Vacuum load switch

A vacuum load and switch technology, applied in the direction of electric switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc., can solve problems such as laborious installation, reduce production costs, and micro-deformation, and achieve control accuracy and stability. The structural design is simple and reasonable, and the effect of improving work safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

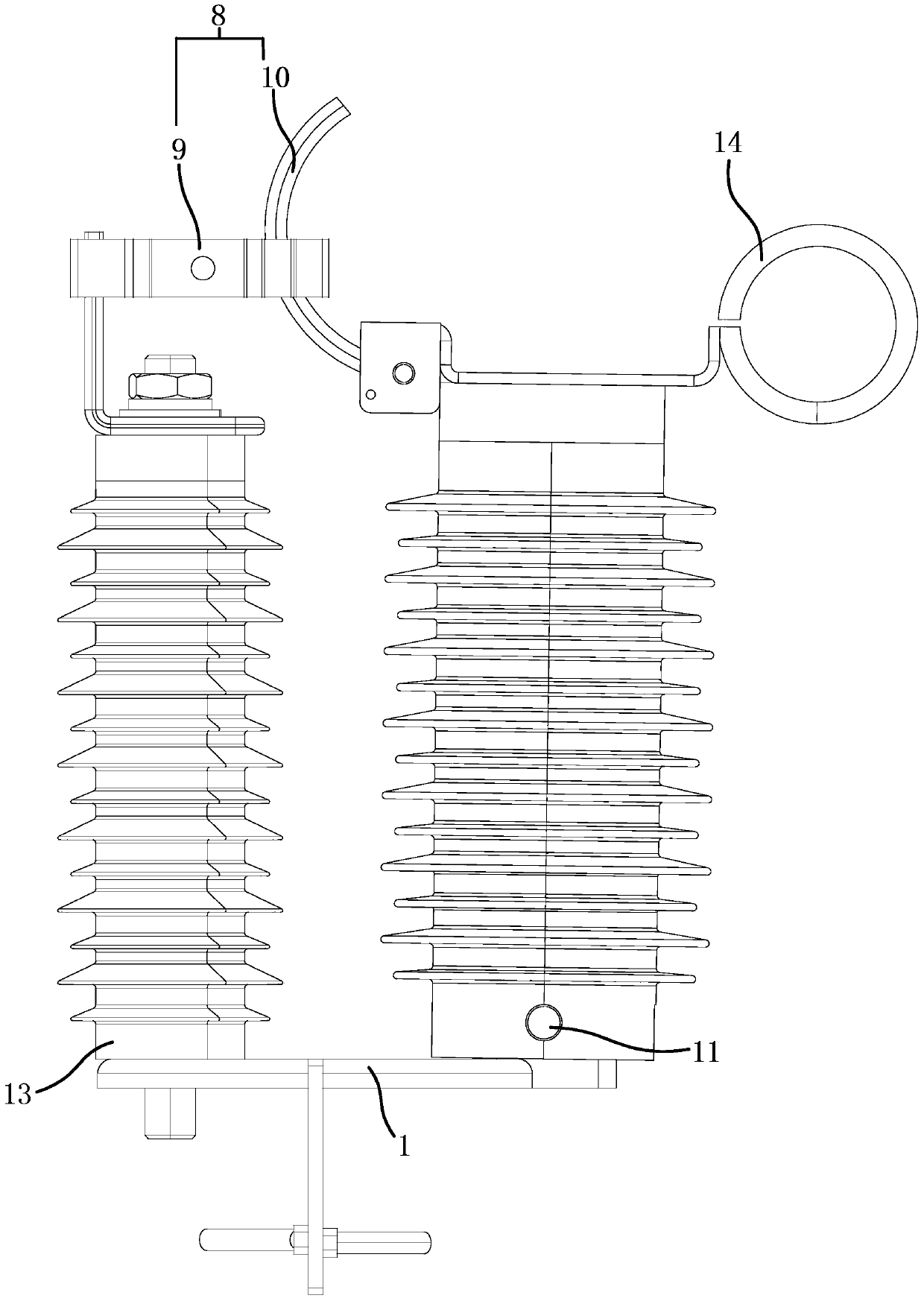

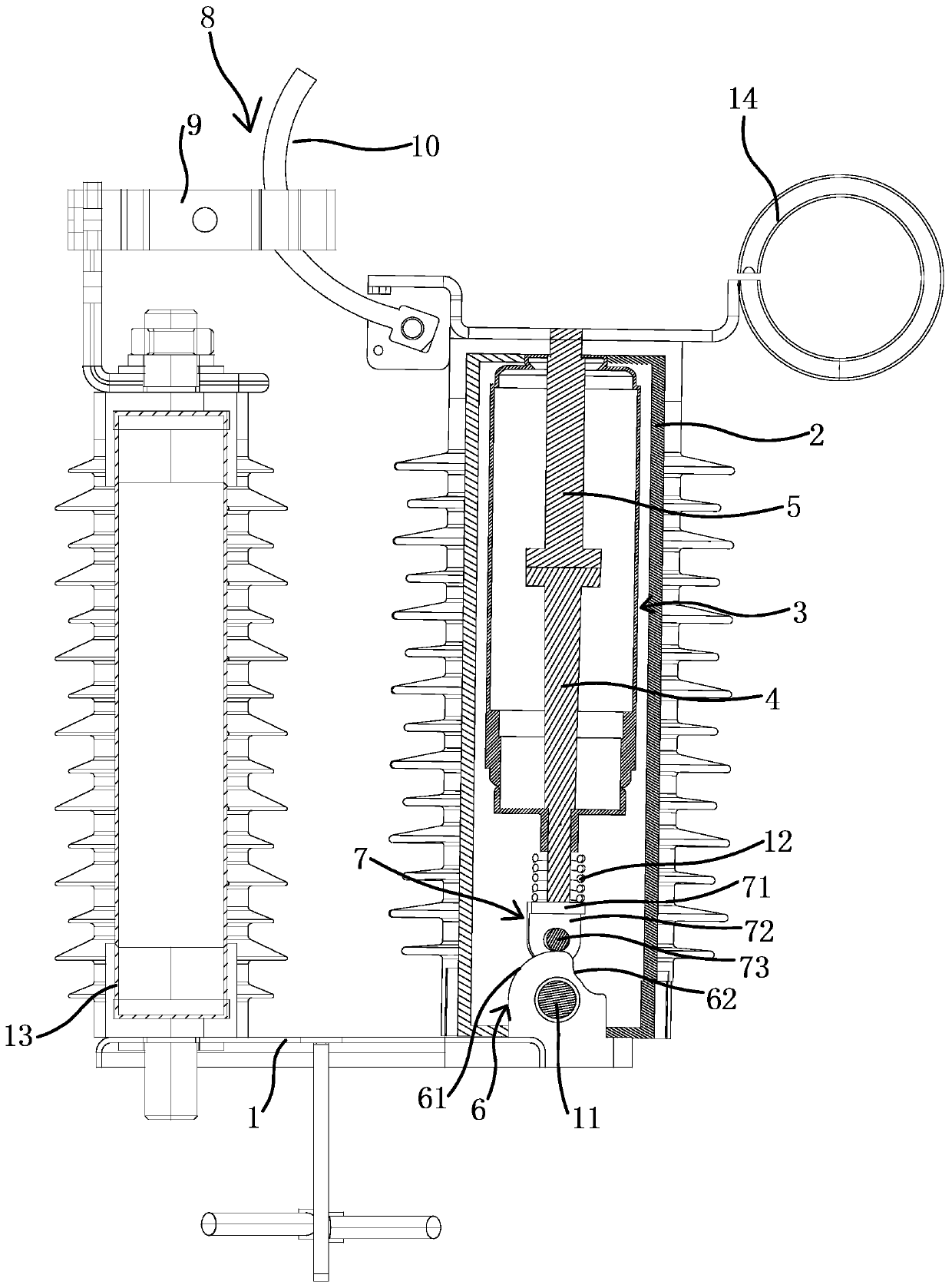

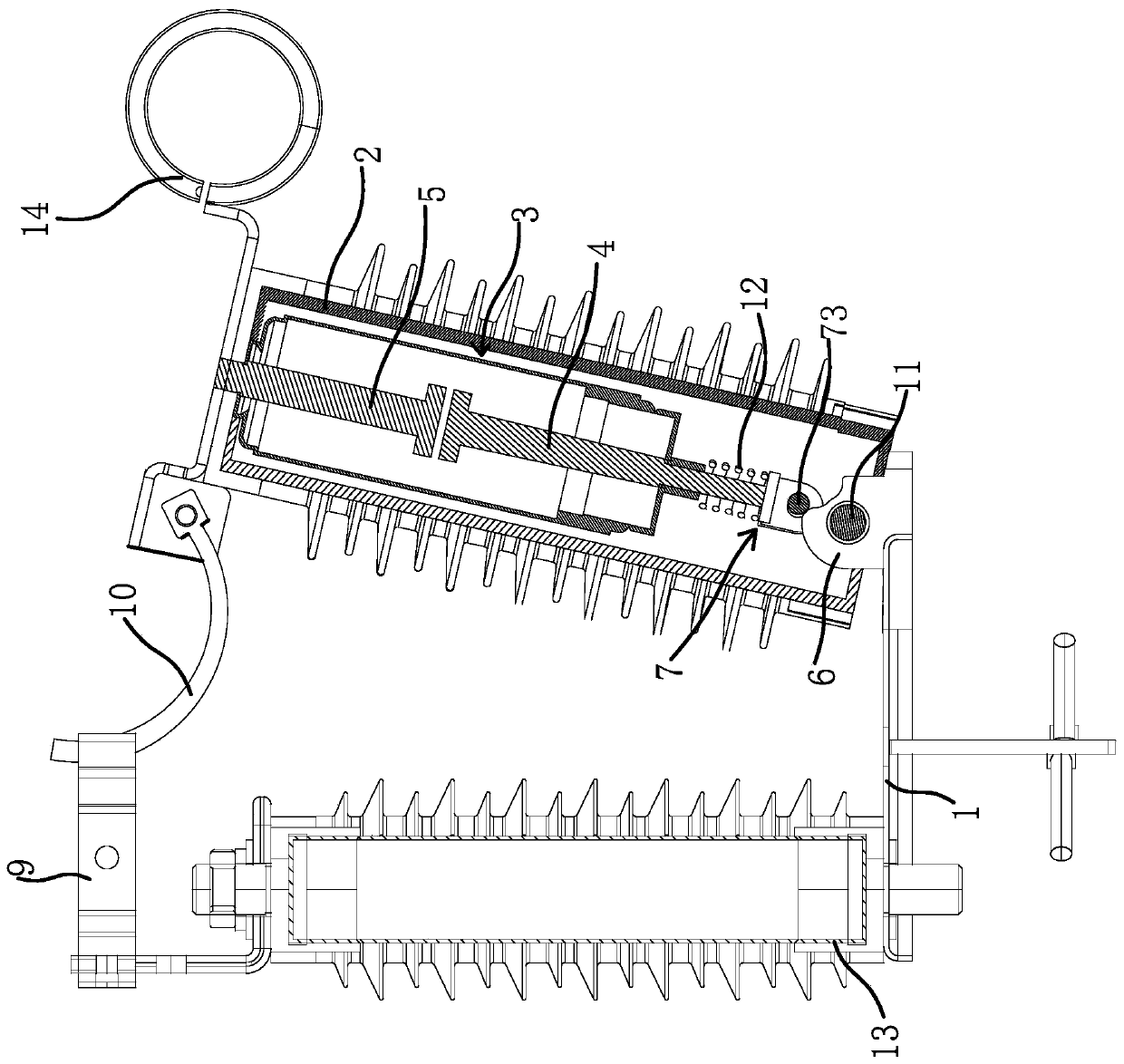

[0026] like figure 1 and figure 2 As shown, this embodiment includes a base 1, a cylindrical shell 2 and a conductive column 13 arranged at opposite intervals, an insulating sleeve is sleeved on the shell 2 and the conductive column 13, and the lower end of the shell 2 is hinged with the base 1, It is convenient for the housing 2 to rotate on the base 1 . The housing 2 is provided with a vacuum interrupter 3, the vacuum interrupter 3 includes a vacuum chamber, and a static contact rod 5 and a movable contact rod 4 in contact with the static contact rod 5 are inserted into the vacuum chamber. Moving up and down along the vacuum chamber, the housing 2 is also provided with a return spring 12 that keeps the movable contact rod 4 away from the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com