 6, a support plate 7, a pot 8, a second bracket 9, a first slide bar 11, a first Sliding sleeve 12, second sliding rod 13, third sliding rod 132, first screw rod 134, first pole 135, roller 136, first tension spring 15, pin rod 16, swing rod 17 and telescopic device 19, bearing The top of 1 is equipped with a first support 2, and the support 1 is connected with the first support 2 by means of bolt connection, and the middle of the top of the first support 2 is embedded with a first bearing 4, and the rotating shaft 5 is installed in the first bearing 4, which can be The first cam 6 that makes the roller 136 move left and right is installed on the rotating shaft 5, and the motor 3 that can drive the first cam 6 to rotate is installed in the middle of the top of the support 1, and the motor 3 is connected with the support 1 by...

Embodiment 2

[0020] A tea stirrer, such as figure 1As shown, it includes a support 1, a first bracket 2, a motor 3, a first bearing 4, a rotating shaft 5, a first cam 6, a support plate 7, a pot 8, a second bracket 9, a first slide bar 11, a first Sliding sleeve 12, second sliding rod 13, third sliding rod 132, first screw rod 134, first pole 135, roller 136, first tension spring 15, pin rod 16, swing rod 17 and telescopic device 19, bearing The top of 1 is equipped with a first bracket 2, the middle of the top of the first bracket 2 is embedded with a first bearing 4, the rotating shaft 5 is installed in the first bearing 4, and the first cam 6 that can make the roller 136 move left and right is installed on the rotating shaft 5 The motor 3 that can drive the first cam 6 to rotate is installed in the middle of the top of the support 1, the motor 3 is located in the first support 2, the top of the output shaft of the motor 3 is fixedly connected with the bottom end of the rotating shaft 5,...

Embodiment 3

[0023] A tea stirrer, such as Figure 1-2 As shown, it includes a support 1, a first bracket 2, a motor 3, a first bearing 4, a rotating shaft 5, a first cam 6, a support plate 7, a pot 8, a second bracket 9, a first slide bar 11, a first Sliding sleeve 12, second sliding rod 13, third sliding rod 132, first screw rod 134, first pole 135, roller 136, first tension spring 15, pin rod 16, swing rod 17 and telescopic device 19, bearing The top of 1 is equipped with a first bracket 2, the middle of the top of the first bracket 2 is embedded with a first bearing 4, the rotating shaft 5 is installed in the first bearing 4, and the first cam 6 that can make the roller 136 move left and right is installed on the rotating shaft 5 The motor 3 that can drive the first cam 6 to rotate is installed in the middle of the top of the support 1, the motor 3 is located in the first support 2, the top of the output shaft of the motor 3 is fixedly connected with the bottom end of the rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com