Three-coordinate measuring system and method

A three-coordinate measurement and probe technology, used in measurement devices, mechanical measurement devices, general control systems, etc., can solve the problems of reduced measurement efficiency, heavy measurement workload, slow search, etc., to reduce abnormal damage and improve detection. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

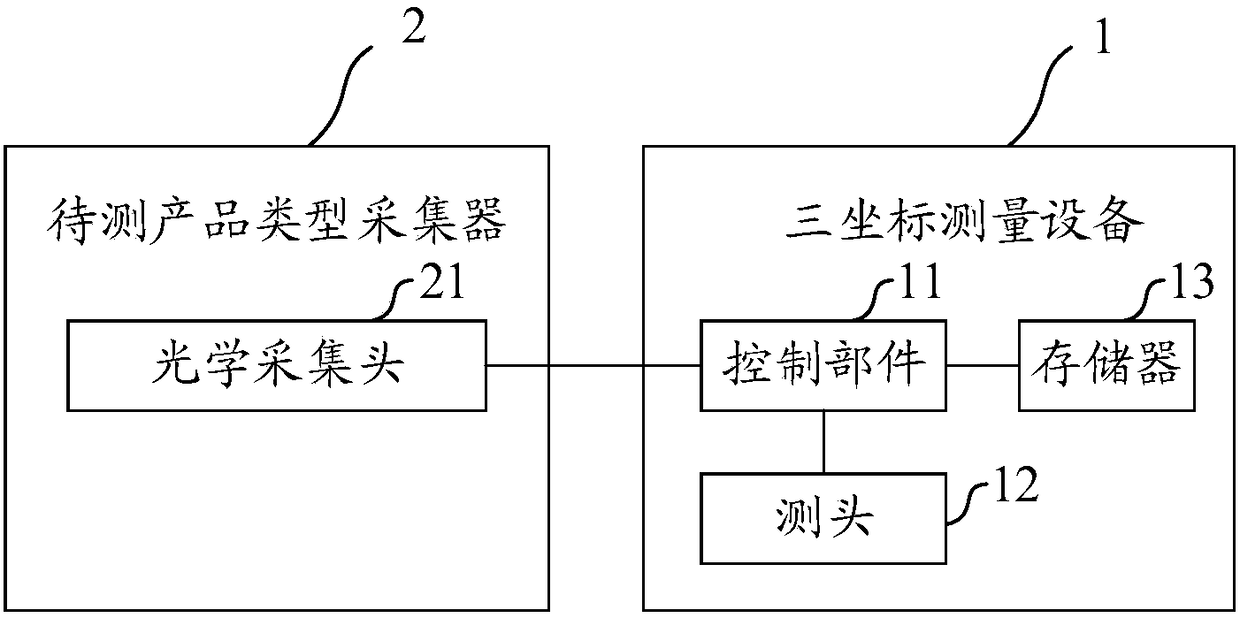

[0039] like figure 1 As shown, the embodiment of the present invention provides a three-coordinate measuring system, which includes a three-coordinate measuring device 1 and a product type collector 2 to be tested; the three-coordinate measuring device 1 is provided with a probe 12 and a control unit 11. The control part 11 is electrically connected to the probe 12;

[0040] The product type collector 2 to be tested includes an optical collection head 21 capable of scanning graphic identifiers; the optical collection head 21 is electrically connected to the control unit 11;

[0041] The control part 11 obtains the product type of the product to be tested according to the graphic identifier scanned by the optical collection head 21, and calls the corresponding measurement program according to the obtained product type, and then the control part 11 controls the movement of the probe 12 to the measured product through the called measurement program. Measure the product to be tes...

Embodiment 2

[0054] like image 3 As shown, the embodiment of the present invention also provides a three-coordinate measurement method, which can be executed by the control component of the three-coordinate measurement system, and the method includes:

[0055] Step 301: Obtain the product type of the product to be tested according to the graphic identifier scanned by the optical collection head;

[0056] Specifically, the acquisition of the product type of the product to be tested according to the graphic identifier scanned by the optical collection head includes:

[0057] scanning the graphic identifier placed within the scanning range of the optical collection head through the optical collection head;

[0058] The product type of the product to be tested is obtained according to the pattern of the graphic identifier obtained by scanning the optical collection head.

[0059] Step 302: call a preset measurement program according to the acquired product type;

[0060] Step 303: Control ...

Embodiment 3

[0068] like Figure 4 As shown, the embodiment of the present invention also provides a three-coordinate measurement method of an aluminum alloy wheel hub, the method comprising:

[0069] Step 401: The control part of the three-coordinate measuring device instructs the inspection instruction generation device to issue an inspection instruction according to the storage of the aluminum alloy wheel hub;

[0070] Step 402: The control component instructs the inspection work order printing device to print a size inspection sheet according to the inspection instruction, and at the same time, the control component instructs the identifier printing device to print a self-adhesive barcode label;

[0071] Specifically, the control unit instructs the inspection work order printing device to print a dimensional inspection sheet corresponding to the aluminum alloy wheel hub to be tested (such as Figure 6 shown), and at the same time, the control unit instructs the identifier printing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com