Cutting and milling dual-purpose permanent magnet servo motor

A permanent magnet servo motor, a dual-purpose technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of affecting the service life of processing equipment, the accuracy is greatly affected by the quality, and the milling dimensional accuracy is insufficient, so as to save installation Time, structure design is simple and reasonable, and the effect of high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments (embodiments). The specific embodiments described here are only used to explain the present invention, but not as a basis for limiting the present invention.

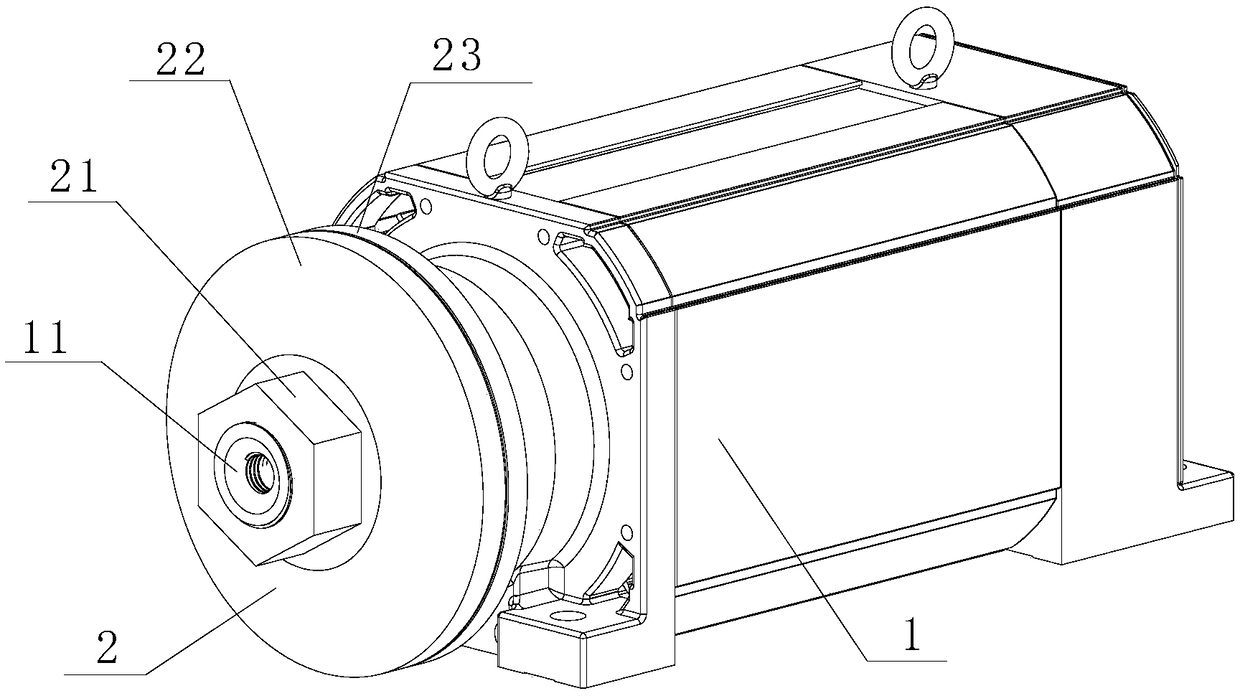

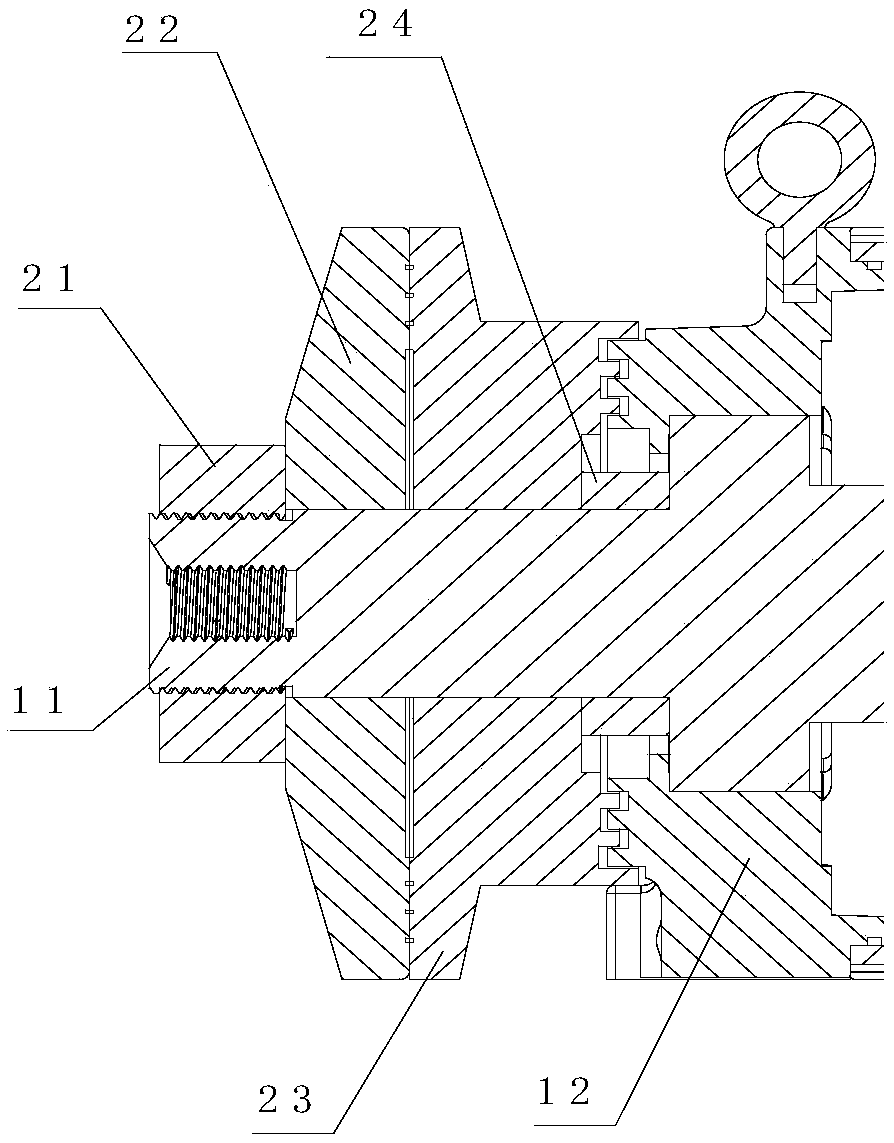

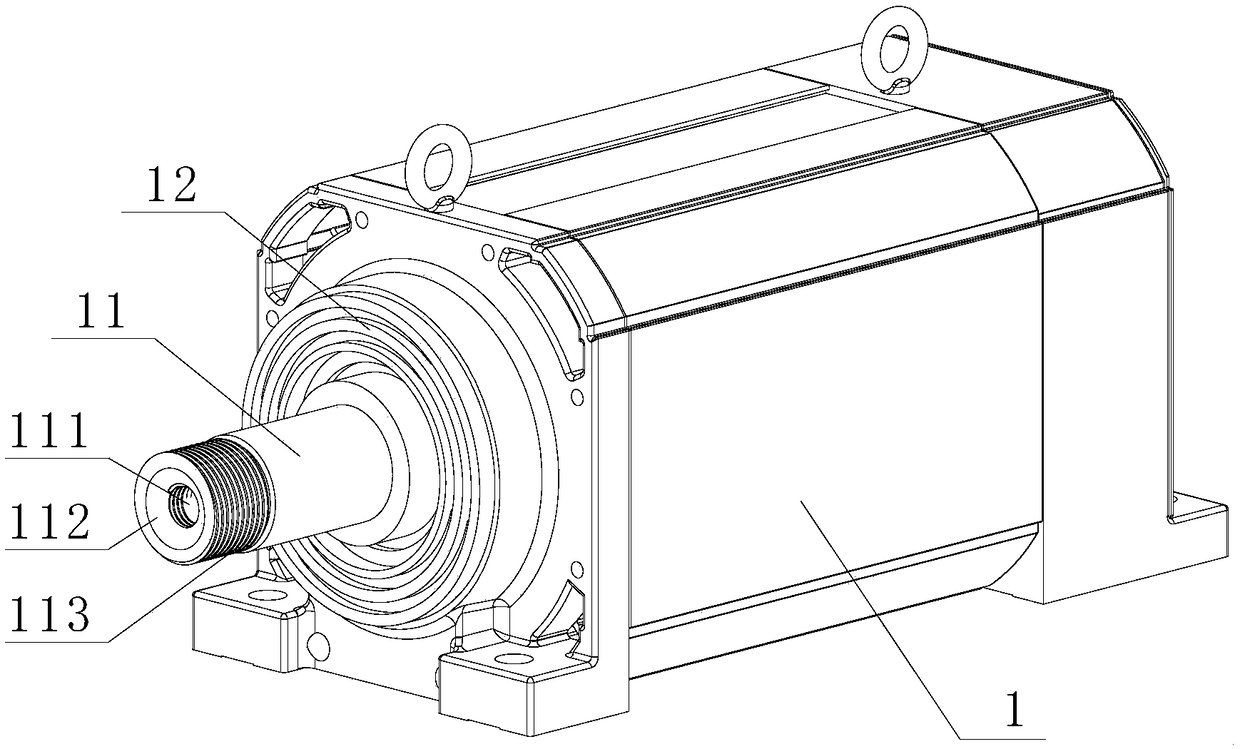

[0032] see Figure 1-13 , the dual-purpose permanent magnet servo motor for cutting and milling of the present invention includes a motor body 1 and a cutting blade clamping device 2; surface 112 and milling cutter mounting surface 111, the outer periphery of the front end of the motor shaft 11 has a locking device mounting surface 113; The disc 23 , the front clamping disc 22 of the cutting blade and the locking member 21 of the clamping device;

[0033] As a specific embodiment, the mounting surface 113 of the locking device is screw-fitted with the locking member 21 of the clamping device. It is convenient to disassemble and adjust the clamping force of the cutting blade clamping devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com